Lluber

Noob

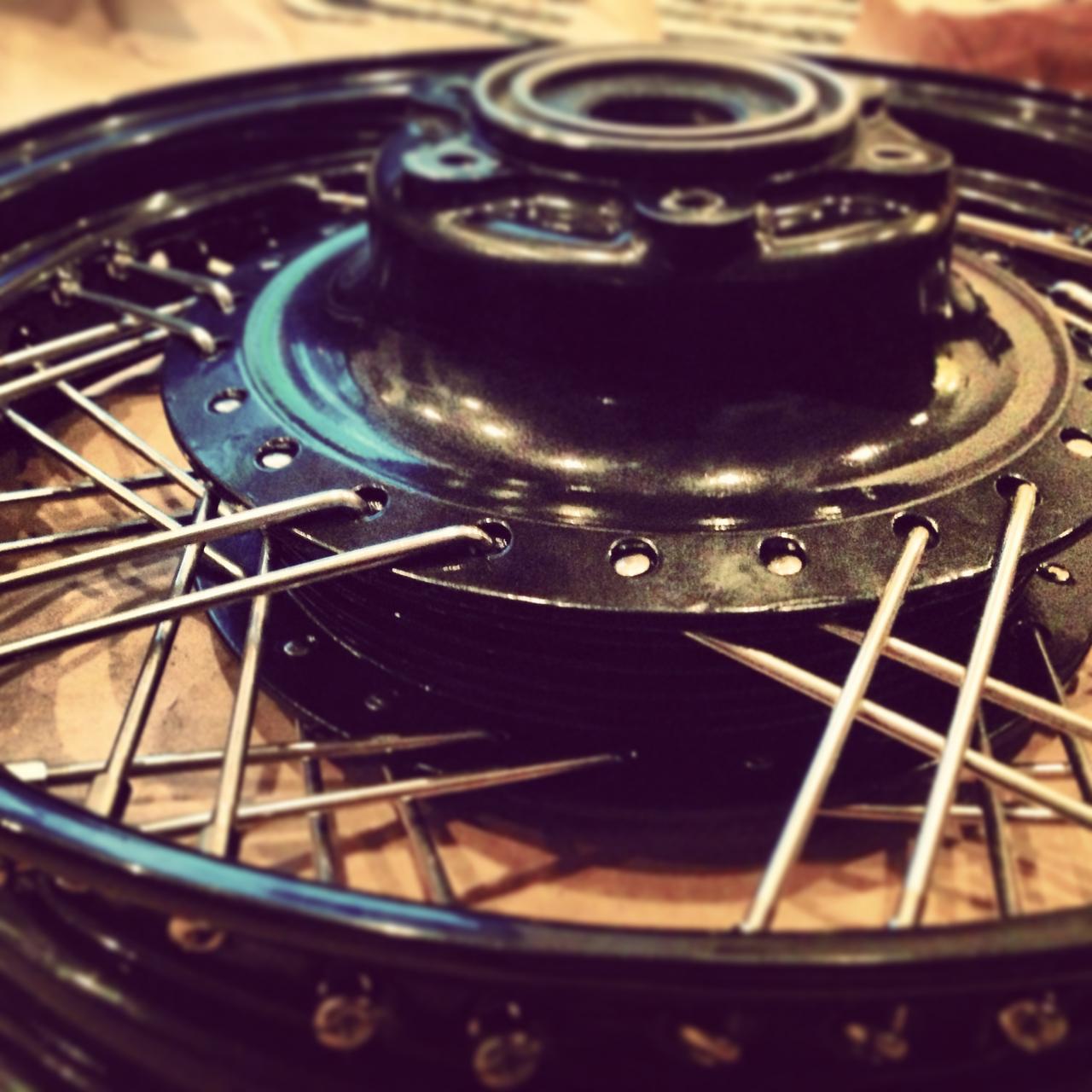

I'm about to do my wheels on my bike (83' heritage special) Starting with the back wheel 1st as its a mess. Needs to be trued and balanced.

I like the look of the black rims & hub.

I know I'm not painting them myself. Recently helped a friend and after all the work we did the paint flaked and we ended up getting them powder coated anyway. huge pain in the arse.

So, do I get my stock rim powder coated (local guy does them for 80ish per) not sure if he would even bother with the spokes as they might be to tedious. Or, I could pick up a new rim from mikes or somewhere else and lace it up with my stock spokes?

Thanks guys.

I like the look of the black rims & hub.

I know I'm not painting them myself. Recently helped a friend and after all the work we did the paint flaked and we ended up getting them powder coated anyway. huge pain in the arse.

So, do I get my stock rim powder coated (local guy does them for 80ish per) not sure if he would even bother with the spokes as they might be to tedious. Or, I could pick up a new rim from mikes or somewhere else and lace it up with my stock spokes?

Thanks guys.

that would make for a rather unpleasant holiday with the in-laws!

that would make for a rather unpleasant holiday with the in-laws!