Good day. I am about to do a cam chain and guide replacement as I have found black bits in the side filter screen. I have a simple question. Is it better for me to remove all down to base gasket and build up from there? What I mean is replacing all gaskets from the base on up? My bike is an 1983 with unknown mileage. It has good compression in both cylinders (155 and 150psi). Thanks for the guidance. J-C

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cam chain and guide change

- Thread starter Superjet

- Start date

Sorry maybe I should of added I will be replacing all gaskets, just wondering if I would need to go as far down as the base gasket since I will be close.

Yes, you need to go that far down. The cylinder has to be off to properly mount and center the new guide in the cam chain tunnel. You need to measure from the sides of the chain tunnel to the sides of the guide at both the top and bottom of the cylinder to insure the guide is mounted perfectly straight, vertical, and centered .....

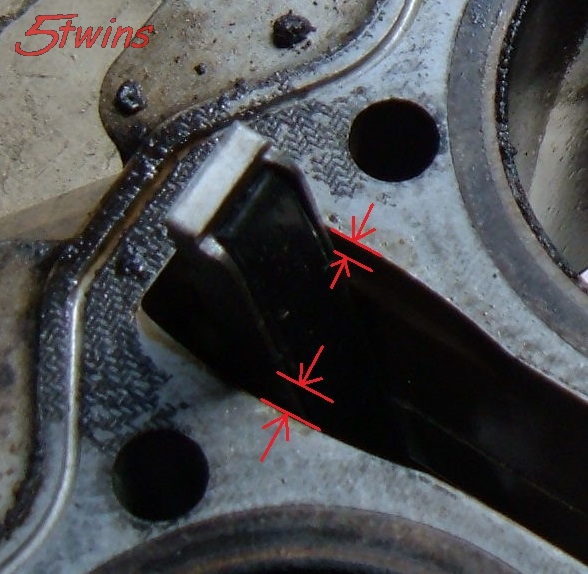

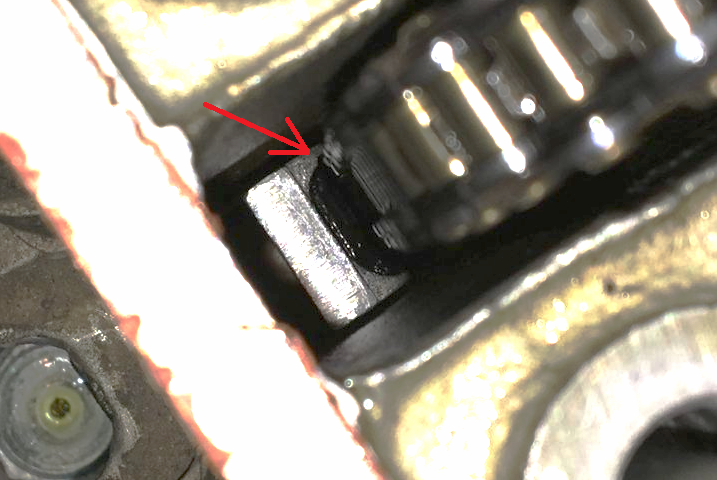

If you don't, you risk this scenario, which another member found recently in his "rebuilt" motor. The chain will rub on and wear into the side of the guide ......

What clued him into the problem was when he drained his oil. He found it full of metal flakes .....

If you don't, you risk this scenario, which another member found recently in his "rebuilt" motor. The chain will rub on and wear into the side of the guide ......

What clued him into the problem was when he drained his oil. He found it full of metal flakes .....

Ok great 5twins...thank you very much. I have watched videos and have read about centering it. I do not have a ring compression tool but have seen some guys simply using a piece or wood or screwdriver to push them in the piston then insert into the cylinders. It is my first engine tear down and will try my best to get it right. Thanks. I have new cam chain, link, guide, bronze sealing washers, seals, gaskets, threebond 1184 (for head cover and head in front of engine in a few spots. Will need to review again your recommendations before assembly.) This is my second XS650 and my first one had all done prior to my ownership. This is someone's project that wasn't finished right.

