Sale alert boys - the seller has slashed the price on those cam bearings I linked to in post #138, down to $5.20 a pair (+ $4 shipping). I bought 4 more (2 pairs), lol. He discounts shipping on multiple items too so the 4 bearings cost me $15.90 total. Yamaha still sells them, they're $19 EACH from Partzilla. Get 4 for less than the price of one from Yamaha, but get 'em while the gettin's good, he only has 8 pairs left now.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lucille pulls another one on me....

- Thread starter MaxPete

- Start date

-

- Tags

- engine noise

Just snagged the last 4.....

Guy must own a warehouse.... he just relisted 10 more at the original 15 bucks a set.

Just snagged the last 4.....

Huh, there was still 6 pair left a little while ago after I grabbed a couple.

Different seller, in Connecticut.....Guy must own a warehouse.... he just relisted 10 more at the original 15 bucks a set.

It's always entertaining when you spew a little venom, Pete !..Well, f@ck ‘em.

.

.

Scott

TIMING CHAIN GUIDE p/n 256-12231-01-00 - Chapter 3: The Analysis

I have read all the stuff about these danged guides and the difficulties with the MikesXS aftermarket parts. I have searched high and low for an NOS example of my own and I’ve come up empty. Judging by the rapidity of the disappearance of these things from all of the usual parts suppliers, I’d say that SOMEbody, SOMEwhere has got a sh!tload of these frickin’ things and they're holding onto them.

Well, f@ck ‘em.

I wanna ride my bike and so, I need a guide and it has to fit and work properly. For that reason, I spent this morning doing a reasonably thorough and objective analysis of my (rapidly growing) collection of timing chain guides. So far, I have four of them and I’ve got two more used OEM guides arriving shortly so I’ll have an even half dozen at my disposal (one of which is a loaner from Lakeview - but it is an actual OEM guide in decent condition).

For the purpose of this analysis, my collection includes:

The key dimension is the distance from the centreline of the timing chain run (as defined by an imaginary line between the centres of the crankshaft and the camshaft) to the surface of the timing chain guide. That timing chain guide surface is where the chain contacts the guide - and not the other parts of the guide body (specifically, not the metal parts of the guide).

