81 SH Rider

XS650 Member

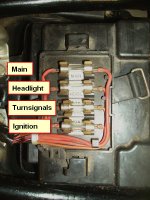

Hello everyone! Thank you all so much for the great information I have found on your site. A special thanks to 650Skull for leading me here. Recently got this 81 XS650 SH knowing it has some maintenance issues, but did know it started, ran and idled ok.... but on battery only till I rode it home, barely. Has a new battery, fuses has been changed to blade automotive. I keep a battery tender on it so it can start, run and I can do tests. After kick starting, the headlight is operating and after warm up, the headlight will just slightly brighten with some revs. At 2000 rpm the battery reads 12.38 volts, at 3500 rpm it reads 12.82. It has passed the slap test to test magnetic field from the rotor. I have installed new alt. brushes from TC Bros (original brushes still had some life in them judging by their length) and have cleaned the outer rotor slip ring. The top alt brush screw reads 11.57 volts to ground. The brown 10 amp fuse in the fuse block reads the same. Bike has 10,081 miles and been garaged its whole life by the looks of it. PO said he put about 500 miles on it in 5 years, but did keep it in his garage. What I have done so far is warm up the engine and then changed the oil with Shell Rotella T4 15-40w changed the sump filter (from Mikes) side filter and gaskets from Boats.net, cleaned and adjusted the chain, cleaned and re-oiled the air filters, replaced the taillights with LED, emptied the gas and added high test with no ethanol. Would really appreciate any help on what to do next. I would like to test the rotor and the stator as well as the reg/rectifier.

1. On the SH model, do you remove the alt brushes and the brush housing to get to the inner rotor slip ring to clean and olm test?

2. On Curleys #3 he says" On the solid state regulator models all you need to do is locate the green wire at the regulator plug and make a jump from it to ground" I think he means to uncouple the harness plug first, am I correct, and use wire with aligator clips?

Thanks guys for your help.

1. On the SH model, do you remove the alt brushes and the brush housing to get to the inner rotor slip ring to clean and olm test?

2. On Curleys #3 he says" On the solid state regulator models all you need to do is locate the green wire at the regulator plug and make a jump from it to ground" I think he means to uncouple the harness plug first, am I correct, and use wire with aligator clips?

Thanks guys for your help.