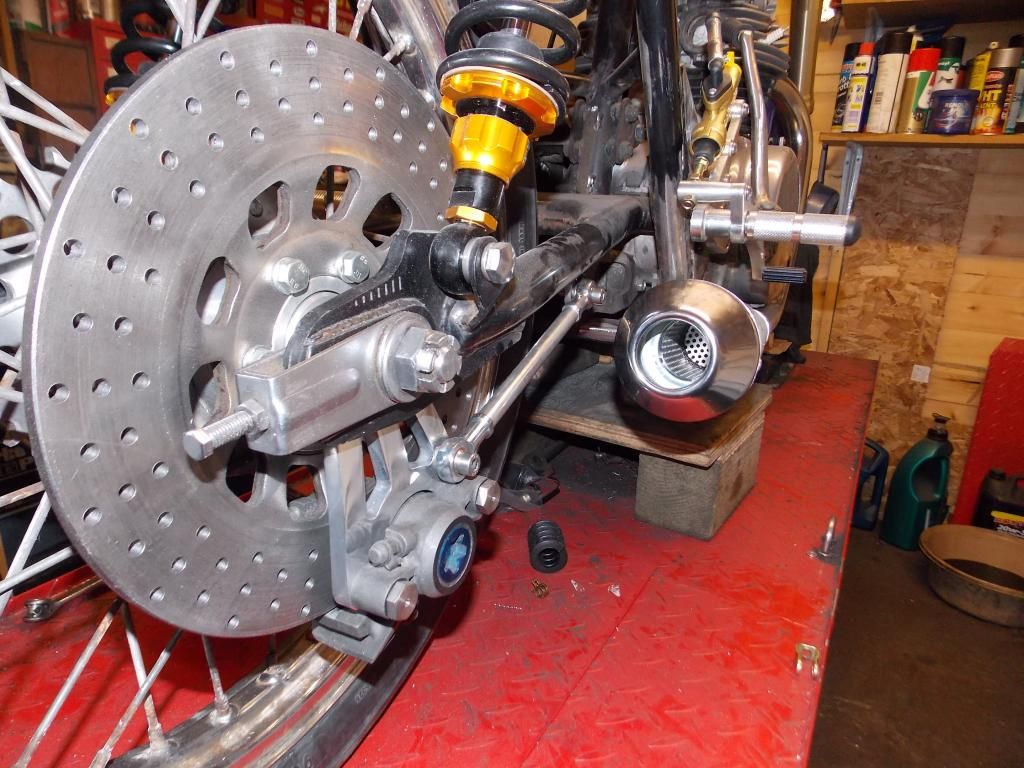

Below is a caliper bracket from Detroit Brothers. Its for a brembo caliper (84mm spacing) on a 11.5" rotor. I just called and they don't make them anymore. I probably won't be able to get a CAD drawing out of them. Anyways, I'm going to draw one up as soon as my caliper comes in. I use Solidworks for design stuff but my machining knowledge is in its beginnings. So......any tips to keep in mind when I do the drawing based on the 3d model I make?

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anybody have machining insight into this bracket I'm about to draw up?

- Thread starter reelop19

- Start date

-

- Tags

- brakes fabricating

jd750ace

Front Toward Enemy

The raised boss reinforces the hole, and is probably fabricated with taking tue place of another part in mind. Tolerances is about the only thing I can mention to keep in mind. I'd water jet most of that after milling that boss. Doyour step files auto generate or does the programmer break them? I only ask because we were having 80k billets cut for some work and the machine shop would not guarantee the work if they did not do the model.

bobberadam

XS650 Enthusiast

- Messages

- 35

- Reaction score

- 0

- Points

- 6

I wouldn't even machine it, you can get that water jetted complete for next to nothing, I don't see any reason to reinforce the axle hole, so should be a simple design and give the water jet place your dxf and move on.

bobberadam

XS650 Enthusiast

- Messages

- 35

- Reaction score

- 0

- Points

- 6

I make all of mine out of 3/16 and have never had a problem.

The caliper bracket w/ axle hole acts as part of your wheel spacing so needs to be a certain thickness. Refer to a stock rear caliper bracket to get that thickness dimension. Then the caliper bracket itself may need to be offset on the axle hole section so the caliper mounts centered on the disc. That's probably why the axle hole section is thicker. Just take a look at an assembled stock rear disc set-up and you'll see what I mean.

bobberadam

XS650 Enthusiast

- Messages

- 35

- Reaction score

- 0

- Points

- 6

Exactly!

I guess If I were designing I'd enlarge the "axle hole" and web around it, fit an axle bushing/spacer through it and weld the bracket to the spacer at the correct offset to align the caliper with the rotor.

I thought about that idea and I might consider doing that myself. However, I'm thinking I might be able to market this idea to the Harley guys or any guys doing a custom using an 11.5" rotor, so I want it to be kind of universal. That way I could just have a bunch cut at once

Paulrxs650

XS650 Enthusiast

Hi,

Heres what I did for mine - no need to machine, it can be done by hand:

Continued working on mounting the rear caliper. In order to do that I had to make a completely new hanger. I started out with some 10mm aluminium plate.

I marked out the dimensions required for the caliper to clear the disc and the relevant hole centres to carry the caliper itself and of course, to receive the axle. To make it look at little better on the eye (and to save weight ) I marked out two areas to be removed in the centre.

) I marked out two areas to be removed in the centre.

After trial fitting, it turned out, as I expected, there was a 3mm offset reqiured, which need a subtle bending of the hanger. The two caliper holes and the stay mount hole were all tapped out to 10mm and 8mm respectively.

Once I was happy with it and the caliper cleared the disc equally either side, it got a buff up on the wheel.

I had some bar ends and some aluminium round bar, so I decided to make the brake stay rod. Fairly simple, I drilled and tapped either end to M8, around 30mm in each end, cut some stainless threaded stud to 45mm and screwed each bar end on. Then a quick once over on the buffing wheel. To attach the other end of the rod to the swing arm, I cut a small bracket from 5mm steel and tapped to M8.

All on and done. I'll weld the bracket up properly when I get the swingarm off.

Heres what I did for mine - no need to machine, it can be done by hand:

Continued working on mounting the rear caliper. In order to do that I had to make a completely new hanger. I started out with some 10mm aluminium plate.

I marked out the dimensions required for the caliper to clear the disc and the relevant hole centres to carry the caliper itself and of course, to receive the axle. To make it look at little better on the eye (and to save weight

After trial fitting, it turned out, as I expected, there was a 3mm offset reqiured, which need a subtle bending of the hanger. The two caliper holes and the stay mount hole were all tapped out to 10mm and 8mm respectively.

Once I was happy with it and the caliper cleared the disc equally either side, it got a buff up on the wheel.

I had some bar ends and some aluminium round bar, so I decided to make the brake stay rod. Fairly simple, I drilled and tapped either end to M8, around 30mm in each end, cut some stainless threaded stud to 45mm and screwed each bar end on. Then a quick once over on the buffing wheel. To attach the other end of the rod to the swing arm, I cut a small bracket from 5mm steel and tapped to M8.

All on and done. I'll weld the bracket up properly when I get the swingarm off.

Great work Paul, thanks for sharing.

Paulrxs650;

+1 with what Gary said! Your rear adapter bracket is about the best looking and fuctional bracket I have ever seen

I had to post a few pics of my adapter brackets......................functional but not real fancy.

+1 with what Gary said! Your rear adapter bracket is about the best looking and fuctional bracket I have ever seen

I had to post a few pics of my adapter brackets......................functional but not real fancy.

Attachments

Paulrxs650

XS650 Enthusiast

Thank you for the comments Gentlemen, very much appreciated!

Paulrxs650

XS650 Enthusiast

Looking very good! Nice job

Similar threads

- Replies

- 5

- Views

- 2K