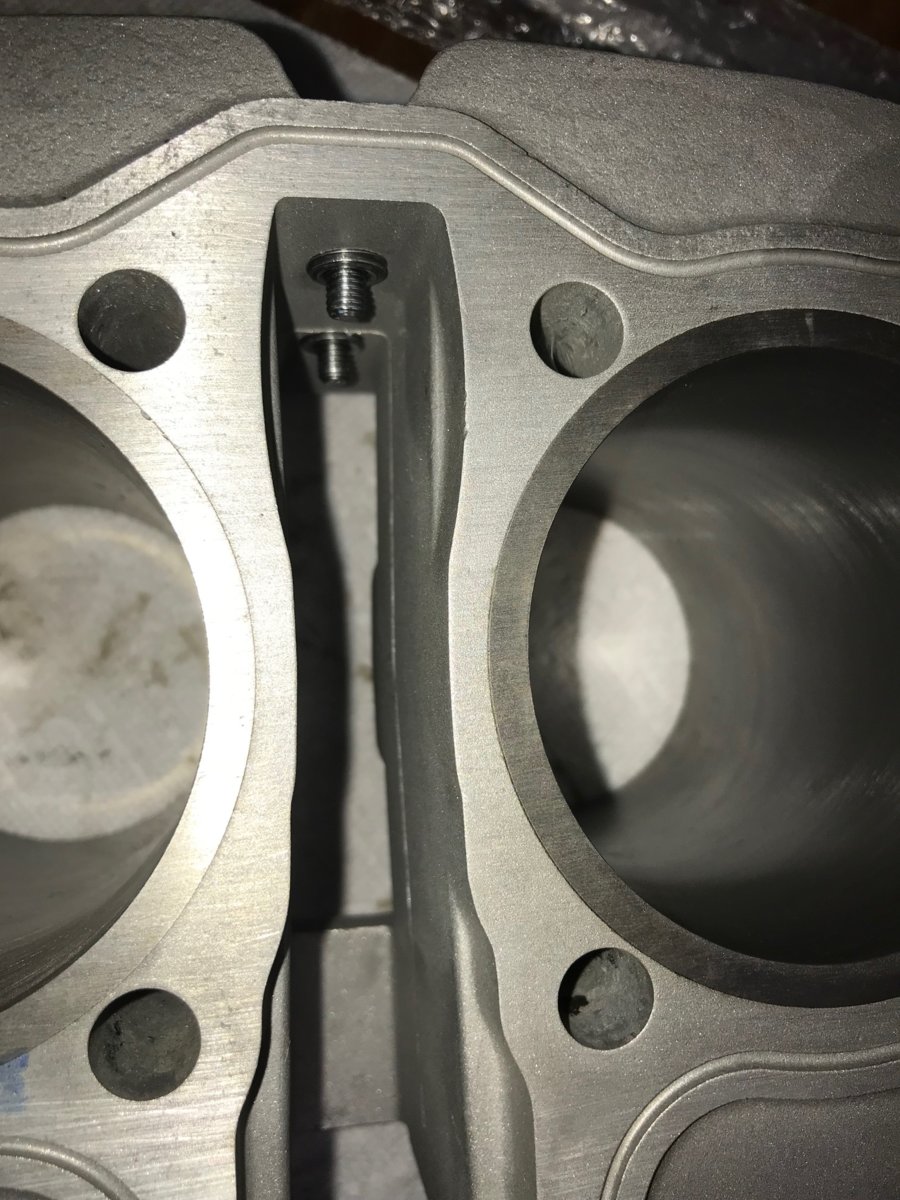

The other key point is that the measurements would best be made from a machined surface and not the rough cast surface of the cylinder barrel body exterior. Every cylinder casting is going to be different but Yamaha actually controlled the position of the guide in a clever way by using those hollow threaded collars AND the shoulder bolts to secure the guide to the inside surface of the timing chain cavity. Thus, the position of the ends of those little threaded collars control the position of the metallic component of the guide (see the photo below and note the little silver cylinders down in the timing chain cavity).

Unfortunately, I cannot measure the actual distance from the line defined by the centrelines of the cam and crank shafts to the guide surface - so I’ll have to use a surrogate measurement from a fixed machined datum on the cylinder barrel body to the guide surface at two points. It’s not ideal, but it’s the best I can do.

To make the measurements, I installed each of the four guides in a cylinder barrel (another loaner from Lakeview) using the stock OEM fasteners, and then I measured from a fixed datum on the mounting surface of the cam chain adjuster mounting pad to the bottom of the U-shaped channel in each guide (see the photo below for an example of how the measurements were made).

I did this measurement at the TOP of the cylinder barrel (the head gasket surface) and at the BOTTOM of the barrel (the base gasket surface).

The first measurement is designated Dimension A and the second is Dimension B in the charts below. The absolute value of each dimension is of interest as is the difference between them because that difference number shows the “tilt” of the guide in the cylinder head assembly.

