-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mailman’s XS2 a full on restoration

- Thread starter Mailman

- Start date

Bob, like gggGary alluded, the unlubed un-broken-in points followers have significant drag.

- Remove the points plate, recheck advance rod motion.

- With the points plate removed, it's much easier to install the points wiring.

- Have the wiring lugs atop of the points springs.

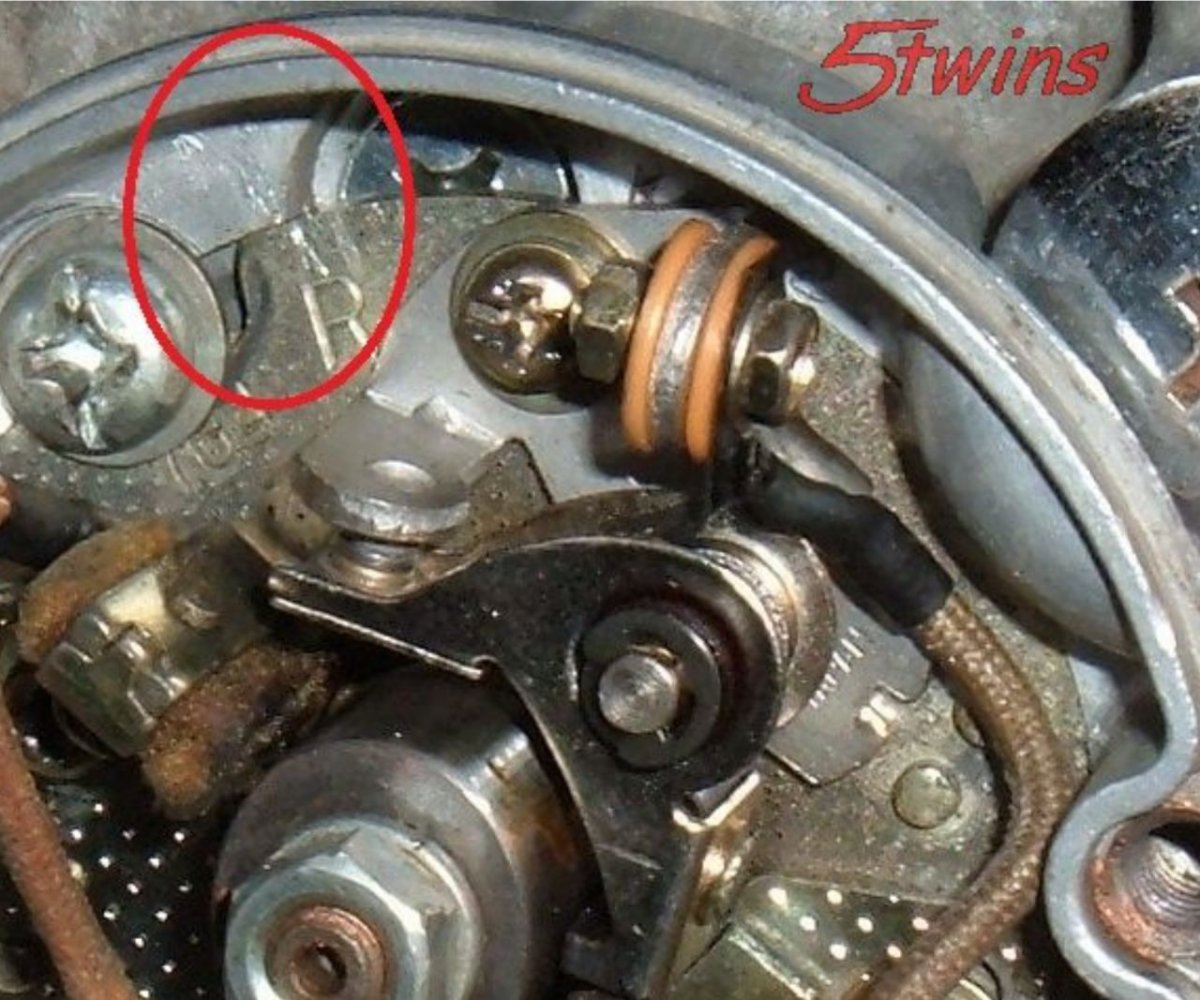

Wrong way, lugs opposite the springs.

Right way, lugs atop the springs.

- Remove the points plate, recheck advance rod motion.

- With the points plate removed, it's much easier to install the points wiring.

- Have the wiring lugs atop of the points springs.

Wrong way, lugs opposite the springs.

Right way, lugs atop the springs.

Bob, like gggGary alluded, the unlubed un-broken-in points followers have significant drag.

- Remove the points plate, recheck advance rod motion.

- With the points plate removed, it's much easier to install the points wiring.

- Have the wiring lugs atop of the points springs.

Wrong way, lugs opposite the springs.

View attachment 129835

Right way, lugs atop the springs.

View attachment 129834

View attachment 129837

Ok, thanks for that info Steve. I’ll give that a try!

