kuthe64

XS650 Enthusiast

I have read the tech section on trouble shooting the charging system, and im hung up on the rotor.

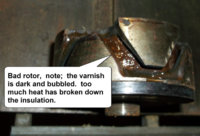

Ive used three different multimeters on the rotor and cannot get a reading at all.(ive cleaned it)

When reving the engine to 3,000 rpm the voltage does not go up at all.

I replaced the brushes.

The slap test was unsuccessful, but to make sure I was doing the slap test correctly I pulled off the stator and turned the key on to test the magnetic field. I put a nail (about two inches long) and it would barley stick to the shaft of the rotor. Im assuming the magnetic field

Stock, 1980 or later, and the headlight doesn't light at all?

should be much stronger than this, does this mean that the rotor is bad?

"You may not have any charging, the headlight is controlled by a relay that is powered directly from the stator, no charging, the relay won't close, no headlight. "

I read this in curlys trouble shooting guide and my headlight does not come on, how would I fix this?

Thank you in advance, and also thank you to everyone that has helped me this far.

81 xs650

Ive used three different multimeters on the rotor and cannot get a reading at all.(ive cleaned it)

When reving the engine to 3,000 rpm the voltage does not go up at all.

I replaced the brushes.

The slap test was unsuccessful, but to make sure I was doing the slap test correctly I pulled off the stator and turned the key on to test the magnetic field. I put a nail (about two inches long) and it would barley stick to the shaft of the rotor. Im assuming the magnetic field

Stock, 1980 or later, and the headlight doesn't light at all?

should be much stronger than this, does this mean that the rotor is bad?

"You may not have any charging, the headlight is controlled by a relay that is powered directly from the stator, no charging, the relay won't close, no headlight. "

I read this in curlys trouble shooting guide and my headlight does not come on, how would I fix this?

Thank you in advance, and also thank you to everyone that has helped me this far.

81 xs650

Last edited: