6fittyspecial

XS650 Enthusiast

Hey guys, yet another build thread. I wanted to catalogue the whole build as I'm doing this for my bro who lives over the other side of Australia.

I have extremely limited space but have about 13 years of experience working on bikes, so I'm hoping one makes up for the other.

Some of this thread might not be super interesting to everyone as I want to share every last detail with my bro, but all your comments and suggestions, if you have any, are more than welcome.

Good to be apart of this community... already seen some awsum builds, ideas and tech tips.

Cheers

Lucas

I have extremely limited space but have about 13 years of experience working on bikes, so I'm hoping one makes up for the other.

Some of this thread might not be super interesting to everyone as I want to share every last detail with my bro, but all your comments and suggestions, if you have any, are more than welcome.

Good to be apart of this community... already seen some awsum builds, ideas and tech tips.

Cheers

Lucas

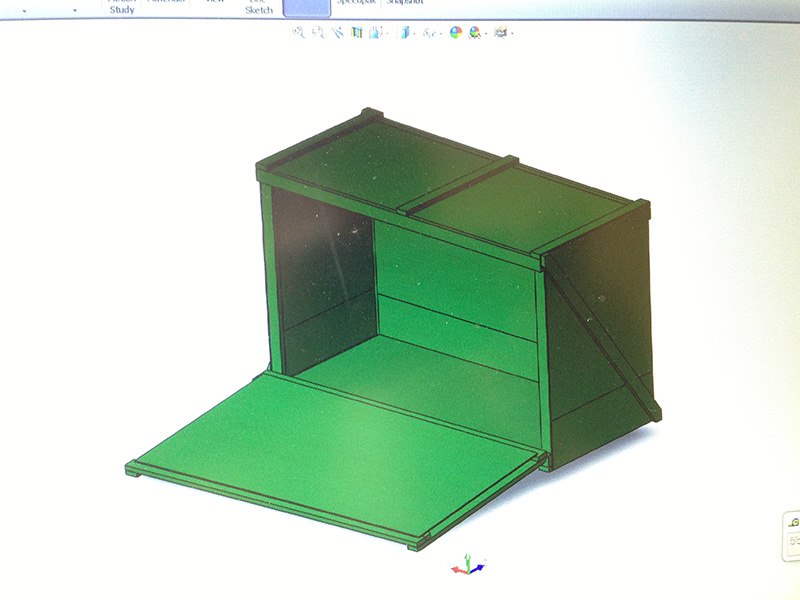

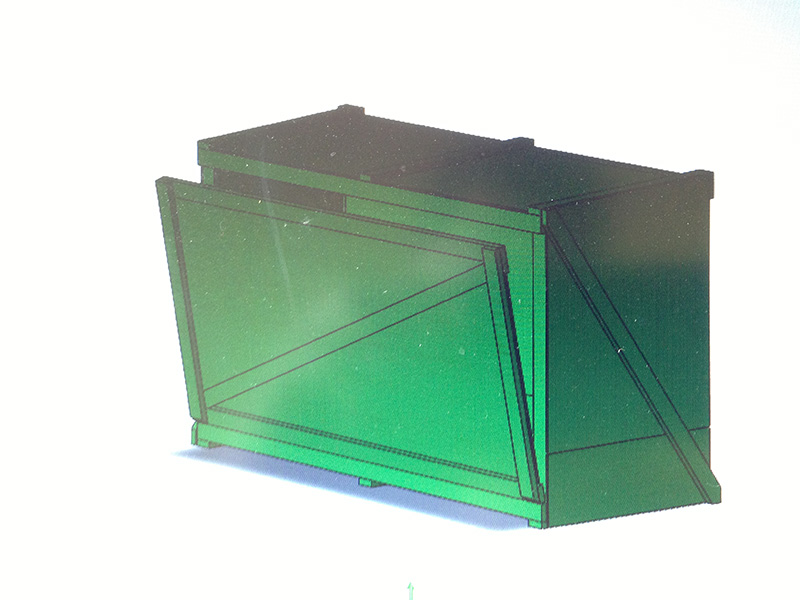

... Works Great!!

... Works Great!!

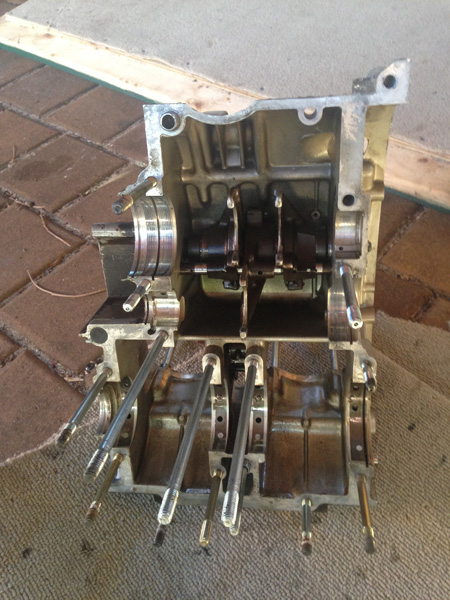

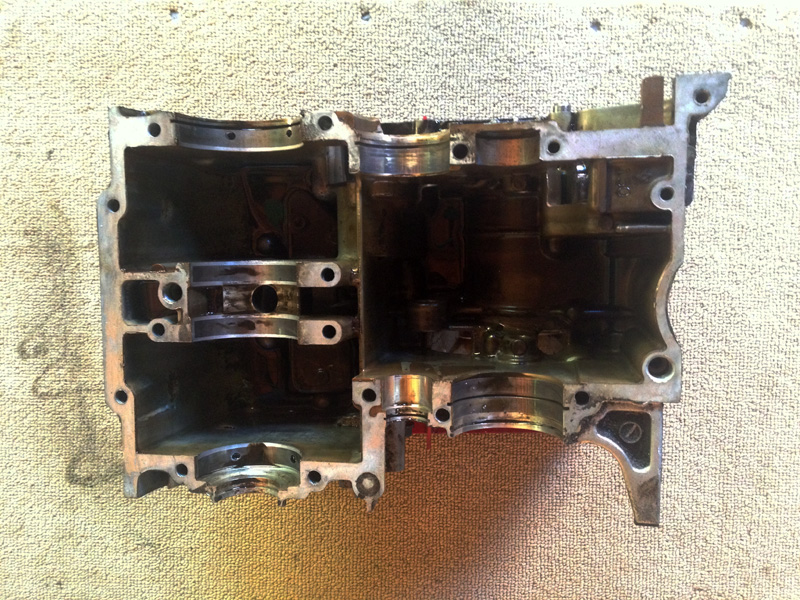

... went away for 2 weeks and came back to find a pile of soaked rags and rusty cyclinders... but I am getting them soda blasted and honed anyway so not really fussed...

... went away for 2 weeks and came back to find a pile of soaked rags and rusty cyclinders... but I am getting them soda blasted and honed anyway so not really fussed...