pumps

XS650 Junkie

My old mufflers had been beat on with a hammer judging by the dents on the ends of each one. After looking at them and trying to cut the reverse parts off the ends, the guts just came out of one. I started looking at mufflers. Money is a little tight for the bike project right now and after reviewing some options I see JCWhitney has some reverse megaphone ones . http://www.jcwhitney.com/chrome-plated-replacement-mufflers/p2006468.jcwx?skuId=142714

They look quite similar to the ones I have seen on a could of sites for more. Anyone try them?

They look quite similar to the ones I have seen on a could of sites for more. Anyone try them?

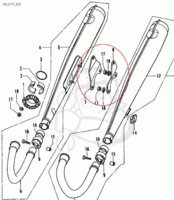

who has tried less than successfully to clamp new mufflers to the external surface of the double tubed OEM headpipes more than once.

who has tried less than successfully to clamp new mufflers to the external surface of the double tubed OEM headpipes more than once.