Steven Simpson

XS650 Addict

hey everyone,

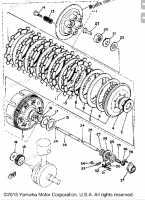

On the last legs of my build., bike fires up and runs nice all electrical is in good standing. But my clutch is just floppy. I thought the obvious and bought a new cable but that didn’t change anything. The pushrod assembly I believe is all correct . When I got the bike it worked ok. But oil cane out the pushrod once and I just decided to continue the build.

I’m getting ready to ride now though and feel a bit stumped as I’ve checked what I think might be the issue.

Thoughts ?

On the last legs of my build., bike fires up and runs nice all electrical is in good standing. But my clutch is just floppy. I thought the obvious and bought a new cable but that didn’t change anything. The pushrod assembly I believe is all correct . When I got the bike it worked ok. But oil cane out the pushrod once and I just decided to continue the build.

I’m getting ready to ride now though and feel a bit stumped as I’ve checked what I think might be the issue.

Thoughts ?