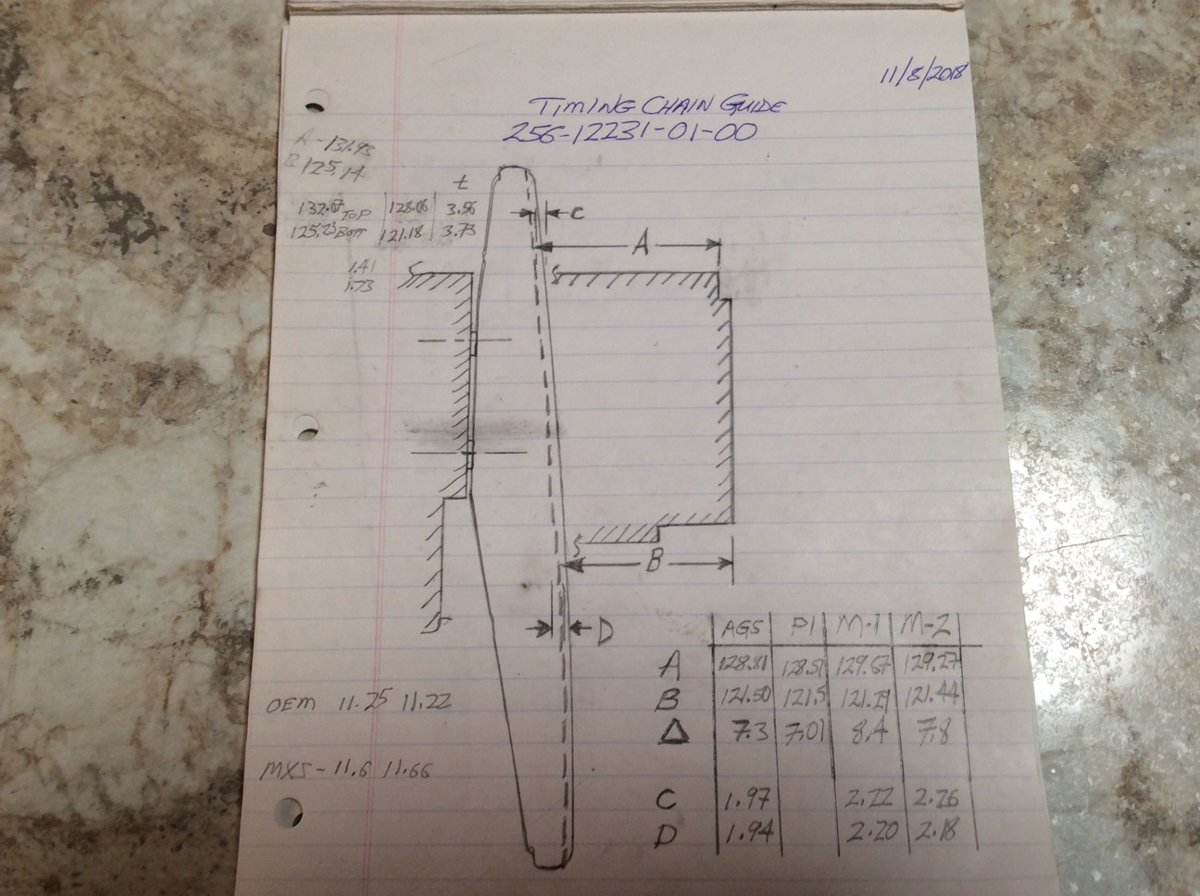

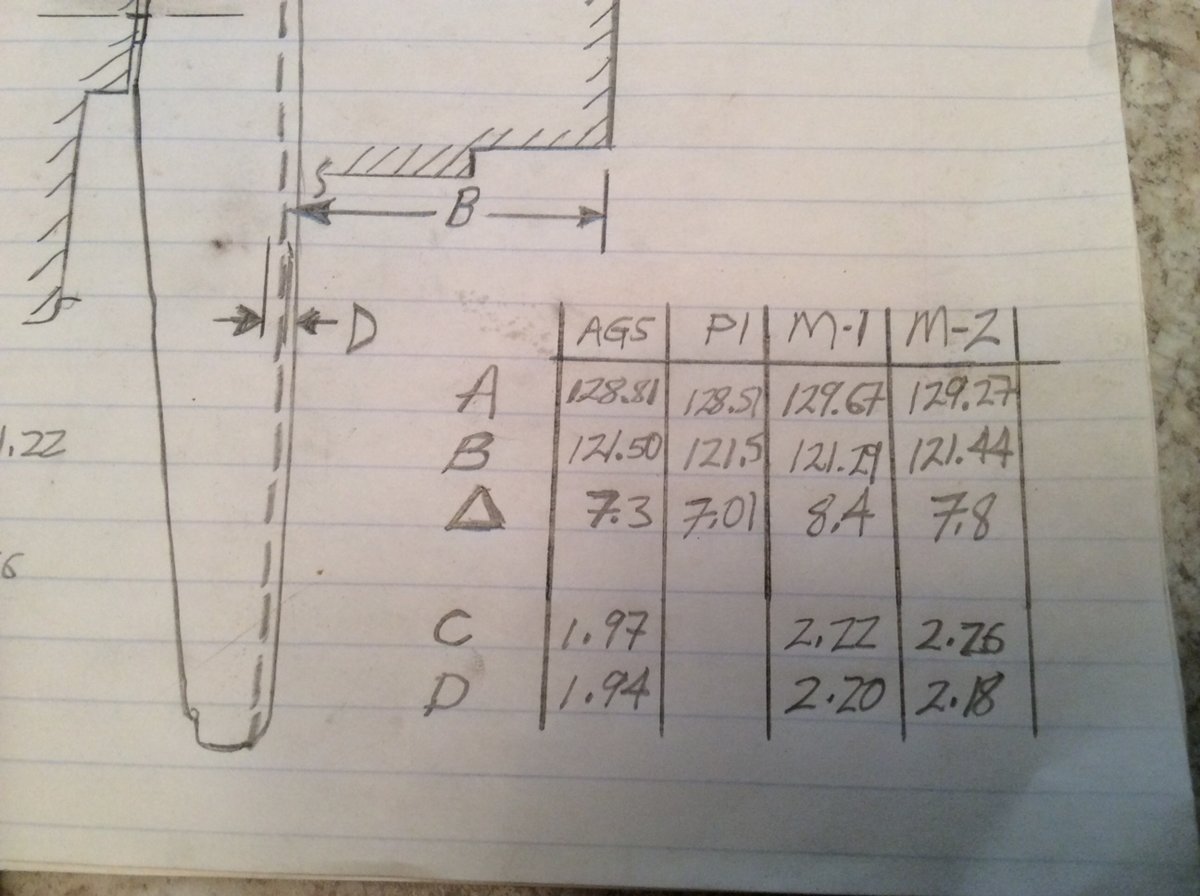

Again, I fully recognize that this analysis is not ideal, but it is the best I can do with what I have. So, here is a sketch of the measurement scheme and a close-up of the data chart.

In the above chart, Dimensions C and D are estimates of the depth of the channel in each timing chain guide. While not particularly important for the function of the part, this data shows something about the consistency of the manufacturing processes of the OEM and the aftermarket suppliers. Actually, MikesXS doesn’t do too badly on this score, IMO.

ANALYSIS:

The data shows that the MikesXS guides protrude about 0.81 mm (about 0.032”) less into the timing chain cavity at the head gasket level (the average of the values of Dimension A) and around 0.13 mm (about 0.005”) at the base gasket level (Dimension B). What happens between those two datums is likely a reasonably linear variation - but I simply don’t know and so your guess is as good as mine. In the chart, the data for the P1 guide (the nude failed guide from Lucille) is estimated from measurements of the metal shoe.

This means that the MikesXS guide will allow the timing chain driven run to be a tiny bit longer than the OEM guide - thus, the cam timing will be slightly retarded from the OEM specs. How this will affect the timing of the camshaft in a quantitative way, I don’t know exactly, but I’d guess that the difference will be small.

In terms of Dimensions C and D - the depth of the “groove” in the guide plastic component:

In the chart this quantity is designated DELTA (the little triangle symbol). The data shows that the MikesXS guides tilt a bit more than the OEM guides - perhaps by around 0.9 mm or about 0.36”. What this means in terms of cam timing....is a matter for conjecture.

DISCUSSION:

While there appear to be trends in the data, the small sample size of OEM and MikesXS parts makes it difficult to give a conclusive answer as to whether the MikesXS parts differ significantly from the OEM parts in ways that would affect how they actually work in an engine.

For this analysis, I only had one intact OEM part (AGS) and two MikesXS parts (the P1 part has no plastic guide surface at all). Also, the AGS part has been in service, while both of the MikesXS parts (M1 and M2) are brand new and also, they are made of a different material, which will have entirely different shrinkage characteristics coming out of the mold.

That raises the issue of production tolerances. Molding plastic and rubber parts is something with which I do have some experience and I can tell you that getting a few thousandths of an inch variation in molded parts is common and nobody can do much about it.

Thus, the variation between the two MikesXS parts and between the two OEM parts seems to be comparable - showing that the production variation between the two manufacturers is not too different.

CONCLUSION:

Well, hmmm.....my gut reaction is that the major differences between the OEM and MikesXS parts can be summarized as follows:

Soooo, I am going to install MikesXS part M2 in Lucille’s engine and I’ll be watching the oil carefully for bits of rubber.

All of this experience with my dear old Lucille has shown that even if the entire plastic component falls off the danged timing chain guide, the tough old XS650 engine will keep going and it will get you there (albeit with a bit of extra noise).

Comments welcome.

Pete

I have read all the stuff about these danged guides and the difficulties with the MikesXS aftermarket parts. I have searched high and low for an NOS example of my own and I’ve come up empty. Judging by the rapidity of the disappearance of these things from all of the usual parts suppliers, I’d say that SOMEbody, SOMEwhere has got a sh!tload of these frickin’ things and they're holding onto them.

Well, f@ck ‘em.

I wanna ride my bike and so, I need a guide and it has to fit and work properly. For that reason, I spent this morning doing a reasonably thorough and objective analysis of my (rapidly growing) collection of timing chain guides. So far, I have four of them and I’ve got two more used OEM guides arriving shortly so I’ll have an even half dozen at my disposal (one of which is a loaner from Lakeview - but it is an actual OEM guide in decent condition).

For the purpose of this analysis, my collection includes:

- AGS - this is the loaner from Lakeview. I will use this one as the benchmark against which I will compare the others. It is out of a (I think) mid-70s XS650B-D and so it has some miles on it, but the plastic surface looks good and has only very light scuffing;

- P1 - this is my failed guide from Lucille. It has NO plastic at all and so it consists solely of the metal “shoe“;

- M1 - this is an aftermarket XS650 Direct / MikesXS part as described earlier. It has the slightly misaligned mounting holes and softer rubbery surface versus the very hard plastic surface found on the OEM parts;

- M2 - another MikesXS part similar to M1.

The key dimension is the distance from the centreline of the timing chain run (as defined by an imaginary line between the centres of the crankshaft and the camshaft) to the surface of the timing chain guide. That timing chain guide surface is where the chain contacts the guide - and not the other parts of the guide body (specifically, not the metal parts of the guide).

The other key point is that the measurements would best be made from a machined surface and not the rough cast surface of the cylinder barrel body exterior. Every cylinder casting is going to be different but Yamaha actually controlled the position of the guide in a clever way by using those hollow threaded collars AND the shoulder bolts to secure the guide to the inside surface of the timing chain cavity. Thus, the position of the ends of those little threaded collars control the position of the metallic component of the guide (see the photo below and note the little silver cylinders down in the timing chain cavity).

Unfortunately, I cannot measure the actual distance from the line defined by the centrelines of the cam and crank shafts to the guide surface - so I’ll have to use a surrogate measurement from a fixed machined datum on the cylinder barrel body to the guide surface at two points. It’s not ideal, but it’s the best I can do.

To make the measurements, I installed each of the four guides in a cylinder barrel (another loaner from Lakeview) using the stock OEM fasteners, and then I measured from a fixed datum on the mounting surface of the cam chain adjuster mounting pad to the bottom of the U-shaped channel in each guide (see the photo below for an example of how the measurements were made).

I did this measurement at the TOP of the cylinder barrel (the head gasket surface) and at the BOTTOM of the barrel (the base gasket surface).

The first measurement is designated Dimension A and the second is Dimension B in the charts below. The absolute value of each dimension is of interest as is the difference between them because that difference number shows the “tilt” of the guide in the cylinder head assembly.

Again, I fully recognize that this analysis is not ideal, but it is the best I can do with what I have. So, here is a sketch of the measurement scheme and a close-up of the data chart.

In the above chart, Dimensions C and D are estimates of the depth of the channel in each timing chain guide. While not particularly important for the function of the part, this data shows something about the consistency of the manufacturing processes of the OEM and the aftermarket suppliers. Actually, MikesXS doesn’t do too badly on this score, IMO.

ANALYSIS:

The data shows that the MikesXS guides protrude about 0.81 mm (about 0.032”) less into the timing chain cavity at the head gasket level (the average of the values of Dimension A) and around 0.13 mm (about 0.005”) at the base gasket level (Dimension B). What happens between those two datums is likely a reasonably linear variation - but I simply don’t know and so your guess is as good as mine. In the chart, the data for the P1 guide (the nude failed guide from Lucille) is estimated from measurements of the metal shoe.

This means that the MikesXS guide will allow the timing chain driven run to be a tiny bit longer than the OEM guide - thus, the cam timing will be slightly retarded from the OEM specs. How this will affect the timing of the camshaft in a quantitative way, I don’t know exactly, but I’d guess that the difference will be small.

In terms of Dimensions C and D - the depth of the “groove” in the guide plastic component:

- the MikeXS guides average 0.28 mm (about 0.007”) deeper than those of the OEM guide.

- I could “estimate” the depth of the groove in the P1 guide, but that would be torturing the data pretty harshly because that guide doesn’t actually have ANY plastic left on it at all.

In the chart this quantity is designated DELTA (the little triangle symbol). The data shows that the MikesXS guides tilt a bit more than the OEM guides - perhaps by around 0.9 mm or about 0.36”. What this means in terms of cam timing....is a matter for conjecture.

DISCUSSION:

While there appear to be trends in the data, the small sample size of OEM and MikesXS parts makes it difficult to give a conclusive answer as to whether the MikesXS parts differ significantly from the OEM parts in ways that would affect how they actually work in an engine.

For this analysis, I only had one intact OEM part (AGS) and two MikesXS parts (the P1 part has no plastic guide surface at all). Also, the AGS part has been in service, while both of the MikesXS parts (M1 and M2) are brand new and also, they are made of a different material, which will have entirely different shrinkage characteristics coming out of the mold.

That raises the issue of production tolerances. Molding plastic and rubber parts is something with which I do have some experience and I can tell you that getting a few thousandths of an inch variation in molded parts is common and nobody can do much about it.

Thus, the variation between the two MikesXS parts and between the two OEM parts seems to be comparable - showing that the production variation between the two manufacturers is not too different.

CONCLUSION:

Well, hmmm.....my gut reaction is that the major differences between the OEM and MikesXS parts can be summarized as follows:

- The dimensional differences are detectable - but likely not sufficient to impair the functionality of the MikesXS parts.

- The hole alignment differences are also detectable, but can be mitigated by applying a dab of sealant under the crush washers - and the mounting of the MikesXS guides in the cylinder barrel is not affected in a material way;

- The one major difference is the softness of the plastic / rubber moulded component and in my view, it cannot be concluded that this is a disadvantage of the MikesXS guide.

Soooo, I am going to install MikesXS part M2 in Lucille’s engine and I’ll be watching the oil carefully for bits of rubber.

All of this experience with my dear old Lucille has shown that even if the entire plastic component falls off the danged timing chain guide, the tough old XS650 engine will keep going and it will get you there (albeit with a bit of extra noise).

Comments welcome.

Pete

Last edited:

Nice documentation and analysis of the parts! Are there any cases of failure of the Mike's XS (XS 650 direct) guide other than what was noted up above? I am skeptical about installing a 30 to 40 year old part but if it only has an effect when in contact with the mecanics of the engine and lubrication, it should last 30 to 40 years once installed? Anyone ever install a NOS guide and has inspected it after years of use? Cool early morning sitting and sipping coffee! Thanks Maxpete got my brain awake before work lol!!

MaxPete I'll add some recent history for your story. About 7 years ago sourcing this part became almost impossible. Prices went from 35-40 per, to 70 them to $100 if you could find them. Builders were begging, pleading to find them to finish builds.

My solution was to get on the phone and jus talk to folks. Asking for the names of old established shops in their area. Then I gave that shop a call and tried to speak with someone over the age of 50, That could find parts without giving up on what the computer said. I ended finding 3 OEM sitting on shelves.

