Hopefully this post does not hijack the thread but adds to understanding why US "Phillips type" screwdrivers "cam-out" when they are applied to JIS cross-point screws....

.......................

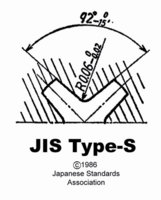

JIS type S Cross-point versus PHILLIPS.................................

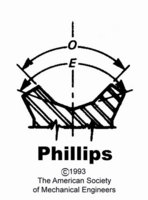

A little known 'troublesome' standard in the US, the Japanese Industrial Standard (JIS for short) is a widespread set of manufacturing standards.You can never tell just where you will encounter products made to them and when conflict of such part design and your tools will arise, it's everywhere. Most everything of Asian origin is going to be compatible with JIS specifications. One such conflict of design frequently arises when our western "Phillips type screwdrivers" are used on JIS cross-point screws & fasteners. Your standard Phillips screwdriver 'hangs up,' and doesn't feel quite right. The Phillips driver won't go into the JIS Screw all the way because the corner radius of the screw is smaller than that of the Phillips screwdriver! This is the primary cause of what we know of and feel as 'cam-out.' It's a result of poor engagement of these incompatible designs. Unnecessary wear and damage inflicted on the fastener, tool or both.

In essence... we here in the US are trying to work with screwdrivers and driver bits that are shaped like the first two figures and so are trying to get them to remove or install screws and bolts that need drivers designed like the next two figures. The rounded double beveled "Phillips" edge into the comparatively sharp single beveled JIS hole just doesn't work right. Cam-out is the predictable and frequent result. Round peg.....square hole! JIS driver or bit into JIS cross-point....hand in glove! Long lasting powerful proper engagement.

Cross-point Screw and Driver Design Characteristics

..................US Phillips..........................................JIS Type S..........................

............. (See Photo Below)..............................(See Photo Below)....................

There are a few places you can get JIS type screwdrivers for proper fit to JIS type fasteners but not many. Moreover, until very recently, none that I've known of from whom to source 1/4" hex drive JIS bits. The Vessel Company of Japan is a source of both high quality tools and industrial bits. JDV Products,Inc. Fair Lawn, NJ is their exclusive North American distributor.

www.vesseltools.com 201-796-1720 If anyone would like I have the specific product call outs of both 1/4" hex drive bits for both slotted and cross point driver bits.....yes folks the JIS standards affect slotted drivers too! Blue

What butterfly seals do you have?

What butterfly seals do you have?

Blue

Blue