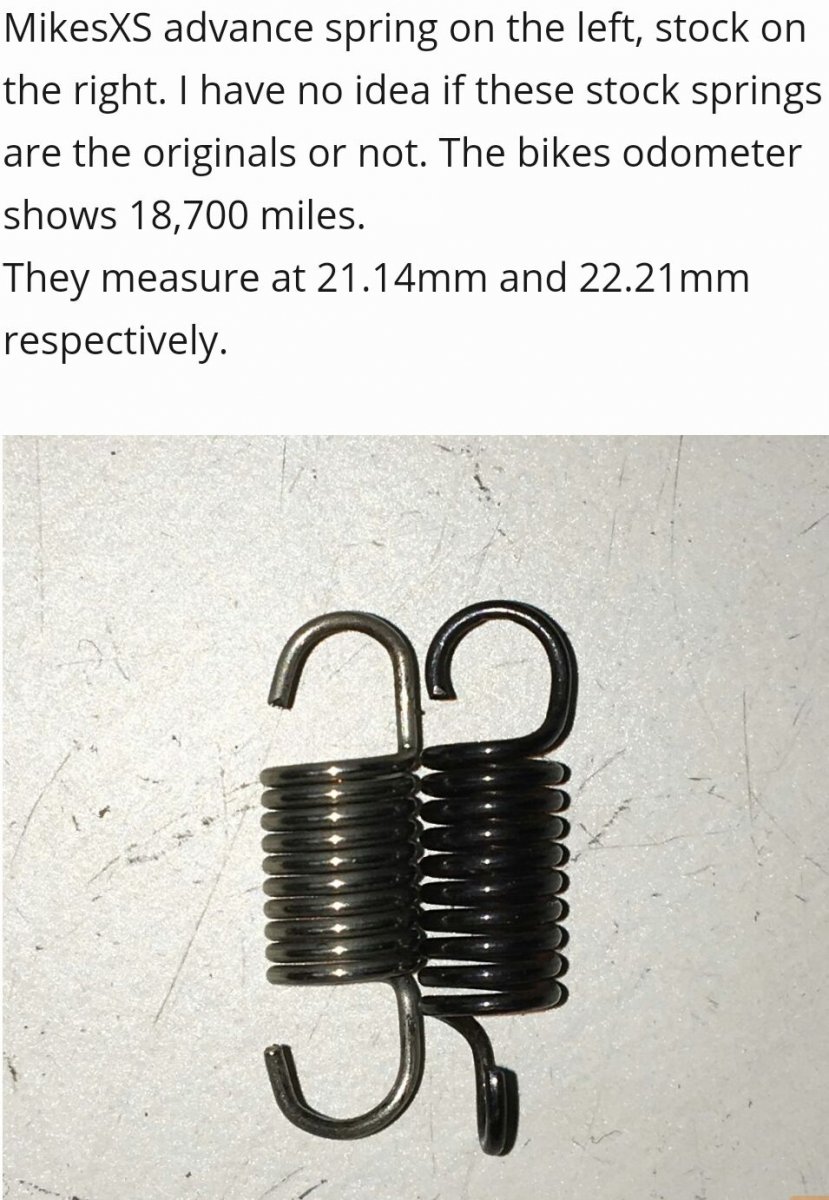

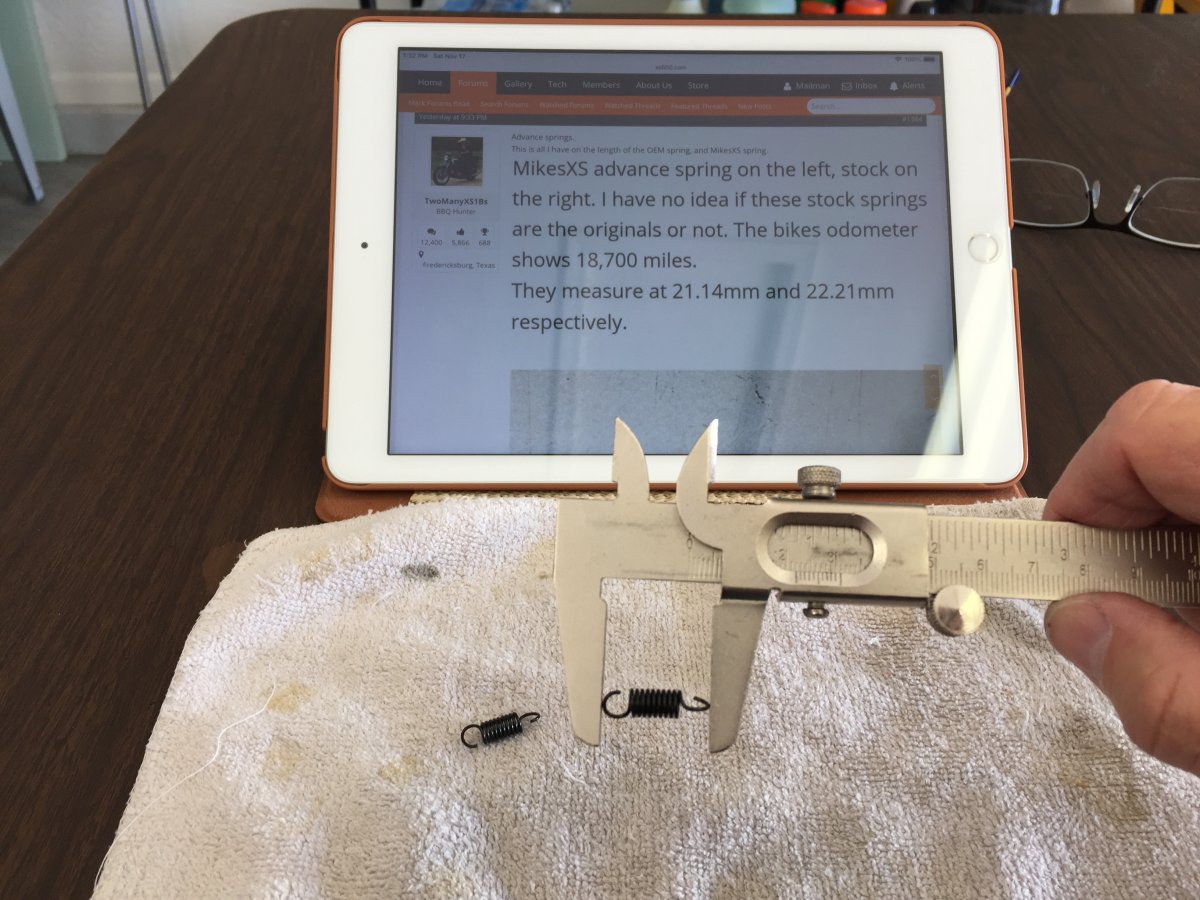

Advance springs.

This is all I have on the length of the OEM spring, and MikesXS spring.

This is a NOS advance unit, center slotted disc removed.

Note the spacing of the fully retracted weights.

Yours should be close to that.

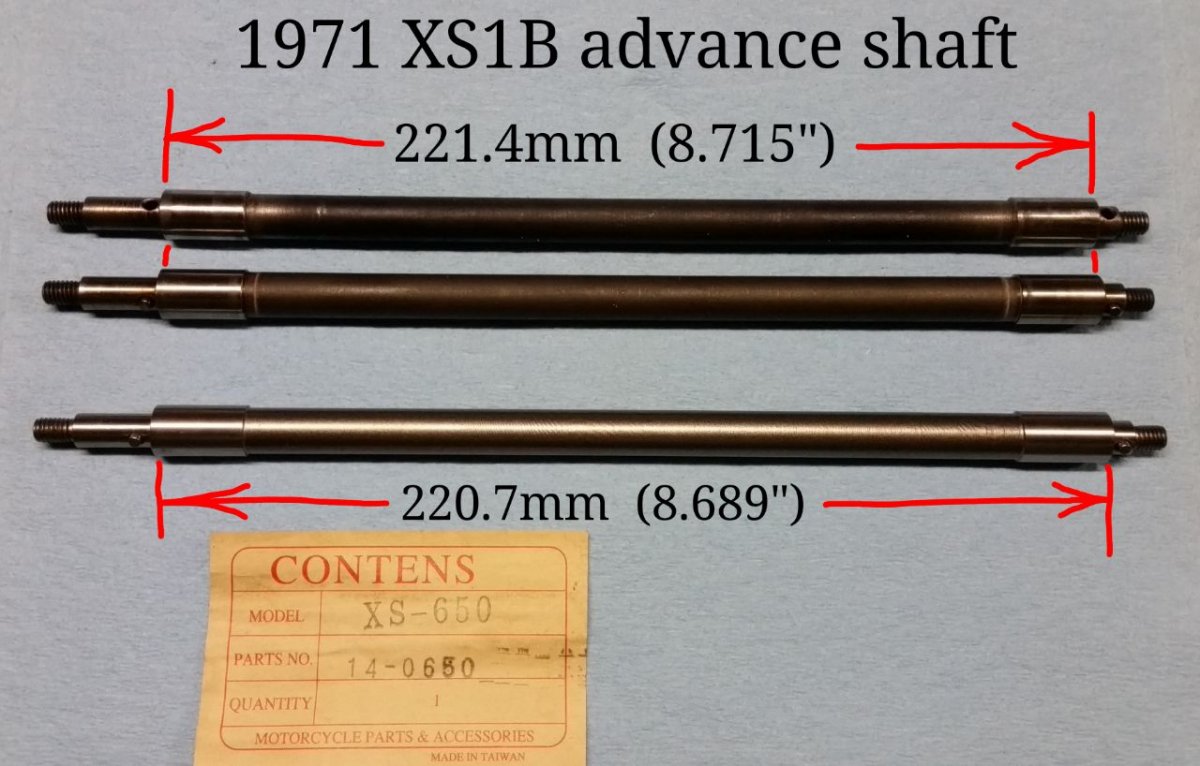

Check the endplay of your advance shaft. Normal is around 0.020", 1/2 mm. Less is better. If unsure, here's lengths of my Yamaha shafts and one of MikesXS too-short offering.

Lastly, my advance units used only 2 shims per flyweight pivot, one under, one atop. Check that yours aren't binding...

This is all I have on the length of the OEM spring, and MikesXS spring.

This is a NOS advance unit, center slotted disc removed.

Note the spacing of the fully retracted weights.

Yours should be close to that.

Check the endplay of your advance shaft. Normal is around 0.020", 1/2 mm. Less is better. If unsure, here's lengths of my Yamaha shafts and one of MikesXS too-short offering.