Maybe this would help your search. If you could do a time search of the forum about that time you will find a double handfull of threads about replacing the liner.

My solution was to get on the phone and jus talk to folks. Asking for the names of old established shops in their area. Then I gave that shop a call and tried to speak with someone over the age of 50, That could find parts without giving up on what the computer said. I ended finding 3 OEM sitting on shelves.

Maybe this would help your search. If you could do a time search of the forum about that time you will find a double handfull of threads about replacing the liner.

Great write up Pete. Love your drawing skills! Thought only 2M was at that level around here....

Tossing a stick in the fire. What about a brass rivet or 2 to hold oem rubber to the guide both failed and "yet to fail" old OEM guides?

What WER sez about beating the bush for NOS guides! Unfortunately you are unlikely to find anyone on the forum willing to give up an OEM guide, by definition we are all in the same boat down the road.

I'm kind of 'spicious of Madness, had to run the adjuster in pretty far on a recent chain check. Making me think of what bike to run down to Peoria, gonna pop off the side screen cover and try to "read the tea leaves" today.

Rub WS2 into any guide rubber going in a motor? Pete are you considering chain sanding? Honestly that scares me, going to get abrasive residue into the rollers, can't be avoided......

Tossing a stick in the fire. What about a brass rivet or 2 to hold oem rubber to the guide both failed and "yet to fail" old OEM guides?

What WER sez about beating the bush for NOS guides! Unfortunately you are unlikely to find anyone on the forum willing to give up an OEM guide, by definition we are all in the same boat down the road.

I'm kind of 'spicious of Madness, had to run the adjuster in pretty far on a recent chain check. Making me think of what bike to run down to Peoria, gonna pop off the side screen cover and try to "read the tea leaves" today.

Rub WS2 into any guide rubber going in a motor? Pete are you considering chain sanding? Honestly that scares me, going to get abrasive residue into the rollers, can't be avoided......

Last edited:

How many threads were still showing?had to run the adjuster in pretty far on a recent chain check.

I like the drawing too, esp. that old blueprint style of lettering. Many hours spent with Koh-i-noors back in the day, eh?

The difference in hardness of the rubbery material, is that compared with an unused NOS guide?

The difference in hardness of the rubbery material, is that compared with an unused NOS guide?

Great write up Pete. Love your drawing skills! Thought only 2M was at that level around here....

Tossing a stick in the fire. What about a brass rivet or 2 to hold oem rubber to the guide both failed and "yet to fail" old OEM guides?

What WER sez about beating the bush for NOS guides! Unfortunately you are unlikely to find anyone on the forum willing to give up an OEM guide, by definition we are all in the same boat down the road.

I'm kind of 'spicious of Madness, had to run the adjuster in pretty far on a recent chain check. Making me think of what bike to run down to Peoria, gonna pop off the side screen cover and try to "read the tea leaves" today.

Rub WS2 into any guide rubber going in a motor? Pete are you considering chain sanding? Honestly that scares me, going to get abrasive residue into the rollers, can't be avoided......

Eeeeeyahhh - chain sanding sounds like an attractive idea initially, but all of that metal swarf floating around.....hmmmm....yuk.

The failure mode of the XS650 chain guide seems to take one or more of three definite patterns (and I MAY be wrong as I've only seen a few pictures and my own naked guide from Lucille). As I see it, there are three distinct types of failure and depending on how "lucky" you are and how long you let things go, you may see one, two or all three of them:

- some of the flat surface wears off as tiny particles and winds up in the oil and then in the oil filter / strainer;

- the raised edges of the "plastic rail" tend to flake off in fairly large pieces and land in the sump (see the earlier photos of the "toothpick" shaped bits that I found in Lucille's sump;

- the entire plastic "slab" simply falls right off the metal shoe portion of the guide and flops down into the bowels of the engine.

