Hey Guys---I'm looking to buy an engine stand and want to know what you think works best---I've been looking at one from Death Wish Kustoms and one from Troy Fabrications to me they both seem good but wanted to get your opinions ----or ant others that you like---thanks tim

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Links are always helpful in your posts.. Are these the two you're talking about?

http://www.ebay.com/itm/New-Yamaha-xs-650-engine-stand-bobber-motor-chopper-/321091126058#ht_121wt_1116

http://www.ebay.com/itm/Yamaha-XS-650-Engine-Rebuild-Stand-Chopper-Boober-Cafe-Custom-/190841452028#ht_330wt_878

I have the one like death wish customs. One thing to watch out for is the clearence under the engine. Often you want to get at the sump, drain, starter, ect.. while it's on the stand. The Troy Fabrications one looks a bit tight there.

http://www.ebay.com/itm/New-Yamaha-xs-650-engine-stand-bobber-motor-chopper-/321091126058#ht_121wt_1116

http://www.ebay.com/itm/Yamaha-XS-650-Engine-Rebuild-Stand-Chopper-Boober-Cafe-Custom-/190841452028#ht_330wt_878

I have the one like death wish customs. One thing to watch out for is the clearence under the engine. Often you want to get at the sump, drain, starter, ect.. while it's on the stand. The Troy Fabrications one looks a bit tight there.

Hey Grepper---Yes those are the ones I've been looking at, I'm to computer challenged to figure out how to do links, so thanks for posting them---I take it you are happy with the Death Wish stand ??

I take it you are happy with the Death Wish stand ??

I'd say so... Like I said, its nice to have access to the underside. The only draw back of any taller stand is the higher center of gravity.

Champco

XS650 Addict

I just built one like the Troy Fab version the other day and it is working out well. Old angle iron and a little bit of time is all it took. You can always make the base wider and increase the length of the legs if you want to access the underneath side of the motor.

Attachments

Last edited:

501Spanky

XS650 Addict

I put my engine on my bench top and stuck a piece of 1X2 scrap wood under the front. To access the bottom, I rolled the engine back ;-)

I'm cheap!

I'm cheap!

deadchef

xsbobblehead

i made one like the troy fab out of an old steel mattress frame. didn't cost me a thing except time. there are some plans in the tech section.

DIRTY DOG

XS650 Guru

t.c.bro's has a nice one for 39.95

jdizon

XS650 Guru

I have a TC Bros. Needed another hand lining up the holes for the mounts when getting the engine on

Champco

XS650 Addict

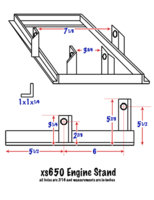

Found one in the tech section. Dimensions worked out perfect

cryingnines

XS650 Enthusiast

I've got the Death Wish Kustoms stand. I'm 100% happy with it

The only reason I have TC Bros. stand is because someone gave it to me. It's a piece of junk and I would never buy one. I have 3 of the homemade ones, two like the Troy Fab, a third with wider front and rear crossbars. I built that one specifically for transporting motors in the back of my truck or Jeep. It's more stable and less prone to tipping over.

Let's see ..... I have a little used stick welder I paid $70 for. Buying 3 stands would cost me close to $150. Looks like my welder has paid for itself ..... twice, lol.

The only good feature on the TC Bros. stand is it comes up the front and allows you to tip the motor on it's "nose" to access the bottom. I already have it pretty much worked out in my head how I'm going to add that feature to some of my stands with a simple bolt-on attachment for the front.

Let's see ..... I have a little used stick welder I paid $70 for. Buying 3 stands would cost me close to $150. Looks like my welder has paid for itself ..... twice, lol.

The only good feature on the TC Bros. stand is it comes up the front and allows you to tip the motor on it's "nose" to access the bottom. I already have it pretty much worked out in my head how I'm going to add that feature to some of my stands with a simple bolt-on attachment for the front.

EvenmoreXS

1981 XS650

Worked for me !

I made it a little taller that the schematic to give a bit more clearance underneath the engine. Also a little wider for better stance. Made it to fit my table.

You can do it !

I made it a little taller that the schematic to give a bit more clearance underneath the engine. Also a little wider for better stance. Made it to fit my table.

You can do it !

Attachments

wherearewe

Rub on Ya Titties

The only reason I have TC Bros. stand is because someone gave it to me. It's a piece of junk and I would never buy one.

Whats wrong with it? Poor quality? Design?

Yes and yes. Even though it's all bolt together and loose, we still had the drive the front bolt through with a hammer - what's up with that? The bolts drop right in on the ones I build. I also don't like the way it attaches to the front motor mount at the base of the cylinders. I remove, install, and move my motors around with two pipe "handles" I made up and one goes there, except it can't with the TC Bros. stand. The handles mount up fine with all those other stands that attach to the center bottom and rear lower engine mounts. We pull the motor, flip it up on one end of the handles, and stick the stand on the bottom. With the TC Bros. stand, the front handle must come off which means rolling the motor around on the ground to get the stand on, and it's a struggle because of the poor fit. That's real good for the alloy cases and the engine fins, lol.

If you like it, buy it. But after using one, I just feel the other style is much, much better.

If you like it, buy it. But after using one, I just feel the other style is much, much better.

shotgunjoe

XS650 Hunter

I have a tc bros stand, and a home made one using the plans available here. The tc bros is flimsy, and doesn't allow you to split the cases. The one I made, is much sturdier, more stable, and allows splitting the cases... I also made mine a little taller to access the bottom.

Make your own, or find a local guy to make you one.

Make your own, or find a local guy to make you one.

angus67

Welder's penetrate deeper!!

2x4. wood work bench so the fins don't snap off. just roll it around.

I do want to make a pipe lifter like you have there 5t.

I do want to make a pipe lifter like you have there 5t.

Brian902

XS650 Junkie

YL82

Perpetual Restorationist

Has anyone bought the one on eBay that rotates?

If so, I'd like to know some of the dimensions. I bit on this one and plan to make a portable stand for it.

http://www.ebay.com/itm/YAMAHA-XS65...Parts_Accessories&hash=item2a372f17e8&vxp=mtr

If so, I'd like to know some of the dimensions. I bit on this one and plan to make a portable stand for it.

http://www.ebay.com/itm/YAMAHA-XS65...Parts_Accessories&hash=item2a372f17e8&vxp=mtr