Lastly, my advance units used only 2 shims per flyweight pivot, one under, one atop. Check that yours aren't binding...

Last edited:

Terrific! Thanks again, all good reference material. I’ll give it a good look.

Yew betcha, Bob.

Your threads are so well depicted and detailed that they deserve this level of response...

Your threads are so well depicted and detailed that they deserve this level of response...

Yew betcha, Bob.

Your threads are so well depicted and detailed that they deserve this level of response...

Thank you. I really appreciate you saying that.

It has always been my hope that my meanderings might be useful to someone else.

Note 2M's N.O.S. advance unit pic - no shim washers under the e-clips. It's probably like all the ones I've encountered having just one shim per post, under the weight. But 2M says his XS1 has 2 per post, one under and one above the weight. Maybe eliminating all but one shim washer was a later model change.

As far as shimming the extra end play out of the advance rod goes, I think it helps. See here .....

http://xs650temp.proboards.com/thread/1372?page=2

As far as shimming the extra end play out of the advance rod goes, I think it helps. See here .....

http://xs650temp.proboards.com/thread/1372?page=2

5T's proboard post;

Apr 25, 2007 at 10:45am

Quote

Post by 5twins on Apr 25, 2007 at 10:45am

No problem. I feel this is one of the most overlooked and neglected maintenance items on the points equipped models, probably because folks just aren't aware that it needs to be done. It isn't mentioned in the maintenance sections of any of the manuals I've seen. I guess Yamaha didn't figure many of these bikes would still be runnin' around 25+ years later

. Service the rod and it will be good for many years to come. Just be aware that it's in there and needs checking and/or servicing occasionally. You can easily rotate the rod by hand to full advance and it should snap back smartly to retard if things are good.

. Service the rod and it will be good for many years to come. Just be aware that it's in there and needs checking and/or servicing occasionally. You can easily rotate the rod by hand to full advance and it should snap back smartly to retard if things are good.

A neat little low cost mod (less than $10) you can do while you're in there is shimming the end play out of the advance rod. I noticed mine had quite a bit. I could pull the rod out on the advance side and see it move. When I released it, it snapped back in with an audable "click".

I thought this might be happening while it was running and adding to the top end clatter.

It wasn't easy to measure, but near as I could tell, I had about .015" end play. I shimmed it down to about .005". You can't go too tight or the advance rod won't advance - it will bind up when you tighten the disc down. Check it by rotating it by hand.

Well, this didn't do anything for the top end noise but the bike seems to run

smoother. Now with a timing light, the marks don't seem to jump around as much.

I think this stabilized the timing and the advance curve a little bit.

A buddy of mine stamped me out a few shims at work in various thicknesses. I was

ready to buy some from McMaster-Carr and now that I know they do something, I

just might. A standard 1/2"I.D. size works. The rod is 12 or 13mm O.D. (I don't

recall exactly). They have metric ones in 12 and 14mm I.D.s but these only come

in 50 pks., way more than you need. The American sizes come in 10 pks. A pack

of .006"s and one of .002"s would allow you to shim from .002" up to way past

.020" in .002" increments. The 2 packs would cost you about $8, just like

buying a set of points. With the rod removed, place the shims on it behind the points cam. Re-assemble and check by hand for binding and end play."

ggg again- I've also observed the "jumpy" points advance with a timing light.

Apr 25, 2007 at 10:45am

Quote

Post by 5twins on Apr 25, 2007 at 10:45am

No problem. I feel this is one of the most overlooked and neglected maintenance items on the points equipped models, probably because folks just aren't aware that it needs to be done. It isn't mentioned in the maintenance sections of any of the manuals I've seen. I guess Yamaha didn't figure many of these bikes would still be runnin' around 25+ years later

A neat little low cost mod (less than $10) you can do while you're in there is shimming the end play out of the advance rod. I noticed mine had quite a bit. I could pull the rod out on the advance side and see it move. When I released it, it snapped back in with an audable "click".

I thought this might be happening while it was running and adding to the top end clatter.

It wasn't easy to measure, but near as I could tell, I had about .015" end play. I shimmed it down to about .005". You can't go too tight or the advance rod won't advance - it will bind up when you tighten the disc down. Check it by rotating it by hand.

Well, this didn't do anything for the top end noise but the bike seems to run

smoother. Now with a timing light, the marks don't seem to jump around as much.

I think this stabilized the timing and the advance curve a little bit.

A buddy of mine stamped me out a few shims at work in various thicknesses. I was

ready to buy some from McMaster-Carr and now that I know they do something, I

just might. A standard 1/2"I.D. size works. The rod is 12 or 13mm O.D. (I don't

recall exactly). They have metric ones in 12 and 14mm I.D.s but these only come

in 50 pks., way more than you need. The American sizes come in 10 pks. A pack

of .006"s and one of .002"s would allow you to shim from .002" up to way past

.020" in .002" increments. The 2 packs would cost you about $8, just like

buying a set of points. With the rod removed, place the shims on it behind the points cam. Re-assemble and check by hand for binding and end play."

ggg again- I've also observed the "jumpy" points advance with a timing light.

Last edited:

Thanks so much for all this material guys. I’ve got a lot to chew on!

Fun with points and advance unit Part 2.