- the particles abrade off the flat portion of the plastic guide due to a shortage of lubricant (engine oil) AND / OR the oil is too dirty to be a decent lube;

- the raised edges flake off because the chain is run loose and it flaps around, beating up those edges at the sides of the guide AND / OR the guide is not centred as wisely advocated by 5Twins and others;

- the entire plastic slab falls off due to age and exposure to too much heat - the glue simply gives up. NOTE: heat is another symptom of oil shortage.

The last causal factor - heat & age - which lead to failure of the bond between the plastic and metal components is partially a maintenance item (once again, change the damned engine oil) but it is also an unavoidable consequence of the fact that our bikes are at least 34 and as much as 48 years old.

Stuff is gonna go and 1970's era adhesives simply were not as good as the stuff we have today. Witness the Aloha Airlines Boeing 737 that lost the upper part of its fuselage. The cause was metal fatigue around some rivet holes and a contributing factor was the failure of aluminium-to-aluminium bonding (i.e. glue) of the fuselage skins - and note that bonding a piece of hard plastic to a piece of metal is much less likely to work well than bonding two similar materials as Boeing was doing on that airliner.

Frankly - if you stare at the chain and the guide, it becomes clear that the only part of the chain that is supposed to touch the XS650 guide are the edges of the side plates of the timing chain. As you point out Gary, the edges of the side plates could be sharp and sort of "saw" at the plastic surface of the guide and potentially damage it, but I'd guess that if there is sufficient clean oil in the engine, that sawing action should be fairly minimal. The age thing....is simply not preventable.

Now - the alternative is the SR500 timing chain guide design in which the chain rollers ride on a raised central "rail" instead of the chain side plates as in the XS650 guide design (see the photo of an SR500 guide below). Unlike the side plates of a chain, the rollers present a smooth finished surface to the plastic guide material and are very unlikely to "saw" at the plastic and abrade it. The SR500 guide is, in my view hugely superior to the XS650 guide for that reason - regardless of what material is used for the plastic component.

Anyhow - for now, I have what I have and so I'll be changing my oil frequently, checking it daily, checking the timing chain tension often and I'll be buying another gasket set for when I need to get in and change that danged guide again.

As always, comments welcome!

Cheers,

Pete

Last edited:

I like the drawing too, esp. that old blueprint style of lettering. Many hours spent with Koh-i-noors back in the day, eh?

The difference in hardness of the rubbery material, is that compared with an unused NOS guide?

Thanks for the kind words - it has been a while since I did any manual drafting but I truly enjoy it a lot. Koh-i-noors - yup!!

I don't think I have run across major durability issues with the MikesXS guides - but I may have missed something. My guess is that centring it carefully on installation plus the on-going oil and chain tension maintenance should help a lot on that score.

As for the hardness, I don't have any real data except the "fingernail digging-in" test I did.

The used OEM guide is extremely hard plastic - NO WAY can you dig in a fingernail but the MikesXS is noticeably soft and a fingernail can easily make an impression - from which the guide recovers quickly - so that stuff seems to be pretty durable.

I have never actually seen a new OEM guide but I doubt it is much different than the used one that I have on loan from Lakeview. As noted, I have two more used ones coming shortly so I'll have somewhat more data soon.

Last edited:

Pete, my memory ain't what it used to be.... but I'm thinin' the OEM guides rubber is more the consistency of Mikes guide than plastic. Maybe @robinc or @Mailman can chime in here... as they both have recent experience handling them. I think the "hard plastic" is an age related issue.The used OEM guide is extremely hard plastic - NO WAY can you dig in a fingernail but the MikesXS is noticeably soft and a fingernail can easily make an impression - from which the guide recovers quickly - so that stuff seems to be pretty durable.

While I'm here..... I did sand down the edges of my chain.... followed by multiple cycles of soaking in the Stoddard tank and blowing clean with shop air. I'm confident it's clean.

While I'm here..... I did sand down the edges of my chain.... followed by multiple cycles of soaking in the Stoddard tank and blowing clean with shop air. I'm confident it's clean.

Hmmmmm....well, OK then - how did you sand it it Jim?

Red then blue Rolok disks.

Similar threads

- Replies

- 27

- Views

- 4K