ippytattoo

Just another grumpy old hack.

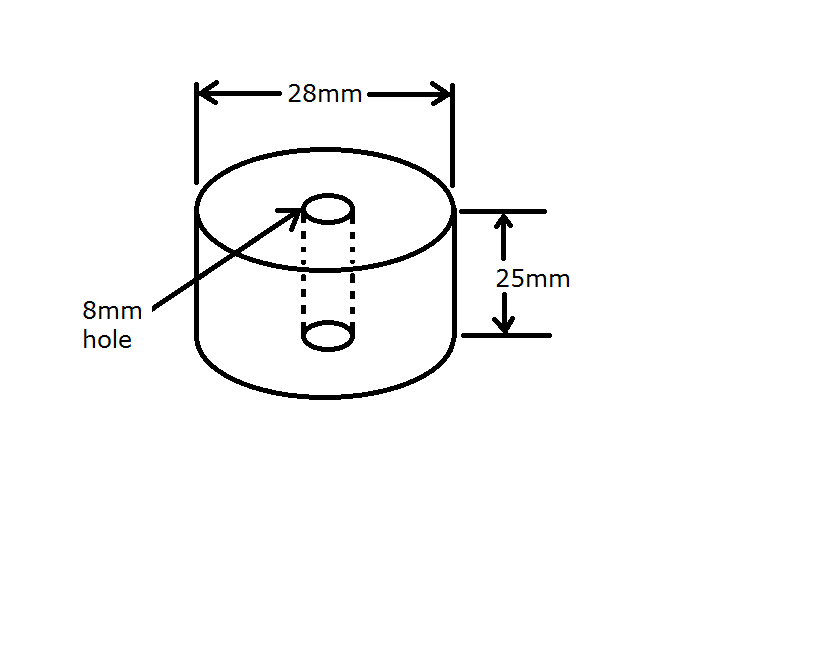

I know this is an odd request but I am in the process of making some tooling to do LH side cover machining so they can accept the Aprilia style hydraulic slave cylinders and I need a piece made for the tooling. I need a slug made that is 28mm O.D. x 8mm I.D. x 25mm long (material is not important, steel or aluminum will be more than adequate).

Like this:

If anyone would be able to help out I would appreciate it.

Clayton

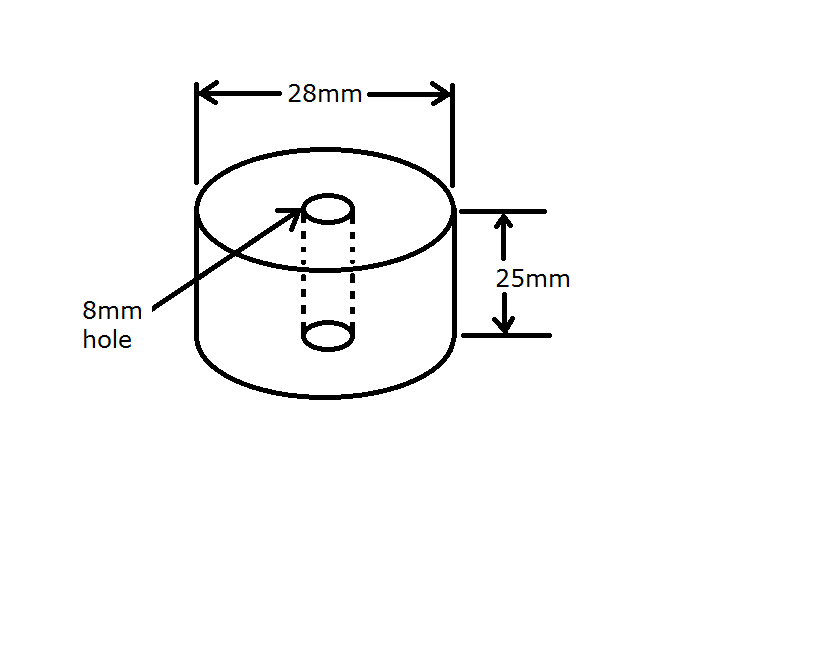

Like this:

If anyone would be able to help out I would appreciate it.

Clayton