I miss more than I'd care to admit to, but as someone who had to take his work out and fly it.... I try not to. Ain't no curbs to pull over to at 8,000 ft.Man you don't miss anything do ya?

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lucille pulls another one on me....

- Thread starter MaxPete

- Start date

-

- Tags

- engine noise

Ah, yes, good point. Man you don't miss anything do ya?

That's why he works on airplanes....you can't just coast off the road and call your Mom or the AAA.

this many...How many threads were still showing?

Madness has a cartridge type oil filter but I loosened the side access cover and drained a bit of oil into a white oil bottle. I could see a bit of metallic in the oil but it wasn't stuffed full. This oil, Valvoline VR1 20-50, has 500 miles on it. Guess I'll ride it to Peoria and back and look again.

BTW it's a 79 2FO motor but no lock nut 5T didn't the 79's have locknuts? spose I could find check the 5t tensioner reference thread.

Last edited:

Have you installed one? How is it working out so far?You mean like this?

That's about what I have on mine; new front guide, substantially used up rear guide, and chain with 60K miles.this many...

Old vs NOS Fleabay find for my '71 motor. Old one is hard & glossy but can easily dig a nail into the NOS item. Far more flexible. Diagonal wear marks on the old guide seem to fall right into Pete's mis-aligned/loose chain theory on the missing edges.

It's installed and it works. Haven't put any miles on it yet.Have you installed one? How is it working out so far?

Well, my TWO complete 1975 timing chain assemblies arrived from Buffalo, NY today, including:

The other thing that arrived today was a snazzy 1979 F-model cam chain tensioner (the one with the coveted locknut). It appears to be complete and functional and it’s even nicely cleaned up.

I am thrilled, I have two sets of timing chain guides and a late model timing chain tensioner - all of which appear to be serviceable.

Stand by for the continuation of the analysis.

It’s not over till I say it’s over.

Pete

- Two timing chains (I likely won’t ever use them because a new chain simply isn’t that expensive);

- Two complete rear guides with the pivots etc. - these look quite serviceable;

- Two front guides (the 256-12231-01-00 part which is the focus of all this heartburn) - and they BOTH look good. There is some light scuffing on them, but a cursory inspection shows no cracks or other significant problems.

The other thing that arrived today was a snazzy 1979 F-model cam chain tensioner (the one with the coveted locknut). It appears to be complete and functional and it’s even nicely cleaned up.

I am thrilled, I have two sets of timing chain guides and a late model timing chain tensioner - all of which appear to be serviceable.

Stand by for the continuation of the analysis.

It’s not over till I say it’s over.

Pete

Last edited:

Pete, the components of the type D and E tensioner assemblies are mostly the same. The only difference is the plunger and the addition of the lock nut. That means you can just swap those items into your original housing, no need to remove and change that to the '79 one you got. I think I would use the '79 adjuster screw too just because the '79 plunger has been running in it.

There were early and late versions of the type E adjuster. The early version continued to use the 60mm long screw and 2mm thick copper damper washer from the type D. The later version switched to a 3mm thick rubber/metal (1mm thicker than the copper washer) damper washer. The screw was shortened 1mm to 59mm to compensate for that. So, measure the length of your adjuster screw. That will tell you which washer to use. But, being from a '79, I'll bet it's the older 60mm screw and copper washer set-up.

There were early and late versions of the type E adjuster. The early version continued to use the 60mm long screw and 2mm thick copper damper washer from the type D. The later version switched to a 3mm thick rubber/metal (1mm thicker than the copper washer) damper washer. The screw was shortened 1mm to 59mm to compensate for that. So, measure the length of your adjuster screw. That will tell you which washer to use. But, being from a '79, I'll bet it's the older 60mm screw and copper washer set-up.

SR guides showed up today Pete.

you ever looked into finding locknuts and rubber washers for older guides?Pete, the components of the type D and E tensioner assemblies are mostly the same. The only difference is the plunger and the addition of the lock nut. That means you can just swap those items into your original housing, no need to remove and change that to the '79 one you got. I think I would use the '79 adjuster screw too just because the '79 plunger has been running in it.

There were early and late versions of the type E adjuster. The early version continued to use the 60mm long screw and 2mm thick copper damper washer from the type D. The later version switched to a 3mm thick rubber/metal (1mm thicker than the copper washer) damper washer. The screw was shortened 1mm to 59mm to compensate for that. So, measure the length of your adjuster screw. That will tell you which washer to use. But, being from a '79, I'll bet it's the older 60mm screw and copper washer set-up.

you ever looked into finding locknuts and rubber washers for older guides?

Locknuts and rubber washers - whaddat?

Lucille only had the hollow nut/bolt thingy that threads into the body of the cylinder barrel and the 6mm shoulder bolts - each of which had copper crush washers on them.