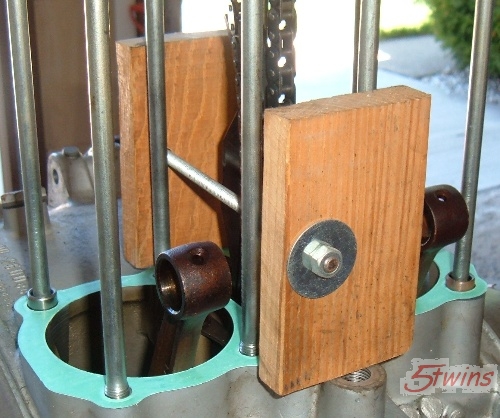

You don't need a ring compressor on these motors. The bottoms of the cylinder sleeves are beveled so it's easy enough to fit the piston and rings into them by just compressing the rings with your fingers as you wiggle/work the piston in. Easiest assembly method is to insert both pistons into the cylinders first with the cylinder block sitting upside down on the bench. Then lower the cylinder/pistons down onto the block and push the piston pins through the rods .....

Work each piston into it's bore one ring at a time. Once in, push the piston in about an inch, so the pin can still stick out the side .....

Work each piston into it's bore one ring at a time. Once in, push the piston in about an inch, so the pin can still stick out the side .....

Thanks! This will help out for sure.

... we use popsicle sticks to press the rings end.. let'n the mass of the pistons to settle in the bore..sometimes a light palm press encourages the process... but never force the issue...

when it comes time to insert the wrist pins and clips... the open case is covered.. that's a learn'n curve you don't need.. also... we always order a extra set of wrist pins clips....had one that " departed the scene " while installing it.. we thought the nice " snap " was the clip snap'n in place... It.. snap'd somewhere.. I'm pretty sure it's in the shop....

when it comes time to insert the wrist pins and clips... the open case is covered.. that's a learn'n curve you don't need.. also... we always order a extra set of wrist pins clips....had one that " departed the scene " while installing it.. we thought the nice " snap " was the clip snap'n in place... It.. snap'd somewhere.. I'm pretty sure it's in the shop....

Thank you guys for the advice. I really want this fix to be good. I don't want to wing it like some jokers do on here. The Yamaha shop manuals tells one story how to do it, but experience and lessons that were learned are what I am looking for here.

5Twins, Like the trick with the block of wood!

Is there a second one on the front side of the cylinders?

Or what does the threaded rod hold on to?

Being a little clumsy and paranoid I always had a clean cloth or paper towel filling the opening to the crankcase before installing cir-clips!

Is there a second one on the front side of the cylinders?

Or what does the threaded rod hold on to?

Being a little clumsy and paranoid I always had a clean cloth or paper towel filling the opening to the crankcase before installing cir-clips!

Yes, there is a 2nd block. This is a little "special tool" I whipped up that I call my "jug blocks". The height was figured out to place the rods about 1/4" below TDC when they are aligned with the piston pins. This allows you to rock the crank back and forth a little, move the rod up or down a bit to align it with the pin. The all-thread rod is offset to one side to clear the cam chain and guide. It is double nutted and permanently attached to one block, just passes through the other. That allows it it be easily separated so it can be removed once the pistons are attached .....

The wood blocks are 5/8"-3/4" thick x 2 5/8-3/4" wide x 4 3/8" tall. The height measurement is the important and critical one, the width and thickness can vary slightly. A 6 3/4" length of 1/4" all-thread holds them together.

The wood blocks are 5/8"-3/4" thick x 2 5/8-3/4" wide x 4 3/8" tall. The height measurement is the important and critical one, the width and thickness can vary slightly. A 6 3/4" length of 1/4" all-thread holds them together.

Hello 5T

I see that there is no gasket cement on that bottom gasket. I have been a little confused on this issue. I believe that you are not supposed to apply Threebond to one of the gaskets but I have never been sure which one. Is this correct?

I see that there is no gasket cement on that bottom gasket. I have been a little confused on this issue. I believe that you are not supposed to apply Threebond to one of the gaskets but I have never been sure which one. Is this correct?

Some of the newer Athena base gaskets come pre-treated with heat activated sealer. I believe this is one of them in my pic. You don't need to treat them with any added sealer. Usually, on an untreated base gasket, I do like to use some sealer, but I don't use Three Bond. I used to use a liquid type of some sort but following a tip here, I've changed to spray-on Copper Coat. I put it on the head gasket too.

