The description says 150mm bolt pattern. Won't fit either the hub or the disc.Gary. I think I found the Ebay spacer maker

https://www.ebay.com/itm/153831357478

On a sie note, I discussed mu situation with MM at 650 central. He said my rotor has 25mm of offset, and a 77 and newer has 17 thus a difference of 8mm.

Here is a 7mm spacer for an SR500/400, so how crucial is that last 1mm?

https://www.motolanna.com/ourshop/p...Spacer-7mm-Yamaha-SR500-SR400-Late-Model.html

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need a replacement front rotor, 1976 C

- Thread starter Norton7d

- Start date

You will need 7mm PLUS the addional or about 12mm total m/l. Which means you need a spacer with an offset or Z shape cuz the rotor will be out beyond the hub. The newer rotors just catch the hub center with a 7mm spacer. You can move the caliper in also. Its not preferred but mikes did it with their replacement rotor.

Norton7d

XS650 Junkie

The 76 caliper is twin piston, thus its backside doesnt allow much wiggle room before it hits the spokes so I dont think moving the caliper in is a viable solution to make up for the differences in offset?

Last edited:

Norton7d

XS650 Junkie

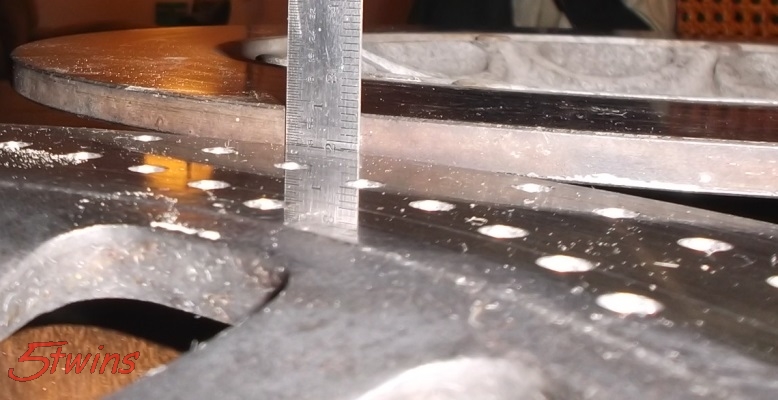

On the old and new style discs I compared, I only found about 5mm of difference in the offset .....

Since the discs are only 7mm thick, if the offset difference was 8mm, the older disc would sit above the newer one. As you can see in the pics, it clearly doesn't. Also, the offsets on these appear to be 19 and 24mm.

Thanks 5T... The more info the better.

Norton7d

XS650 Junkie

Imteresting, does this mean a new rotor ID is larger then the hub OD?You will need 7mm PLUS the addional or about 12mm total m/l. Which means you need a spacer with an offset or Z shape cuz the rotor will be out beyond the hub. The newer rotors just catch the hub center with a 7mm spacer. You can move the caliper in also. Its not preferred but mikes did it with their replacement rotor.

The 76 caliper is twin piston, thus its backside doesnt allow much wiggle room before its the spokes so I dont think moving the caliper in is a viable solution to make up for the differences in offset?

That could be right. Typical hot rodder's rat hole, change ONE stinking thing and the whole vehicle has to be modded before you're done.

No the rotor gets moved out so far it no longer centers (sits) on the hub. the Z shape can be tricky cuz the cross section is thin.But it's been done a time or two. There was a great machinist on the east coast did it a few years back on a cool custom XS IIRC.Imteresting, does this mean a new rotor ID is larger then the hub OD?

No the rotor gets moved out so far it no longer centers (sits) on the hub. the Z shape can be tricky cuz the cross section is thin.But it's been done a time or two. There was a great machinist on the east coast did it a few years back on a cool custom XS IIRC.

It can be done, like Gary says gotta be careful

Don't recall the offset, Brembo disc and caliper on my '77

Cool Beags!

A blast from the past thread Osteoderm really was over the top.

http://www.xs650.com/threads/good-h...nother-build-thread.13561/page-13#post-178390

A blast from the past thread Osteoderm really was over the top.

http://www.xs650.com/threads/good-h...nother-build-thread.13561/page-13#post-178390

Norton7d

XS650 Junkie

Well at this point, dont know what to do, no bolt on replacements ...and I'm not a machinest.