Sorry Pete; my post was a reference to the rear tensioner not the front guide.

Sorry Pete; my post was a reference to the rear tensioner not the front guide.

ahhhhh - had me going there Gary!

Yup - got 'em.

P

Pete, the components of the type D and E tensioner assemblies are mostly the same. The only difference is the plunger and the addition of the lock nut. That means you can just swap those items into your original housing, no need to remove and change that to the '79 one you got. I think I would use the '79 adjuster screw too just because the '79 plunger has been running in it.

There were early and late versions of the type E adjuster. The early version continued to use the 60mm long screw and 2mm thick copper damper washer from the type D. The later version switched to a 3mm thick rubber/metal (1mm thicker than the copper washer) damper washer. The screw was shortened 1mm to 59mm to compensate for that. So, measure the length of your adjuster screw. That will tell you which washer to use. But, being from a '79, I'll bet it's the older 60mm screw and copper washer set-up.

Thanks 5T!

Jim - I'll have a package down to you early next week. No massive hurry at this point I'd say.

Cheers,

p

OK Sports Fans - its time for another installment of....

The Analysis - Chapter 3 - Part - II

Since our last digital vernier extravaganza, I have acquired not one - but two used front timing chain guides. I am told that these are off a 1975 B-model and they came complete with two rear guide assemblies (the one that pivots). I also received two used timing chains.

I will almost certainly never use the old timing chains as these items are readily available and they are not expensive - but they are a fair bit of work to change and so it is false economy to re-use an old one - but if anyone wants one, let me know and they will be "free to a good home" for the price of the ride. You would need to obtain a joining link which will have to riveted.

The "new-to-me" used timing chain guides all look good IMO. There are some marks where the chain has been working, but no large amount of material has been worn off either of the front or rear guides and the ends seem to be intact. There is no sign of cracking of the ends and side "rails" of the front guides (so no black plastic "toothpick" debris seems imminent). In short, they look pretty much like the photos of the guides posted above by Mailman and so, I think that all four guides - and most importantly - the two front guides look to be entirely serviceable. So, I will put them into the hopper as candidates for installation.

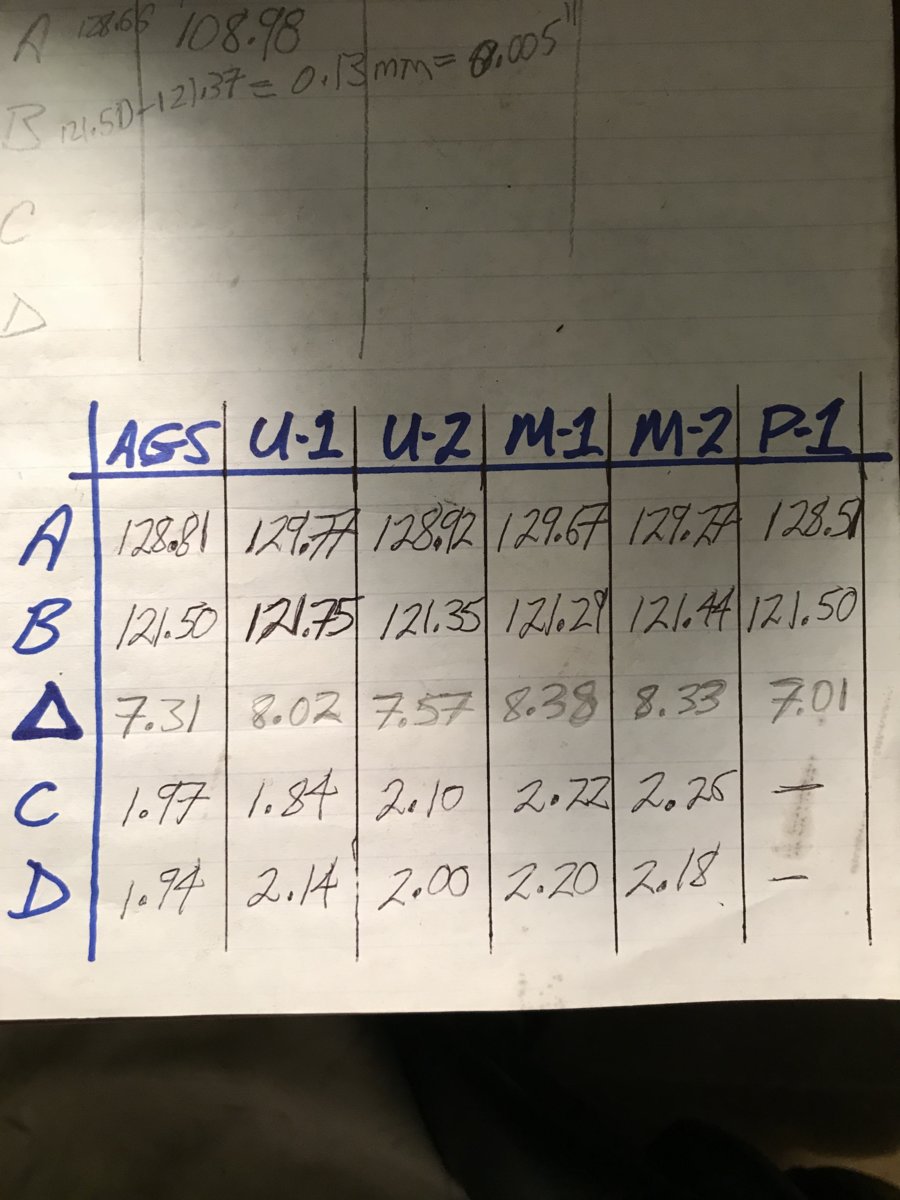

I made a new chart with spaces for the data on all four of my intact guides plus the loaner, AGS, from Lakeview, plus P-1 which is the guide I removed from Lucille a couple of weeks ago. To refresh your memory, my collection now consists of six guides:

DISCUSSION & CONCLUSIONS

The first thing to point out is that all of the data in the chart is in millimeters and 1.0 millimeter is 0.0394" (about 40 thousandths of an inch). Thus, one tenth of a millimeter, 0.1 mm, is 0.004" (four one-thousandths of an inch) and one hundredth of a millimeter, 0.01 mm, is 0.0004" (four ten-thousandths of an inch) - which is an extremely small dimension.

Most over-size pistons and cylinder bores are measured in 0.25 mm increments (about 0.010") and they are made of precision machined metals and not molded plastic and rubber. In fact, I debated giving only one decimal place in the data because of the pliability of the material. You can simply push a little harder on the vernier caliper and change the number by a fair bit - at least on the MikesXS parts which are made of a soft rubbery compound.

As you can see, the data for "new" guides U-1 and U-2 is comparable that for the other three (OEM) guides - and I am surprised to find that no really clear trend emerges (at least not to me). Some of the numbers are higher, some are lower and some are nearly identical - the differences are small.

What this suggests to me is that any of the five guides (AGS, U-1, U-2, M-1 or M-2) would fit and work just fine in an XS650 engine. As in any mechanical assembly, one must consider the function of the part and how it fits together with all of the other parts. In this case, I think the fact that there are so many other components in the assembly - all of which have their own variations - that it is just about impossible to say conclusively that any of these parts is not suitable for service.

The one key differentiator is the softness of the material on the two MikesXS guides. It really is quite different from the material on the OEM guides - and I would guess that it might survive longer in service as a result of not being so brittle - but I could be wrong.

Anyhow, my plan is to take all of the guides to London and see what Terry Wolfe thinks.

A final word: I think that I have beaten this issue to a pulp now. I am likely over-thinking this - but hey, this is a hobby, isnt it?

As always, comments are most welcome!!

Pete

The Analysis - Chapter 3 - Part - II

Since our last digital vernier extravaganza, I have acquired not one - but two used front timing chain guides. I am told that these are off a 1975 B-model and they came complete with two rear guide assemblies (the one that pivots). I also received two used timing chains.

I will almost certainly never use the old timing chains as these items are readily available and they are not expensive - but they are a fair bit of work to change and so it is false economy to re-use an old one - but if anyone wants one, let me know and they will be "free to a good home" for the price of the ride. You would need to obtain a joining link which will have to riveted.

The "new-to-me" used timing chain guides all look good IMO. There are some marks where the chain has been working, but no large amount of material has been worn off either of the front or rear guides and the ends seem to be intact. There is no sign of cracking of the ends and side "rails" of the front guides (so no black plastic "toothpick" debris seems imminent). In short, they look pretty much like the photos of the guides posted above by Mailman and so, I think that all four guides - and most importantly - the two front guides look to be entirely serviceable. So, I will put them into the hopper as candidates for installation.

I made a new chart with spaces for the data on all four of my intact guides plus the loaner, AGS, from Lakeview, plus P-1 which is the guide I removed from Lucille a couple of weeks ago. To refresh your memory, my collection now consists of six guides:

- AGS - this is the loaner from Lakeview. It is out of a (I think) mid-70s XS650B-D and so it has some miles on it, but it looks good with very light scuffing;

- U-1 - this is one of the used 1975 guides that I just received from a eBay purchase. It is an OEM guide in very similar condition to AGS;

- U-2 - a second used 1975 guide - in virtually the same condition as U-1 and AGS.

- M-1 - an aftermarket XS650 Direct / MikesXS part with the slightly misaligned mounting holes and softer rubbery surface versus the very hard plastic surface found on all of the OEM parts;

- M-2 - another MikesXS part similar to M-1.

- P-1 - this is my failed guide from Lucille. It is at the bottom of the heap as this point: it has NO plastic at all and so it consists only of the metal “shoe“.

DISCUSSION & CONCLUSIONS

The first thing to point out is that all of the data in the chart is in millimeters and 1.0 millimeter is 0.0394" (about 40 thousandths of an inch). Thus, one tenth of a millimeter, 0.1 mm, is 0.004" (four one-thousandths of an inch) and one hundredth of a millimeter, 0.01 mm, is 0.0004" (four ten-thousandths of an inch) - which is an extremely small dimension.

Most over-size pistons and cylinder bores are measured in 0.25 mm increments (about 0.010") and they are made of precision machined metals and not molded plastic and rubber. In fact, I debated giving only one decimal place in the data because of the pliability of the material. You can simply push a little harder on the vernier caliper and change the number by a fair bit - at least on the MikesXS parts which are made of a soft rubbery compound.

As you can see, the data for "new" guides U-1 and U-2 is comparable that for the other three (OEM) guides - and I am surprised to find that no really clear trend emerges (at least not to me). Some of the numbers are higher, some are lower and some are nearly identical - the differences are small.

What this suggests to me is that any of the five guides (AGS, U-1, U-2, M-1 or M-2) would fit and work just fine in an XS650 engine. As in any mechanical assembly, one must consider the function of the part and how it fits together with all of the other parts. In this case, I think the fact that there are so many other components in the assembly - all of which have their own variations - that it is just about impossible to say conclusively that any of these parts is not suitable for service.

The one key differentiator is the softness of the material on the two MikesXS guides. It really is quite different from the material on the OEM guides - and I would guess that it might survive longer in service as a result of not being so brittle - but I could be wrong.

Anyhow, my plan is to take all of the guides to London and see what Terry Wolfe thinks.

A final word: I think that I have beaten this issue to a pulp now. I am likely over-thinking this - but hey, this is a hobby, isnt it?

As always, comments are most welcome!!

Pete

Last edited:

Pete, the components of the type D and E tensioner assemblies are mostly the same. The only difference is the plunger and the addition of the lock nut. That means you can just swap those items into your original housing, no need to remove and change that to the '79 one you got. I think I would use the '79 adjuster screw too just because the '79 plunger has been running in it.

There were early and late versions of the type E adjuster. The early version continued to use the 60mm long screw and 2mm thick copper damper washer from the type D. The later version switched to a 3mm thick rubber/metal (1mm thicker than the copper washer) damper washer. The screw was shortened 1mm to 59mm to compensate for that. So, measure the length of your adjuster screw. That will tell you which washer to use. But, being from a '79, I'll bet it's the older 60mm screw and copper washer set-up.

BTW - 5 Twins, you called it perfectly. The tensioner has a 60 mm long screw and a copper washer and it looks very pretty indeed!

Cheers,

Pete

Just got this pic from jrp1.

These came out with the sump filter, rut-roh.

now that's a failed guide!

These came out with the sump filter, rut-roh.

now that's a failed guide!

Last edited:

Just got this pic from jrp1.

These came out with the sump filter, rut-roh.

View attachment 124292

now that's a failed guide!

YIKES - that is even worse than Lucille's guide!

I have delivered my parts to Terry Wolfe and we decided that he would use one of the used 1975 guides. Lakeview came along with me and we met RobinC for lunch after the appointment at Wolfe Worx - fun!

The two used guides are in virtually mint condition and so Terry will take a few minutes and carefully examine both - and pick the best one for the engine.

Some good things have come out of all this - I have learned that:

- the MikesXS aftermarket guides appear to be dimensionally close to the OEM guides;

- the "defects" in the MikesXS guides are not likely significant from a functional standpoint - and in my view, are likely just fine to use in an engine;

- the centring of the guide in the timing chain cavity between the cylinder bores is likely a critical issue as suggested by several of the gurus on the Forum;

- even if the timing chain guide fails - the XS650 engine will still run and it should get you home - likely without lasting harm.

to the Vintage Yamaha Rally event in Stecoah, NC as per the plan.

to the Vintage Yamaha Rally event in Stecoah, NC as per the plan.MANY thanks for all the help, advice and comments along the way - and a special thanks to Lakeview for the loan of the key parts and to RobinC for introducing me to Terry Wolfe of Wolfe Worx in London, ON - truly a world class motorcycle machine shop.

I continue to be a proud member of the best community of motorcycle enthusiasts anywhere.

Pete

Last edited:

Similar threads

- Replies

- 27

- Views

- 4K