glennpm

Another Old Biker Nut!

Hi,

I'm putting an Acewell #2853 on and have a Pamco ignition.The Acewell instructions say to wire to the + terminal of the coil but multiple posts here say to wire to the negative. It also seems to keep the RPM form bouncing, that one or two 1MOhm resistors in series may be required.

So should the wire go to the positive or negative coil terminal when using a Pamco?

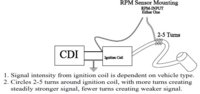

The Acewell diagram shows this wiring:

I'm putting an Acewell #2853 on and have a Pamco ignition.The Acewell instructions say to wire to the + terminal of the coil but multiple posts here say to wire to the negative. It also seems to keep the RPM form bouncing, that one or two 1MOhm resistors in series may be required.

So should the wire go to the positive or negative coil terminal when using a Pamco?

The Acewell diagram shows this wiring:

Attachments

Last edited: