plane_ben

XS650 Junkie

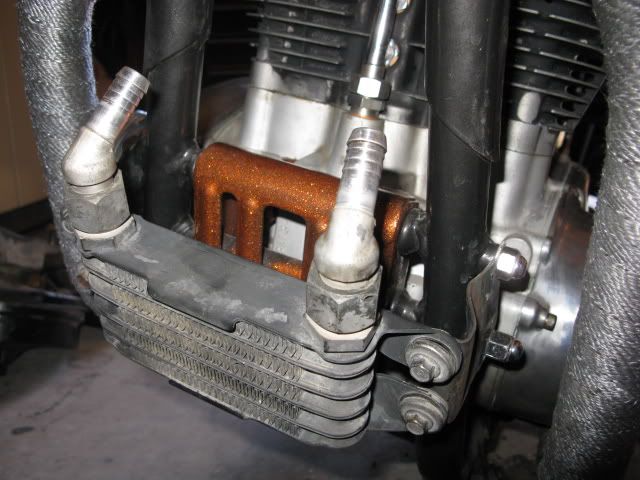

Deceided to do an XSJohn oil cooler mod to my chopper. Located two XS750 oil coolers complete with lines at the local junk yard, then went to town. First I flattened out the stock mounting plates that were for the XS750, and filed out the holes so I could get an upright angle more in line with the frame. I mounted the oil cooler on the two front mount bolts on the out side of the frame rails.

Once that was done, I made the top end oil restricter, and opened up the old restricter union that screws into the case. Here are pictures of the parts. Left is the opened restricter union, middle is the new restricter piece, and right is the old restricter union for comparison. Then the top end oil line with restricter JB Welded in, and the bottom oil line installed. Just need to go get some suitable 1/2" I.D. oil line, and hose clamps tomarrow and install them. Should be ready to go. I also filled the oil cooler with oil.

Once that was done, I made the top end oil restricter, and opened up the old restricter union that screws into the case. Here are pictures of the parts. Left is the opened restricter union, middle is the new restricter piece, and right is the old restricter union for comparison. Then the top end oil line with restricter JB Welded in, and the bottom oil line installed. Just need to go get some suitable 1/2" I.D. oil line, and hose clamps tomarrow and install them. Should be ready to go. I also filled the oil cooler with oil.