Here are the (uninspiring) photos from last time I was in Somerset. I'm just negotiating storage space in London so I should be able to bring the bike up soon.

New rear shock washers made up in 304 stainless. Not much to look at but at least they won't rust.

New folding footrests fitted. Again, not very exciting but at least they're small and light (they were also cheap - £8 on Ebay brand new!).

URL=http://s1099.photobucket.com/user/zachary_osborne/media/Untitled2.jpg.html]

[/URL]

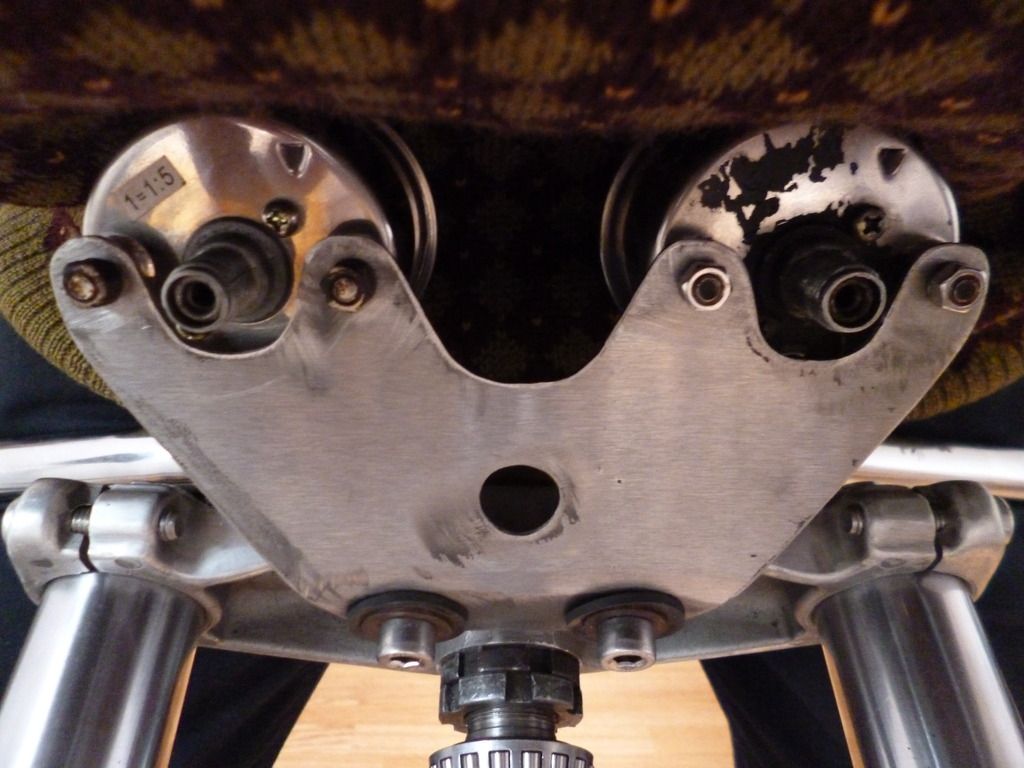

New 12.7mm master cylinder from an Aprilia SR50 moped (Grimeca). I think I'd like to try a 14mm as there still seems to be a bit too much travel at the bar for my liking. Let me know if anyone knows a usable 14mm master cylinder.

URL=http://s1099.photobucket.com/user/zachary_osborne/media/Untitled.jpg.html]

[/URL]

Quick shot of the complete front end. The bike rides really nicely with the new front end. It looks to be about 15mm lower than the standard forks. They are much smoother and have far better damping.

Here's another side shot. Really, really need to replace the haggard old Custom seat. A new seat with a flatter profile would look so much nicer. New pipes are looking good (although I need to fabricate new mounting brackets.

Revisiting my to-do list...

COMPLETE

- Test TX650 tank for leaks

- Fit new taps and replace fuel hose and filters

- Fit and plumb in front brake master cylinder.

- Replace footrests

- Fit new rear shock washers

- Check over front end and threadlock as required.

- File down new steering stops

- Fit new stainless steel headers with temporary brackets

- Top up oil and add fuel.

- Ride to MOT centre and achieve a faultless MOT (accept for the advisory for not having lights).

STILL LEFT TO DO

- Weld on rear tank mount

- Clean carbs

- Change oil and fit Smedspeed spin-on filter plate

Looks great! Yes, 13 mm minimum thickness is overkill.

Looks great! Yes, 13 mm minimum thickness is overkill.