Ok guys, an update. I have a letter done up with some corroborative editorial assistance from our MaximumPeter (oh, maybe that's that 2M guy with his crane in another thread) ready to send to Yamaha Corporate Parts Departments. Digging for contacts on that currently. My parts guru is checking with his contacts at Yamaha Canada to find the right person high enough up in the food chain to send it to. Will keep you posted on developments.

As well, I have decided to approach XS650 Direct here in Canada and Jim will deal with Mike's in the U.S.

Here is what I have forwarded to XS650Direct.

Dear Katie,

I am writing on behalf of the Yamaha XS650 enthusiast community which forms one of the core customer groups for XS650 Direct. As restorers, builders and riders of these bikes one of the biggest challenges we face is finding suitable replacement parts.

The efforts of your company to assist with these activities is truly appreciated. I know you work hard to provide authentic high quality parts and for the most part - you succeed admirably.

However sometimes factors that are out of your control go awry in the manufacturing process and the community has noted that when a problem is brought to your attention, you have taken prompt action and the issues were rectified.

Case in point the starter gear clip, your part #24-6522 (OEM Ref. #90468-29062 for starter gear #4):

While there have been reports in the past of cases of the rubber face delaminating, it would appear that specific issue has been resolved.

However, we have now discovered another serious problem with this part: the mounting hole boss castings are not properly cast and they are threaded at the incorrect angle. As a result, the part you are supplying cannot be used in the XS650 engine.

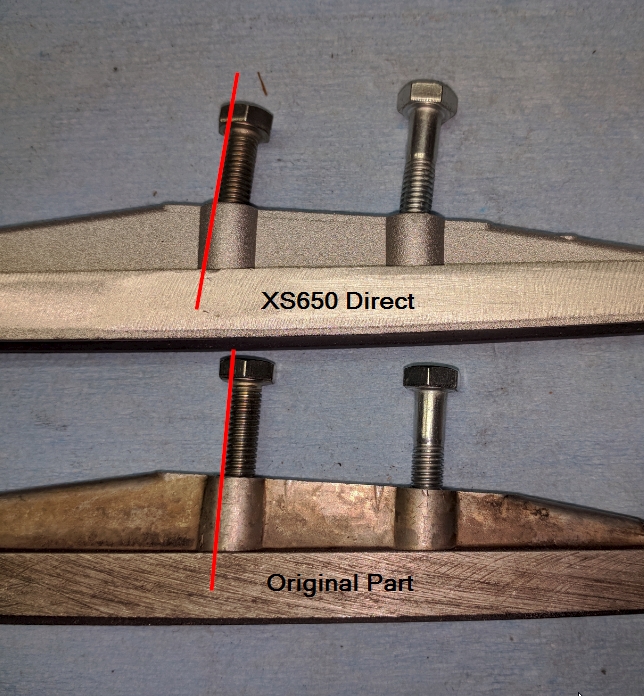

You can see in the attached pictures how the angle of these boss castings does not match that of the original Yamaha part. The top picture is a comparison of a part shipped from XS650Direct to the original Yamaha part. And the bottom comparison is a part shipped from MikesXS to a Yamaha original. You can see how the mounting bosses are cast perpendicular to the guide on your part whereas they are cast perpendicular to the mounting face on the original part.

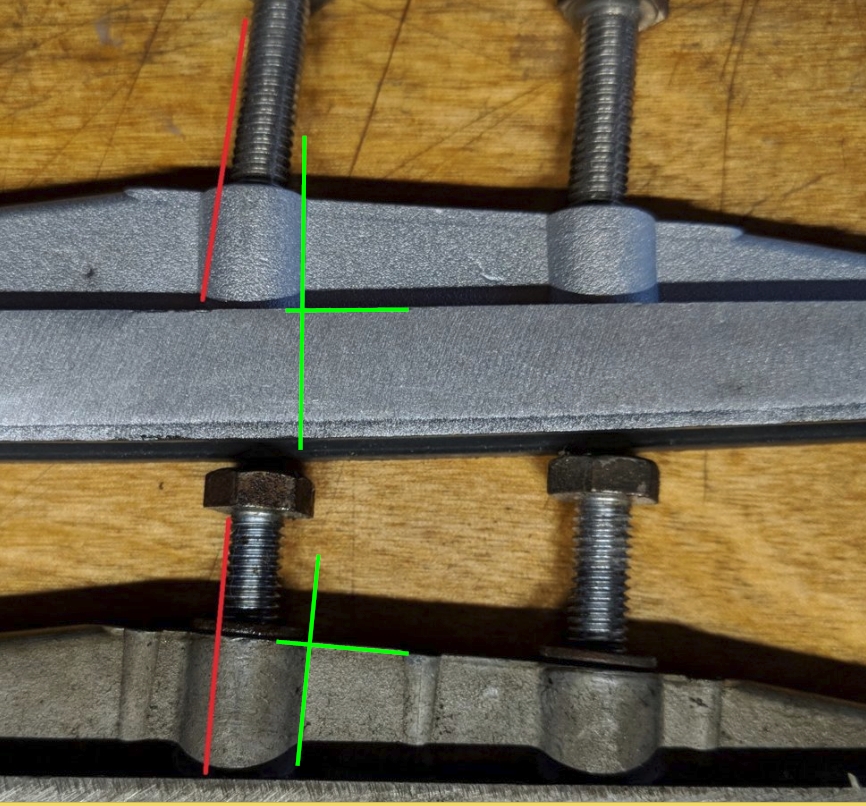

The differing angle can be seen in these comparisons as well.

Also of note the right side boss in the XS650Direct part in the rear of the above picture is not cleanly threaded deep above and thus would prevent a mounting bolt from fully seating.

In addition the angle of the mounting threads as shown in the pictures below is off a significant amount from those of the original. Once again, the top comparison is with a part shipped from XS650Direct and the bottom from MikesXS.

As you can appreciate this flaw affects the installation of this part and renders it unusable or at the very least extremely unsatisfactory.

The XS650.com community is keenly aware of this problem and there has been a considerable amount of discussion about this recently.

We realize that you need feedback from your customers about how the parts supplied by your companies are performing and so we hope that with this information, you can take the steps to correct this problem and reintroduce a quality part that is dimensionally correct and usable.

Thank you for your consideration and I look forward to hearing from you on this matter.

Sincerely,

Robin C

Well, let's see what happens guys.

As well, I have decided to approach XS650 Direct here in Canada and Jim will deal with Mike's in the U.S.

Here is what I have forwarded to XS650Direct.

Dear Katie,

I am writing on behalf of the Yamaha XS650 enthusiast community which forms one of the core customer groups for XS650 Direct. As restorers, builders and riders of these bikes one of the biggest challenges we face is finding suitable replacement parts.

The efforts of your company to assist with these activities is truly appreciated. I know you work hard to provide authentic high quality parts and for the most part - you succeed admirably.

However sometimes factors that are out of your control go awry in the manufacturing process and the community has noted that when a problem is brought to your attention, you have taken prompt action and the issues were rectified.

Case in point the starter gear clip, your part #24-6522 (OEM Ref. #90468-29062 for starter gear #4):

- Peter Frise from Windsor, ON raised the issue with this part, explained that the clip you were supplying was not formed to the correct dimensions and was made from wire that was too thin - and you folks had it corrected and a properly spec’d part is now being shipped.

- Thank you - VERY much - that type of responsiveness was noted and is very welcome indeed.

While there have been reports in the past of cases of the rubber face delaminating, it would appear that specific issue has been resolved.

However, we have now discovered another serious problem with this part: the mounting hole boss castings are not properly cast and they are threaded at the incorrect angle. As a result, the part you are supplying cannot be used in the XS650 engine.

You can see in the attached pictures how the angle of these boss castings does not match that of the original Yamaha part. The top picture is a comparison of a part shipped from XS650Direct to the original Yamaha part. And the bottom comparison is a part shipped from MikesXS to a Yamaha original. You can see how the mounting bosses are cast perpendicular to the guide on your part whereas they are cast perpendicular to the mounting face on the original part.

The differing angle can be seen in these comparisons as well.

Also of note the right side boss in the XS650Direct part in the rear of the above picture is not cleanly threaded deep above and thus would prevent a mounting bolt from fully seating.

In addition the angle of the mounting threads as shown in the pictures below is off a significant amount from those of the original. Once again, the top comparison is with a part shipped from XS650Direct and the bottom from MikesXS.

As you can appreciate this flaw affects the installation of this part and renders it unusable or at the very least extremely unsatisfactory.

The XS650.com community is keenly aware of this problem and there has been a considerable amount of discussion about this recently.

We realize that you need feedback from your customers about how the parts supplied by your companies are performing and so we hope that with this information, you can take the steps to correct this problem and reintroduce a quality part that is dimensionally correct and usable.

Thank you for your consideration and I look forward to hearing from you on this matter.

Sincerely,

Robin C

Well, let's see what happens guys.