Other tricks to change backwall thrust? Oboy, get to think out of the 'box'.

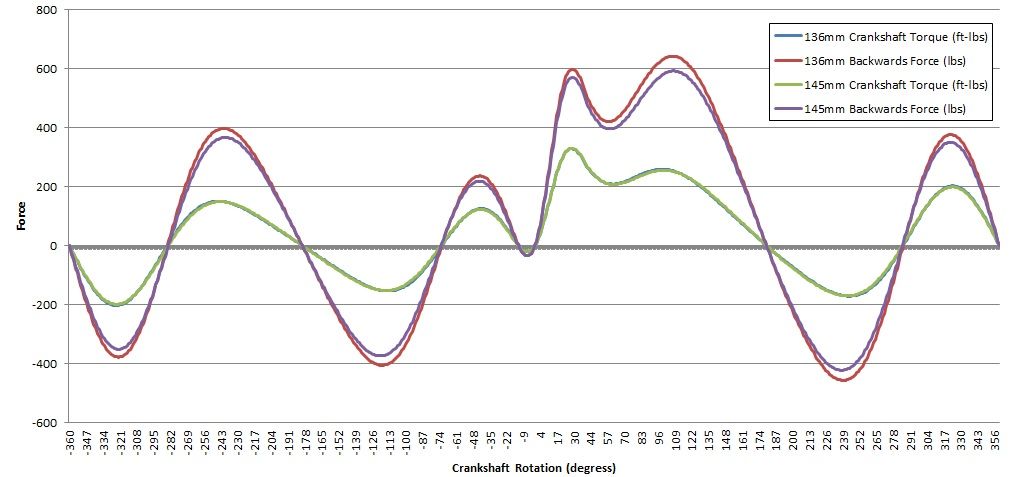

Long rod - If you imagine that the goal is to increase engine block reactive torque, then look at the source - the 3" piston scuffing zone on the cylinder. This zone is a certain distance from crank center, which is the torque arm. By doubling this torque arm, you halve the sliding force of the piston. NOT the 'several feet' mentioned earlier, but you already knew this.

Wristpin offset - Back then, H*nda piston wristpin holes were offset 1mm to the rear (toward intake), as their method to eliminate 'detonation'. Seemed to work. However, when building an engine for dirt work, would sometimes put piston in reverse (after clearancing exhaust 'now intake' valve pocket). The engine demonstrated better mid-range grunt.

Cylinder offset - As an experiment, I installed my factory yam750 cast piston kit with the sleeve offset 1mm to the rear, like the H*nda offset. Bored the offset to the cyl block, the thin factory sleeves cleared into the cases fine. The thing ran like stink, pulled to 9000.

In the early `80s, had the idea for a twin crank, dual rod, single-shared wristpin, single piston engine. Modelled it in an older simulator, showed small mechanical advantage over regular rod engine, but had ZERO sidewall thrust! Fast forward, the Germans introduced a motorcycle with this configuration, maybe you've seen it.

Had an idea for a wristpin stabilizer that would remove ALL sideload from the piston. But to incorporate it would require shorter rod (not a problem here) and a taller piston. The contrivance is rather simple, but would probably blow-up...