Jeffy

XS650 New Member

Hey,

First Post!

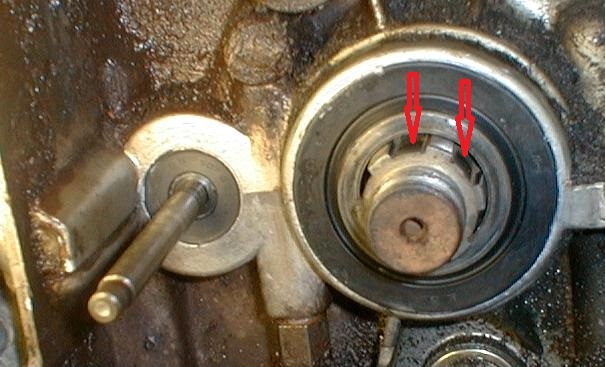

Recently swapped out the 530 chain and sprocket set for a 520 set. now when running i get a little bit of an oil leak. I tracked it down where the transmission output shaft meets the sprocket.

I *think* what's wrong can be attributed to me having about 1/16" wiggle in where the sprocket sits on the shaft. I went digging around thinking that maybe i forgot to purchase a spacer or bought a sprocket designed for a different set up, but after talking with MikesXS (and despite the indications on their website that the spacer is sold separately) there is actually no spacer needed for this setup.

Then I thought maybe I simply didn't tighten everything down correctly. So after another attempt at tightening it all down and still having this space, i took calipers to it. Measured the shaft, measured the recess in the nut, measured the thickness of the lock washer and the sprocket and right there in the numbers was the 1/16" of extra space that shouldn't be there.

Based on the amount of grime that was under the cover when i got this, I don't think this motor has ever been apart besides at the factory. My thought was that maybe the PO did some handy-man work in the transmission and left out some "unnecessary" parts during a rebuild. But, based on the quality of workmanship of the rest of the various hack-jobs on this bike, i suspect had the transmission been taken apart, it'd still be in pieces in his garage.

I've been digging around the forum looking for anyone that may a problem like mine. it appears from both here and my conversations with MikesXS that i truly am in a minority with this and i'm totally stumped. I've debated just buying a few of the lock-washers and stacking them up, but this is likely the wrong answer.

Anyway, if you've made it this far, thanks for reading and thanks for any and all advice you may be able to give.

Jeff

First Post!

Recently swapped out the 530 chain and sprocket set for a 520 set. now when running i get a little bit of an oil leak. I tracked it down where the transmission output shaft meets the sprocket.

I *think* what's wrong can be attributed to me having about 1/16" wiggle in where the sprocket sits on the shaft. I went digging around thinking that maybe i forgot to purchase a spacer or bought a sprocket designed for a different set up, but after talking with MikesXS (and despite the indications on their website that the spacer is sold separately) there is actually no spacer needed for this setup.

Then I thought maybe I simply didn't tighten everything down correctly. So after another attempt at tightening it all down and still having this space, i took calipers to it. Measured the shaft, measured the recess in the nut, measured the thickness of the lock washer and the sprocket and right there in the numbers was the 1/16" of extra space that shouldn't be there.

Based on the amount of grime that was under the cover when i got this, I don't think this motor has ever been apart besides at the factory. My thought was that maybe the PO did some handy-man work in the transmission and left out some "unnecessary" parts during a rebuild. But, based on the quality of workmanship of the rest of the various hack-jobs on this bike, i suspect had the transmission been taken apart, it'd still be in pieces in his garage.

I've been digging around the forum looking for anyone that may a problem like mine. it appears from both here and my conversations with MikesXS that i truly am in a minority with this and i'm totally stumped. I've debated just buying a few of the lock-washers and stacking them up, but this is likely the wrong answer.

Anyway, if you've made it this far, thanks for reading and thanks for any and all advice you may be able to give.

Jeff