First post. I have been lurking and learning for about a year and finally decided it was time to get dirty.

Bought a crusty Ebay engine planning on rebuilding it.

its a 75 and seems to be complete. Not much other information given on ebay.

The exterior is completely oxidized and the carbon build up in the exhaust ports is thick and black.

I had planned on spending the time and working through a full overhaul with electrical upgrades.

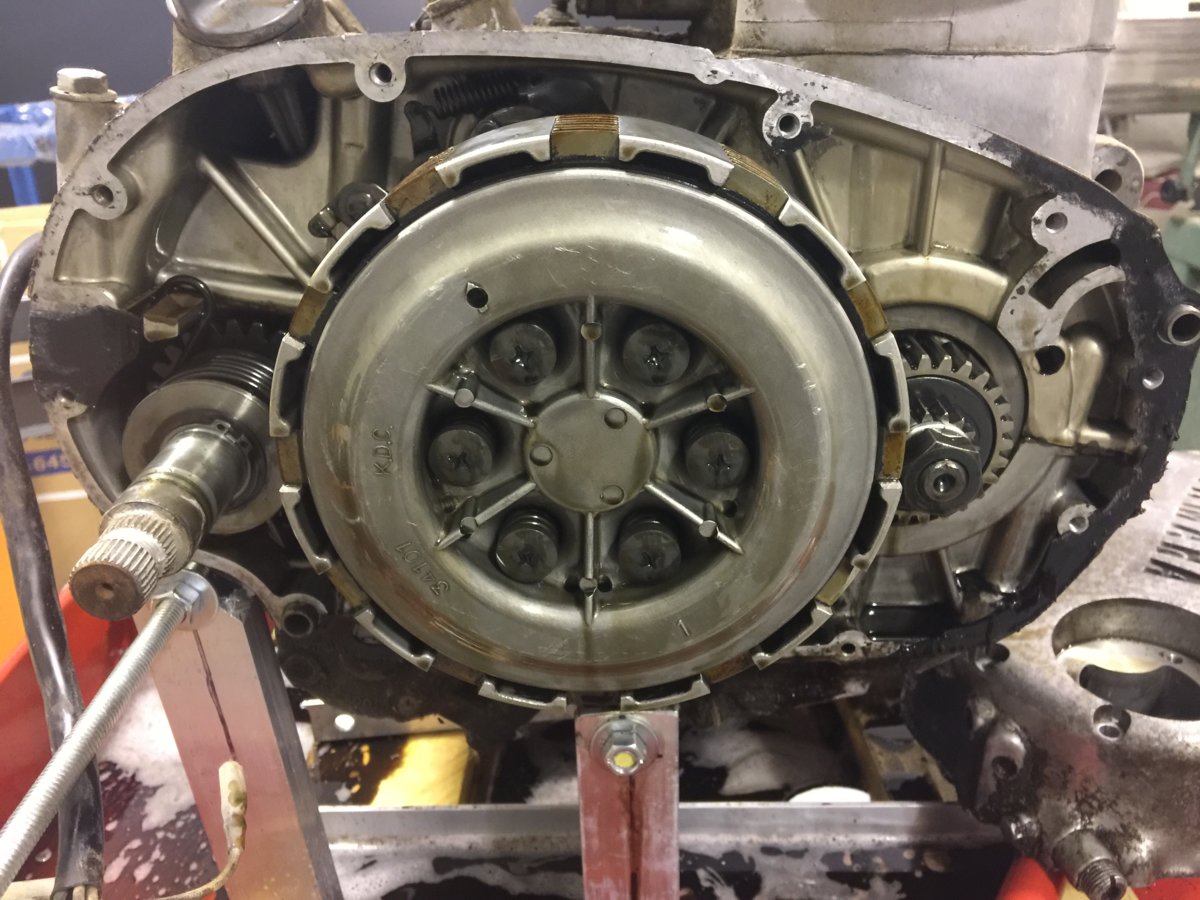

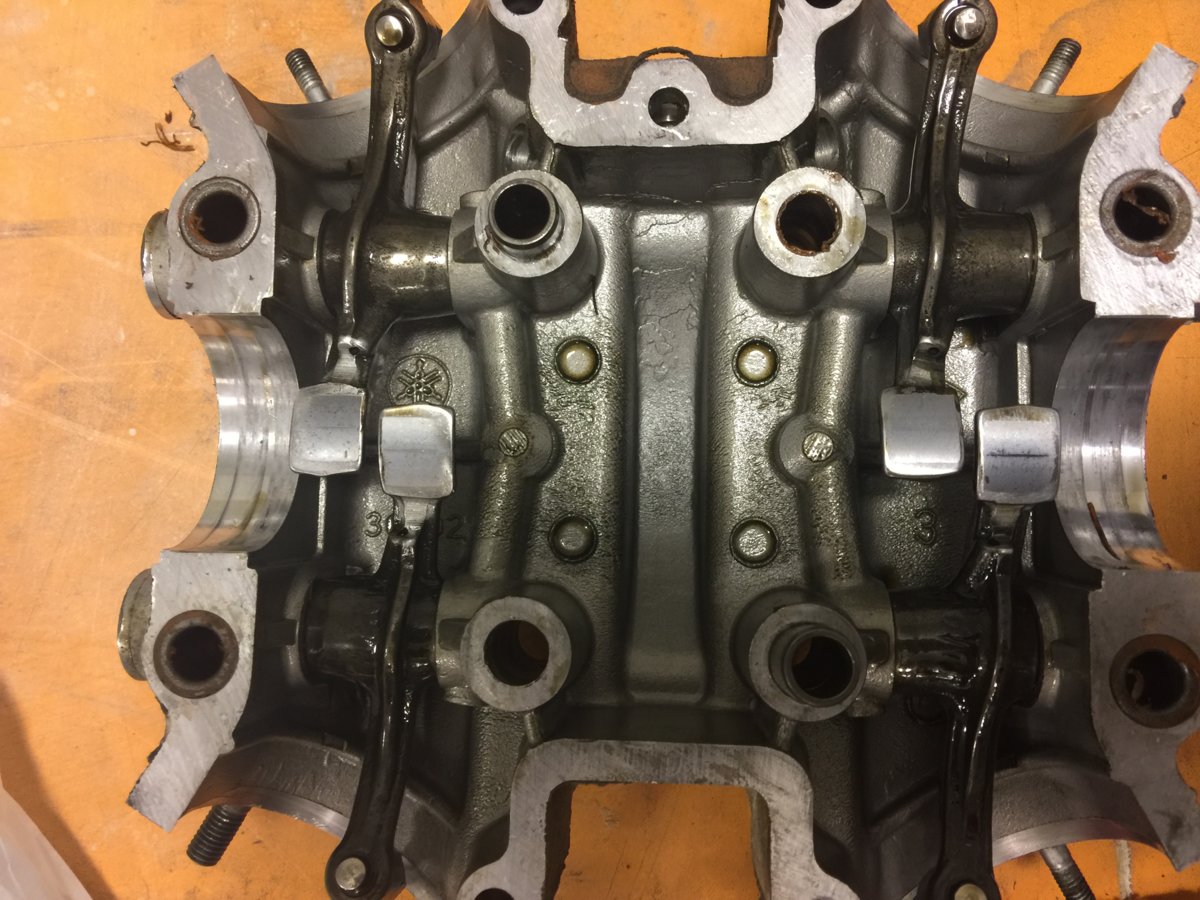

however once I pulled the covers it seems to be in very good condition inside. The oil came out black but no metal in the oil or the upper filter or on the magnet.

Wondering if I should keep it together and clean it up and try to run it?

I can put the valve cover back on and get a compression tester... what other things could I check to help make the decision?

What suggestions do you have for cleaning it up if I keep it together? polish w/ polishing wheel on a die grinder? can I tape it and paint it while it is together?

Any help or suggestions are appreciated.

Bought a crusty Ebay engine planning on rebuilding it.

its a 75 and seems to be complete. Not much other information given on ebay.

The exterior is completely oxidized and the carbon build up in the exhaust ports is thick and black.

I had planned on spending the time and working through a full overhaul with electrical upgrades.

however once I pulled the covers it seems to be in very good condition inside. The oil came out black but no metal in the oil or the upper filter or on the magnet.

Wondering if I should keep it together and clean it up and try to run it?

I can put the valve cover back on and get a compression tester... what other things could I check to help make the decision?

What suggestions do you have for cleaning it up if I keep it together? polish w/ polishing wheel on a die grinder? can I tape it and paint it while it is together?

Any help or suggestions are appreciated.