Skip

XS 650 Screwturner

I have been chasing a LH Side oil leak recently... thinking that my bike had only been ridden 351 miles over the last 7 years I immediately blamed hardened clutch push rod and main drive seals which replaced with still having a leak.

So today I got the brain wave to do what any other rational thinking person would do in the first place and run the bike with the side cover removed to hopefully see where the oil is coming from....now in my own defense...the oil in the bike now has less than 400 miles on it ...so it is still honey colored and hard to see.....

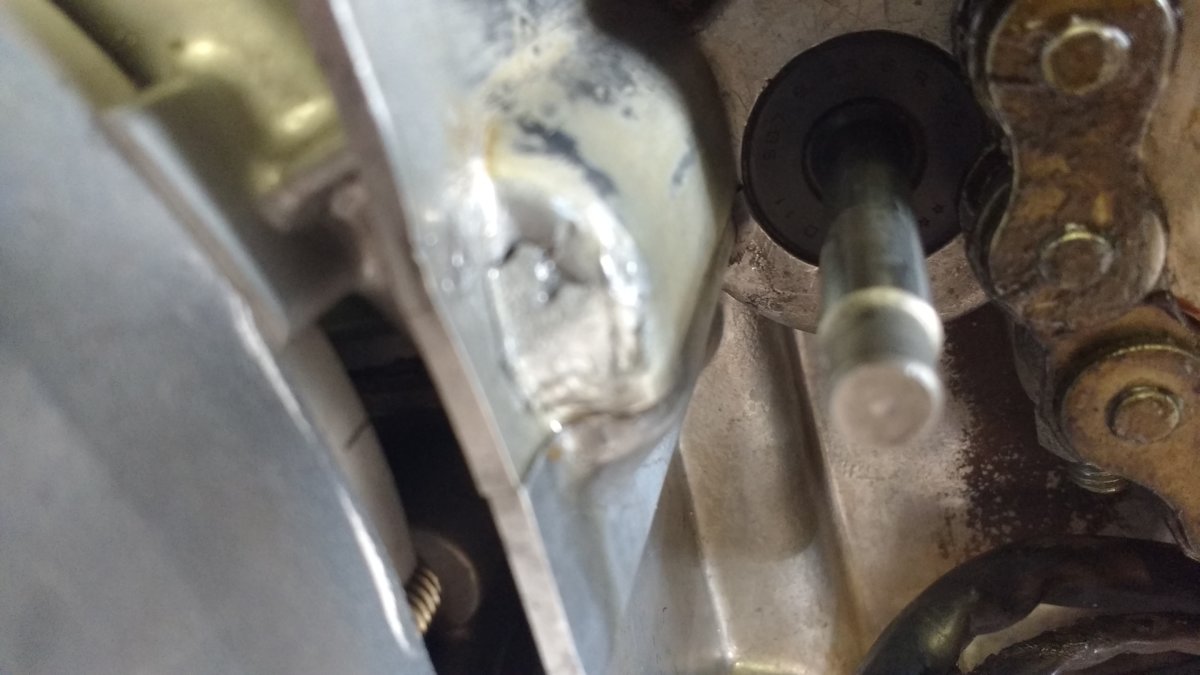

Well what I have found is a imperfection in the upper case casting at the 2' clock position of the stator..about 1/2" above the split in the upper and lower c

ase of the engine which boarders on what I believe. to be a oil return oil galley..

ase of the engine which boarders on what I believe. to be a oil return oil galley..

It had been repaired and I was able to remove the small chunk of repair material that was placed in there who knows how long ago....Have any of you guys seen anything like this before?

So today I got the brain wave to do what any other rational thinking person would do in the first place and run the bike with the side cover removed to hopefully see where the oil is coming from....now in my own defense...the oil in the bike now has less than 400 miles on it ...so it is still honey colored and hard to see.....

Well what I have found is a imperfection in the upper case casting at the 2' clock position of the stator..about 1/2" above the split in the upper and lower c

It had been repaired and I was able to remove the small chunk of repair material that was placed in there who knows how long ago....Have any of you guys seen anything like this before?