Today I pulled the points plate back out and tried the action on the advance unit again. I also removed the E Clips and shims that were on top of the weights. I wanted to remove as much friction as possible.

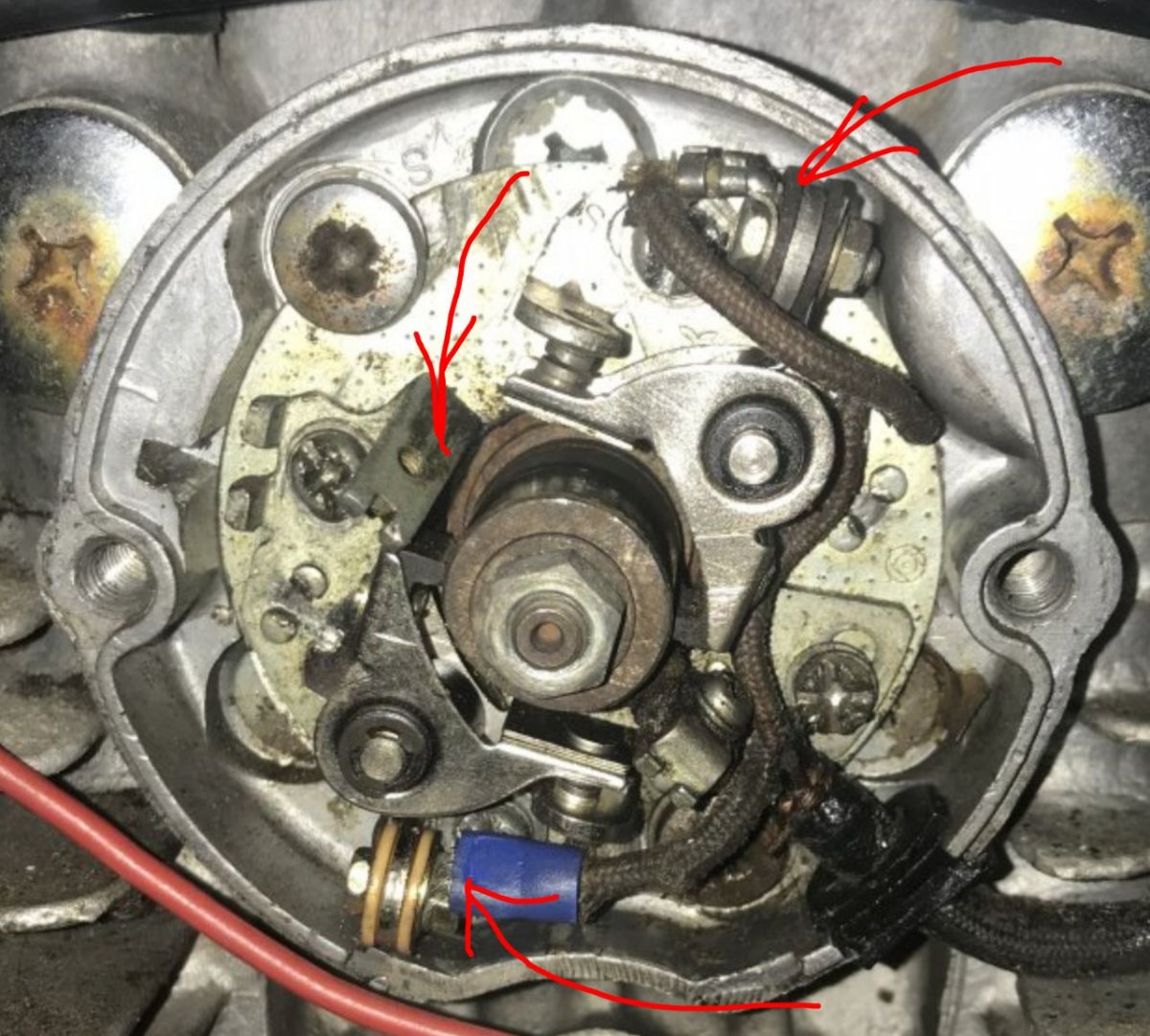

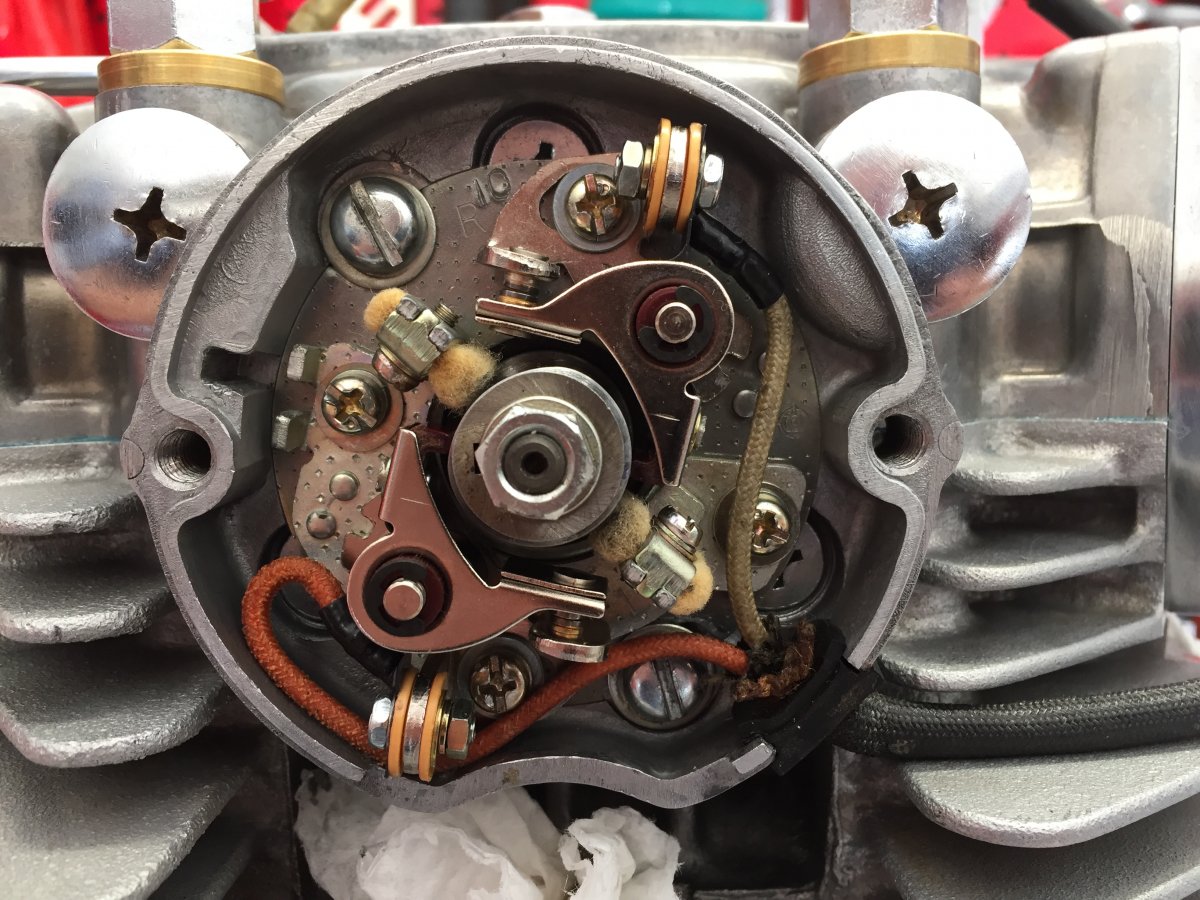

Here is how it looked.

Really pretty good. Still felt a little gummy but was closing up all the way, every time.