MM at 650 central said I shouldnt have the rotor turned, instead it is to be ground flat but people that do that kind of work are hard to find as its a dead industry.

MM at 650 central said I shouldnt have the rotor turned, instead it is to be ground flat but people that do that kind of work are hard to find as its a dead industry.

there was a guy grinding and putting holes in rotors on fleabay, northwest, Washington state?

If DB can't come through I think I have an extra or two.

Here's a shop doing it. https://truedisk.net/

Though I have run into a warped rotor or two, more common is dirt other stuff in the way of proper flat mounting to the wheel.

If DB can't come through I think I have an extra or two.

Here's a shop doing it. https://truedisk.net/

Though I have run into a warped rotor or two, more common is dirt other stuff in the way of proper flat mounting to the wheel.

Well at this point, dont know what to do, no bolt on replacements ...and I'm not a machinest.

MM at 650 central said I shouldnt have the rotor turned, instead it is to be ground flat but people that do that kind of work are hard to find as its a dead industry.

ANY shop with a surface grinder can do it.

you don’t need an od/Id grinder.

A Blanchard would be ideal - probably take 15 minutes to do.

not sure where you are but if you look in Orange County on any industrial block there is a shop that can do it.

If they had any years of service, they could even grind it on a mill, or dare I say drill press with a traveling vice.

Specific grind shop

great western grinding in Huntington Beach

or western grinding in Santa Clara.

Norton7d

XS650 Junkie

Thanks WideAwake..I'm in Sacramento, not so far from Santa Clara. I can eith deliver or mail.

Will pursue this.

Will pursue this.

Surface grinding can lead to brake grab as it crosses the directional changes in the linear grind finish, for awhile, until the rotor "brakes in" lol..

If you'd like, Norton 7d, I'd attempt either a low rpm lathe turn or a flat milling circular movement with a fly cutter.

At my work shop. Free of charge for the attempt.

-R

ps (*there is hardly anybody as accurate as "machine")

If you'd like, Norton 7d, I'd attempt either a low rpm lathe turn or a flat milling circular movement with a fly cutter.

At my work shop. Free of charge for the attempt.

-R

ps (*there is hardly anybody as accurate as "machine")

Attachments

Norton7d

XS650 Junkie

Thanks Randy...I might take you up on this. I would buy a used disc off ebay and have it shipped right to you.

This way if it dont work out, I still would have a working front brake.

This way if it dont work out, I still would have a working front brake.

Have to admit, a spinning "blanchard" grinder does sound good. I do not have access to that.

My offer stands to attempt regardless.. -R

My offer stands to attempt regardless.. -R

Well at this point, dont know what to do, no bolt on replacements ...and I'm not a machinest.

MM at 650 central said I shouldnt have the rotor turned, instead it is to be ground flat but people that do that kind of work are hard to find as its a dead industry.

ANY shop with a surface grinder can do it.

you don’t need an od/Id grinder.

A Blanchard would be ideal - probably take 15 minutes to do.

not sure where you are but if you look in Orange County on any industrial block there is a shop that can do it.

If they had any years of service, they could even grind it on a mill, or dare I say drill press with a traveling vice.

Specific grind shop

great western grinding in Huntington Beach

or western grinding in Santa claret

Surface grinding can lead to brake grab as it crosses the directional changes in the linear grind finish, for awhile, until the rotor "brakes in" lol..

If you'd like, Norton 7d, I'd attempt either a low rpm lathe turn or a flat milling circular movement with a fly cutter.

At my work shop. Free of charge for the attempt.

-R

ps (*there is hardly anybody as accurate as "machine")

I ran a carbide grind shop for about 5 years before I moved away.

Typically a rotor or the like would go into the Blanchard but if it couldn’t for whatever reason

it may have gotten done on the surface grinder. To avoid the direct/cross cuts we would hold the part in an indexing head. Grind it straight across to get the bulk and then run it under the wheel at 0 and spin the chuck. Move in spin the chuck until we hit center. That way your “grain” goes round and round.

If it was mine I’d face it on the lathe. Done a handful of lambretta ones that way and never had any issues.

Very likely to face a mandrel true after creating a bolt circle which the cast rotor center piece will bolt to. This should keep the rotor faces parallel to the rotor mount plane. Looking forward to hearing the rotor try to sing while setting up for a finish pass cut. Outward in or inward out ? IDK yet. Intetesting project to try.If it was mine I’d face it on the lathe.