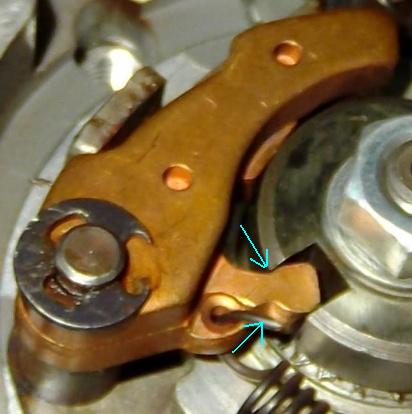

As far as I know, yes, they're all the same. In my mind, one of the issues with this set-up is the sharp corner on the slot that pushes the weight tab back to the retarded position. Over time this sharp corner starts cutting into the side of the tab .....

Although I haven't tried it, I've often thought maybe rounding that sharp corner off a little might reduce the wear on the tab, or at least slow it down. But it would probably increase the amount of advance too so you couldn't take much off, just "break" that sharp corner, round it off just a little bit.

Although I haven't tried it, I've often thought maybe rounding that sharp corner off a little might reduce the wear on the tab, or at least slow it down. But it would probably increase the amount of advance too so you couldn't take much off, just "break" that sharp corner, round it off just a little bit.