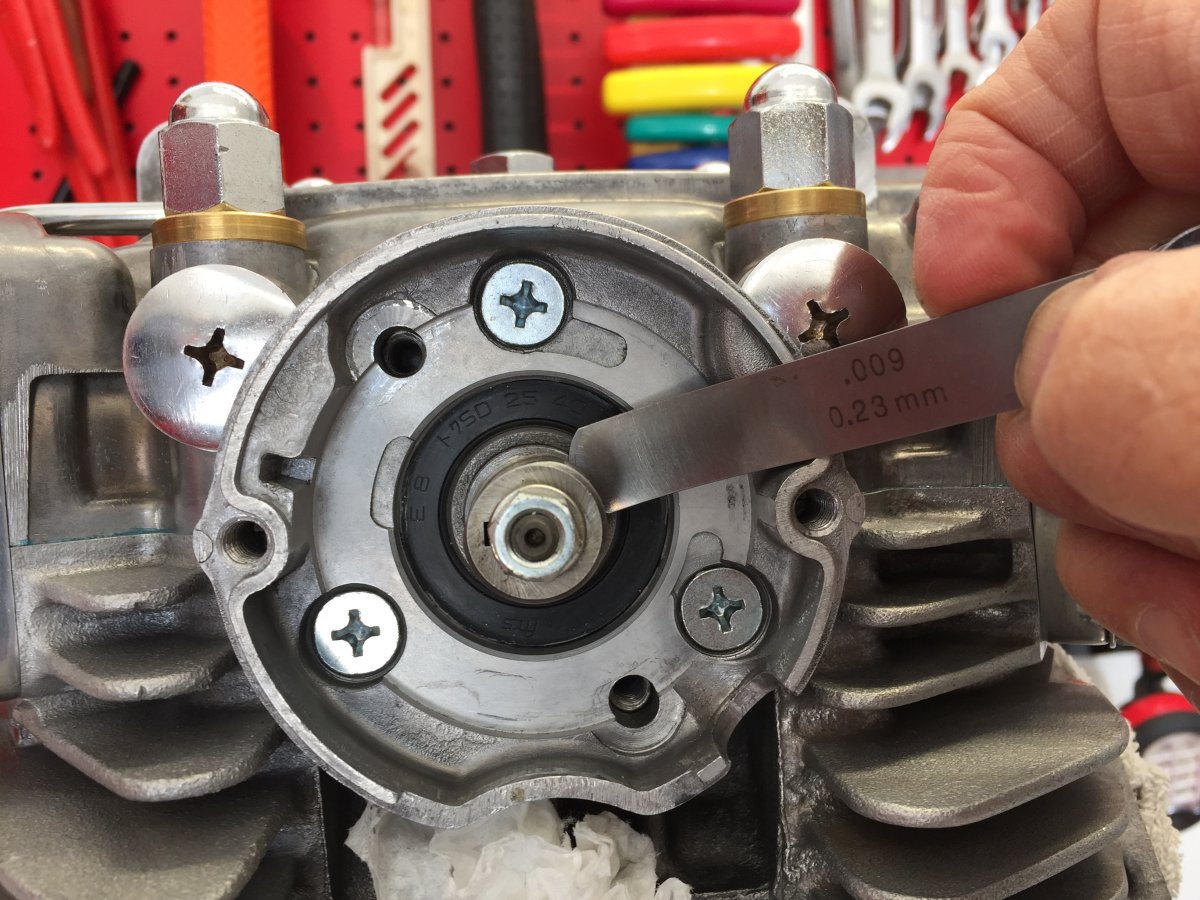

Next up, with the points plate out, I used feeler gauges to measure the amount of end play on my advance rod.

I came up with .009 inch clearance. Just the slightest end to end movement.

Then I measured my advance weight return springs against what 2M said he had with his original springs. Mine were nearly identical at 21.6mm for one and 21.8mm for the other. Also just like 2M’s my spring ends were 90 degrees offset from each other.

Then I cleaned all the grease that I had applied to the advance mechanism off, and instead used thinner 3 in 1 oil to lube all the moving parts.