Technically, you shouldn't need sealer, the gasket should be enough, but it's common practice to use it on rebuilds. The factory may not have used it but they were dealing with fresh, brand new parts. I used a liquid gasket sealer on my base gasket when I did my topend like 10 years ago and it's never leaked. My head gasket, on the other hand, has given out and is leaking. I just used a few added rings and lines of Three Bond (Yamabond) on that. I wish now I had used more, lol. When I re-do it, I will be spraying the entire gasket with that Copper Coat. Hopefully that will seal better/longer.

Technically, you shouldn't need sealer, the gasket should be enough, but it's common practice to use it on rebuilds. The factory may not have used it but they were dealing with fresh, brand new parts. I used a liquid gasket sealer on my base gasket when I did my topend like 10 years ago and it's never leaked. My head gasket, on the other hand, has given out and is leaking. I just used a few added rings and lines of Three Bond (Yamabond) on that. I wish now I had used more, lol. When I re-do it, I will be spraying the entire gasket with that Copper Coat. Hopefully that will seal better/longer.

Thanks for that info 5T. We have a spray on Copper Gasket cement available here in our auto stores. I assume it is the same thing. I'll spray that on both sides of all gaskets. Does anyone want to buy an unopened tube of Threebond??

bikefreak69

XS650 Enthusiast

I never used any sealer on mine,just made sure it was super clean on the surfaces and 2 heat cycles with retourquing the head bolts.Athena gasket and 6 years now with no leaks from head or base gasket.A prankster kept dropping oil down by the left base of cylinder but never did develop a real leak.Wish I could say the same for the seal kit I bought.Every one of them had to be replaced almost upon start up.Cam seals first,then countershaft seal,then clutch pushrd seal.Crank seal was the only one that held oil.Still is actually.I wont buy that seal kit again.I sourced good seals elsewhere.

Wish I could say the same for the seal kit I bought.Every one of them had to be replaced almost upon start up.Cam seals first,then countershaft seal,then clutch pushrod seal.Crank seal was the only one that held oil.Still is actually.I wont buy that seal kit again.I sourced good seals elsewhere.

Don't keep us in the dark! What is the source for these "good seals"?

My Heritage Special I built an engine for last winter is nice and dry with the exception of either the seal behind the front sprocket or the push rod seal.

I'd like to replace both so I would like to know where to buy these "good seals". As I had purchased the ones in there maybe five years ago I can not be sure where I did buy them.

I'm slowly working on the 1978 and might end up putting the engine that is now in the 1982 Heritage in that bike.

You might have got the same cheap set of seals I did. I eventually replaced most of them with seals from Mike's which ppl seem to agree are among the best. I figured if a seal is the right size it oughta work, but no. My crank seal was the first I noticed leaking. Could not have that getting into the generator. A seal puller similar to this one makes it easy - just tap it through the seal metal and lever it out. piece of sink drain repair pipe is perfect to tap the new crank seal in with,Wish I could say the same for the seal kit I bought.Every one of them had to be replaced almost upon start up.Cam seals first,then countershaft seal,then clutch pushrd seal.Crank seal was the only one that held oil.Still is actually.I wont buy that seal kit again.I sourced good seals elsewhere.

https://www.amazon.com/Lisle-56750-Seal-Puller/dp/B0002SRCKG

Dang 5Twins - that little Jug Block rig is clever. You continue to impress me with your inventiveness and with the care you have taken in documenting your work.

Pete

Pete

Replace the ring that keeps the pin from coming out. You only need to remove one per piston. Mike's ones are good. If you make the opening in the ring line up with the opening in the piston you have maximum contact.

There's no need to remove the pistons from the cylinders unless you need to replace rings, deglaze cylinders, etc. Block up the cylinders evenly just high enough to clear the wristpins, leaving the rings in the cylinders (locking pliers clipped to the studs will get 'er done). Carefully cover the crankcase with rags, and remove the outer wristpin clips. Put a washer small enough to clear the inner clip and big enough to catch the wristpin on a bolt and pass the bolt through the wristpin. Put a socket large enough to clear the wristpin on the free end of the bolt, cover it with a washer, install a nut, and pull the wristpin. If you have to deal with installing rings, it doesn't take more than thumbnails to work them into the cylinder chamfers. 'Course some may run the risk of breaking a nail....