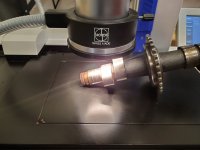

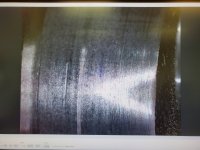

Regarding the seen camshaft galling and rocker arm surface condition, expected standards to me is unclear as to what wear condition is acceptable and for what intended use of the engine.

Being a guy who has always played with a limited budget for motorcycles, I'm seeing a lot of temptation to continue using the shown camshaft and rockers. Agree that those items do show wear but what used engine does not? I've had fun rebuilding a few motorcycle engines when younger and didn't know better to evaluate similar seen wear as "bad". Now, older and wiser (lol). It still would tempt me to polish those cam lobes and rockers on a polishing wheel to see if surface improvement could be made?

But then there is the consideration of protecting the investment in the 750 Big Bore mod which my just deserve being more particular and opening the wallet again.

More example pics and opinions on acceptable wear condition? I find this is interesting and why we are here..

-R

Being a guy who has always played with a limited budget for motorcycles, I'm seeing a lot of temptation to continue using the shown camshaft and rockers. Agree that those items do show wear but what used engine does not? I've had fun rebuilding a few motorcycle engines when younger and didn't know better to evaluate similar seen wear as "bad". Now, older and wiser (lol). It still would tempt me to polish those cam lobes and rockers on a polishing wheel to see if surface improvement could be made?

But then there is the consideration of protecting the investment in the 750 Big Bore mod which my just deserve being more particular and opening the wallet again.

More example pics and opinions on acceptable wear condition? I find this is interesting and why we are here..

-R

) in a nitriding oven. Not sure if that's done any more?

) in a nitriding oven. Not sure if that's done any more?