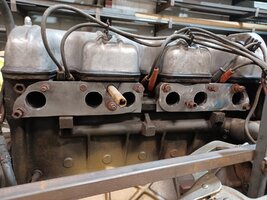

Engine mounts welded, plus got the transmission mount and cross member sleeved. Ended up I shoved a block at the rear and just let the front end droop and was able to roll the thing enough to get to the engine mounts without removing the power train completely. Plus the chassis got to roll which is awesome. I took a short video with it rolling but don't have the link handy to embed it right now.

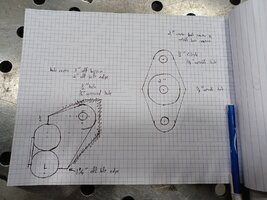

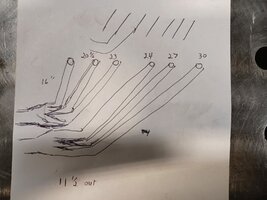

That was done early enough I started making lower coil over mounts for the front. Cut a little more material off them after the pictures and they're ready to weld to the control arms now and that's where I'll start tomorrow.