I reassembled the advance mechanism, this time reducing the number of shims to one below and one on top, installed new E Clips and checked the action once again.

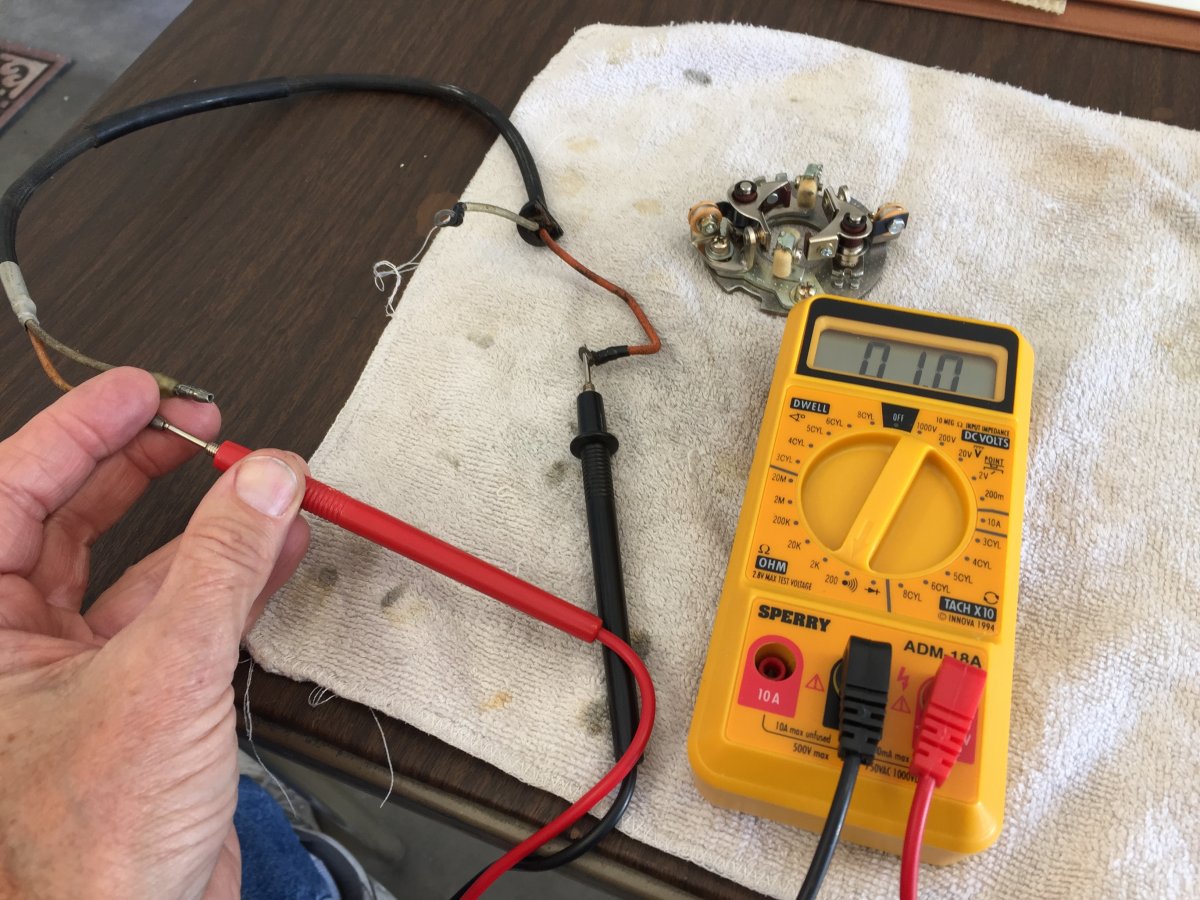

I then turned my attention to the points plate. Using the reference photos that Steve gave me last night ( which also matched my reference photos I took prior to disassembly) I wired up my points plate while it was out of the bike. Good tip! Much easier. Before wiring them up I shined up the connections with a dremel and wire wheel and checked the wires for continuity.

