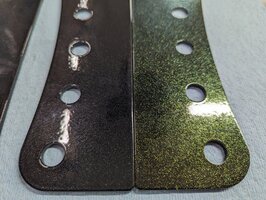

Playing around with different clears over a satin bronze today, in terms of the process, things are getting better! Starting to see better results. Getting close to choosing a color scheme for the bike so I can get on with the build!

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New here!

- Thread starter Peepz

- Start date

A few more powdercoat experiments this weekend. Tried the chrome version, came out great and I think this will be a viable option for some of the bike parts. Next I wanted to try a rim. It came out stunning but it has a few finish buggers where it sat on the oven racks. I won't be able to fit the 19" mags in the oven anyways. It really made me realize that I need to stick with smaller parts as my shop now looks like strip club with a layer of glitter on everything....

Attachments

Those look great!!

Wow. I'd love to see that on the back of an XS.A few more powdercoat experiments this weekend. Tried the chrome version, came out great and I think this will be a viable option for some of the bike parts. Next I wanted to try a rim. It came out stunning but it has a few finish buggers where it sat on the oven racks. I won't be able to fit the 19" mags in the oven anyways. It really made me realize that I need to stick with smaller parts as my shop now looks like strip club with a layer of glitter on everything....

Seems I need to visit a strip club...A few more powdercoat experiments this weekend. Tried the chrome version, came out great and I think this will be a viable option for some of the bike parts. Next I wanted to try a rim. It came out stunning but it has a few finish buggers where it sat on the oven racks. I won't be able to fit the 19" mags in the oven anyways. It really made me realize that I need to stick with smaller parts as my shop now looks like strip club with a layer of glitter on everything....

Guy I used to work with in the Air Force when I was stationed up in Alaska used to call me up and ask me if I wanted to go out "Christmas Shopping" with him.Seems I need to visit a strip club...

That was his code words to get past our wives for "Lets go visit the local strip clubs tonight!"...which Anchorage was pretty world renowned for at the time.

I was in one 14 years ago in Cocoa Beach. It just felt weird and uncomfortable...Guy I used to work with in the Air Force when I was stationed up in Alaska used to call me up and ask me if I wanted to go out "Christmas Shopping" with him.

That was his code words to get past our wives for "Lets go visit the local strip clubs tonight!"...which Anchorage was pretty world renowned for at the time.

Ok, had to get a better powder coat gun, the Eastwood wasn't cutting it. Anyways, decided on a couple pretty wild colors, Franken Sparkle for fenders, possibly tank,.etc. and a Heavy Black metallic for the frame components. I think it'll look pretty rad in the sunlight. here's a couple test panels with the green and the black metallic for the frame. I also got around to shooting the lower triple tree tonight, think it looks pretty cool! May be a little orange peel there, may have laid it on a tad thick, but nothing I can't live with. It's pretty hard to get the camera to pick up just how much metallic is in this black, it's a lot

Attachments

Nice! I like the green, unlucky color don'tch know (taboo). my sister has a jeep whatever,

looks black most of the time but in the right light the green metal color comes out.

planning to go that route with my tank and covers.

wish I had a v8, the vodkas a little dry!

looks black most of the time but in the right light the green metal color comes out.

planning to go that route with my tank and covers.

wish I had a v8, the vodkas a little dry!

That's the intent! Hopefully the entire bike will look black in low light, then really pop in the sun!Nice! I like the green, unlucky color don'tch know (taboo). my sister has a jeep whatever,

looks black most of the time but in the right light the green metal color comes out.

planning to go that route with my tank and covers.

wish I had a v8, the vodkas a little dry!

Hey guys, powder coated the lower legs. I'm rebuilding now with new seals and emulators. My question is the torque on the m10 lower bolt joining the upper and lower halves? Manual states 25 -29 ft lbs. For an M10 bolt, Seems a little strong in my opinion. What do you typically torque those to?

The manual has a miss print in the torque spec. You’re referring to the bolt on the bottom of the fork leg that goes into the damper rod. Torque is 14.5 ft lbs.Hey guys, powder coated the lower legs. I'm rebuilding now with new seals and emulators. My question is the torque on the m10 lower bolt joining the upper and lower halves? Manual states 25 -29 ft lbs. For an M10 bolt, Seems a little strong in my opinion. What do you typically torque those to?

View attachment 258543

View attachment 258542

This from the XS 650 SJ Service Manual. 19.6 Nm. 44.5 ft lbs is misprinted.

Oh wow, glad I asked. I ended up just going around 16ft lbs. Guess I'll just leave it there. Thanks!The manual has a miss print in the torque spec. You’re referring to the bolt on the bottom of the fork leg that goes into the damper rod. Torque is 14.5 ft lbs.

This from the XS 650 SJ Service Manual. 19.6 Nm. 44.5 ft lbs is misprinted.

Starting to come back together - you can see a motorbike taking shape . . .Not much. But a little progress!

Neat & tidy work shop BTW.

Do you guys think that fully welding these swingarms will invite stress cracks? I'm considering welding up these two small areas, mainly to keep corrosion out and to clean it up visually a bit. Or could it be that these areas were left unwelded to allow the swingarm a bit of flex when setting rear axle torque .

.

Attachments

Last edited:

I welded up all the open seams on my swingarm. Before you start, measure the distance between the axle plates. The heat will distort it. Then use a jack to open it back out to the correct distance.