Ristis

XS650 Member

Hello everybody!

I have been reading forum from some time, decided to start a new thread and this is my first post here. Let me introduce myself - my name is Hristo, 35, I am from Bulgaria - Eastern Europe. Don't have much experience with bikes - two years ago I restored an old Simson AWO Touren 250cc from 1956, which is pretty simple bike compared to XS.

Here in BG there is no XS650 bikes for sale, so I was forced to search it abroad and bought my XS650 SE '79 3L1 from Germany via e-bay. Previous owner was a german gay who used to travel around Europe and spent 66 000 km with it. Before 11 years he gave up with motorcycles and left the bike in his garage...

My goal is to make a street tracker looking bike, to remove unnecessary weight, and to assemble it as reliable as possible for short weekend ridings. "Paramun" is a name of a mountain.

Please excuse my English ...ask my teacher, I will try to post more pictures.

Any comments or questions would be highly appreciated!

What I had:

And some fragments of what I have done up to now:

- frame:

- Stainless engine mount:

- exhaust pipes modification:

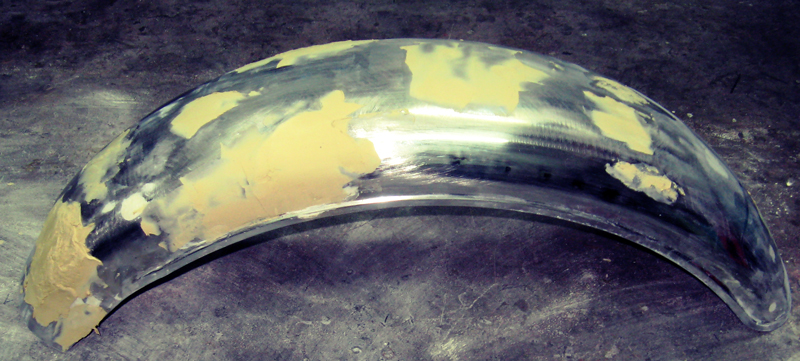

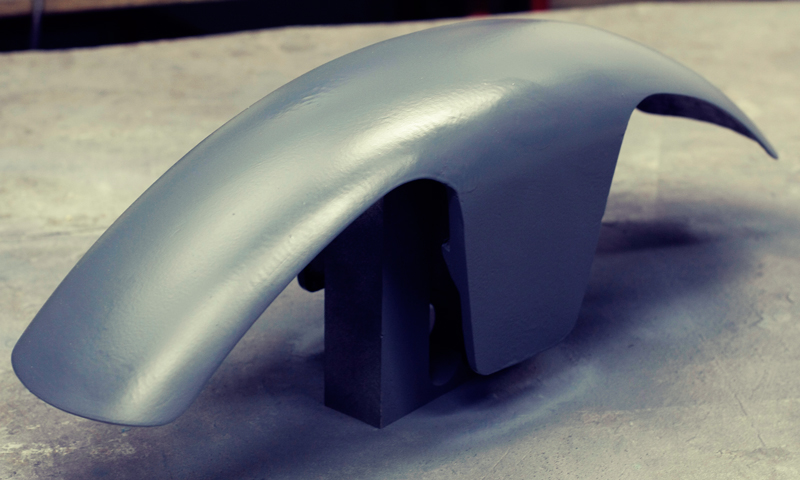

- carbon fenders:

- carbon seat pad:

- carbon electric box:

I have been reading forum from some time, decided to start a new thread and this is my first post here. Let me introduce myself - my name is Hristo, 35, I am from Bulgaria - Eastern Europe. Don't have much experience with bikes - two years ago I restored an old Simson AWO Touren 250cc from 1956, which is pretty simple bike compared to XS.

Here in BG there is no XS650 bikes for sale, so I was forced to search it abroad and bought my XS650 SE '79 3L1 from Germany via e-bay. Previous owner was a german gay who used to travel around Europe and spent 66 000 km with it. Before 11 years he gave up with motorcycles and left the bike in his garage...

My goal is to make a street tracker looking bike, to remove unnecessary weight, and to assemble it as reliable as possible for short weekend ridings. "Paramun" is a name of a mountain.

Please excuse my English ...ask my teacher, I will try to post more pictures.

Any comments or questions would be highly appreciated!

What I had:

And some fragments of what I have done up to now:

- frame:

- Stainless engine mount:

- exhaust pipes modification:

- carbon fenders:

- carbon seat pad:

- carbon electric box: