View attachment 261015

Here is the pin removal tool that I made. Easy to make, and works great -- probably just as good as the ones you can buy.

View attachment 261016

The thickness of the hacksaw is about perfect. I looked at a few different blades, and they all seemed to be about he same thickness, close enough that all should work.

Trim the blade to make a 3mm wide probe.

Mark a line 11mm from the end. This will indicate when you have pushed it all the way in. The slot you are entering is fairly deep, and it won't work unless you fully seat the tool.

View attachment 261017

The above instructions apply to a FEMALE blade-type connector. The arrows indicate how thin the release slot is, hence the need for a tool that's as thin as a hacksaw blade. You need a purpose-specific tool to release these pins. A small screwdriver will not work without a lot of frustration and ultimately destroying the nylon connector and damaging the terminal.

I tried my tool on a really lot of different female connectors. The release slot dimensions varied very slightly, and the tool worked well on all of them.

View attachment 261018

The release slot on the MALE side of these connectors varies greatly. Shown above is the tallest slot I came across. A small screwdriver would work here, but it would be easier if you had a third hand. The hacksaw tool works here, but again, it would help if you had a third hand.

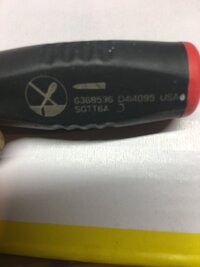

View attachment 261019

I tried to make a couple different tools for the various MALE connectors with their varying release slot heights. The idea is to make a tool with a snug fit, so it stays put when you insert it, and you only need two hands. I used a 3mm stainless spoke, which is the exact width that you need. Then grind to get the height you need for a particular male release slot.