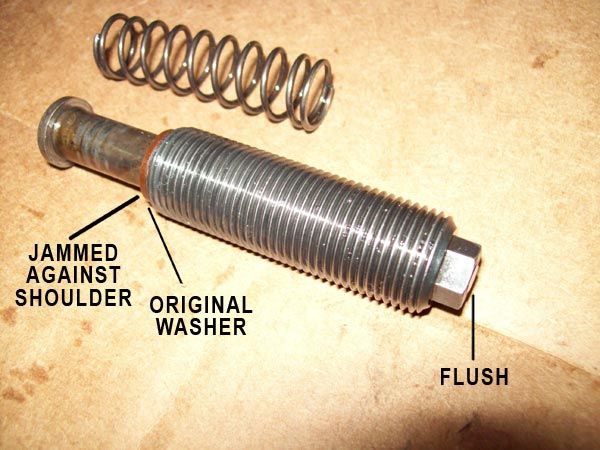

The engine on my 77 XS650D has a tick that I can't locate, so I thought I'd try a rubber washer on the cam chain adjuster. After pulling the adjuster, I noticed that when the adjuster, with the original washer, is jammed up to the shoulder on the rod, the back of the rod is flush with back of the adjuster. Does this look right? There doesn't seem to be any way to tell if the adjuster is too tight.

The last time I adjusted the cam chain I noticed there wasn't very much in and out movement on the adjuster rod, maybe .5 mm. I've got around 10K miles on an OEM cam chain from my local Yarmaha dealer.

The last time I adjusted the cam chain I noticed there wasn't very much in and out movement on the adjuster rod, maybe .5 mm. I've got around 10K miles on an OEM cam chain from my local Yarmaha dealer.