Points plate back in. By the way, I waffled on what to use to lubricate the felt pads and points cam. I could’ve used oil, but I used some silicone grease I have. We’ll see how that works.

And I checked the advance action yet again. It’s oddly sluggish, and the weights don’t retract all the way closed.

Even though in rotated the crank and tried it in different positions.

I really think it’s probably ok, I’ll just have to check it out after running it.

That’s all for today.

Time to hit the showers!

Bob

Today I pulled the points plate back out and tried the action on the advance unit again. I also removed the E Clips and shims that were on top of the weights. I wanted to remove as much friction as possible.

Here is how it looked.

Next up, with the points plate out, I used feeler gauges to measure the amount of end play on my advance rod.

I came up with .009 inch clearance. Just the slightest end to end movement.

Then I measured my advance weight return springs against what 2M said he had with his original springs. Mine were nearly identical at 21.6mm for one and 21.8mm for the other. Also just like 2M’s my spring ends were 90 degrees offset from each other.

Then I cleaned all the grease that I had applied to the advance mechanism off, and instead used thinner 3 in 1 oil to lube all the moving parts.

I reassembled the advance mechanism, this time reducing the number of shims to one below and one on top, installed new E Clips and checked the action once again.

I then turned my attention to the points plate. Using the reference photos that Steve gave me last night ( which also matched my reference photos I took prior to disassembly) I wired up my points plate while it was out of the bike. Good tip! Much easier. Before wiring them up I shined up the connections with a dremel and wire wheel and checked the wires for continuity.

Points plate back in. By the way, I waffled on what to use to lubricate the felt pads and points cam. I could’ve used oil, but I used some silicone grease I have. We’ll see how that works.

And I checked the advance action yet again. It’s oddly sluggish, and the weights don’t retract all the way closed.

Even though in rotated the crank and tried it in different positions.

I really think it’s probably ok, I’ll just have to check it out after running it.

That’s all for today.

Time to hit the showers!

Bob

I have an idea Bob, or anyone else for that matter.... We used this stuff on airplanes all the time.

When sprayed on, it looks like a grey primer.. and acts as one in that it'll seal against corrosion. It's a molybdenum base and it's super slick. I suspect that if you cleaned up all your advance parts with solvent and painted 'em with this stuff, you'd have an almost frictionless advance mechanism that was also rustproof and would last for years without any maintenance.

It ain't cheep. Found it on Ebay for 40 bucks a can.

When sprayed on, it looks like a grey primer.. and acts as one in that it'll seal against corrosion. It's a molybdenum base and it's super slick. I suspect that if you cleaned up all your advance parts with solvent and painted 'em with this stuff, you'd have an almost frictionless advance mechanism that was also rustproof and would last for years without any maintenance.

It ain't cheep. Found it on Ebay for 40 bucks a can.

I wonder if that's the drag of your points on the cam?And I checked the advance action yet again. It’s oddly sluggish, and the weights don’t retract all the way closed.

That spray lube looks like good stuff!

Yeah it could be the points dragging , it works freely with the points removed. I’ve checked nearly everything. I think it should work ok.

I hope....

Yeah it could be the points dragging , it works freely with the points removed. I’ve checked nearly everything. I think it should work ok.

I hope....

I've always used a moly type grease on the advance rod bushings. That's what the shop manual recommends. I also use it initially on the weight pivot posts when I take a unit all apart for a cleaning. Once assembled, to keep the posts lubed in the future, I hit them with a small shot of foaming chain lube. I do this after running while the unit is hot so the lube penetrates better. I also spread a drop or two on each spring so they're "wet" with lube.

Yeah... unless I'm smokin' something bad, the points dragging should help pull it into the retard position.Yeah it could be the points dragging , it works freely with the points removed. I’ve checked nearly everything. I think it should work ok.

I hope....

Well you KNOW what I'd be using to lube that advance..... LOL. For sure; solvent clean the rod to bare metal then chuck it up and work in the TDS. also on rubber seals, then light weight lube. I've done several OEM spring shortenings with success, Think there's one spring done like that in Resto for years now.

You wouldn't use 40 year old oil tech in your bike, why iggy? .

.

You wouldn't use 40 year old oil tech in your bike, why iggy?

.

.Forgot about your TDS stuff. Hows that work for corrosion protection?

dunnoForgot about your TDS stuff. Hows that work for corrosion protection?

Have a snap lock on outside dog run line grease oil etc. always disappears gets hard to slide. Last time I used plain TDS, about 2 months now, still moving very freely.

Yeah... unless I'm smokin' something bad, the points dragging should help pull it into the retard position.

So do you think I’m missing something here? Something I’m not seeing or thinking about? You saw the video of the advance action with the points removed, and it seemed to work ok. Yet when they were installed, the weights were back to being slow to return and wouldn’t completely close. Are you thinking this is a potential problem?

It’s this kind of stuff that usually makes me run and buy a Pamco! Ha!

Thanks Gary! Oh I’ve got the room, but it might take longer to get back than your painted tins!

Thanks Gary! Oh I’ve got the room, but it might take longer to get back than your painted tins!