Gene

House of Detention

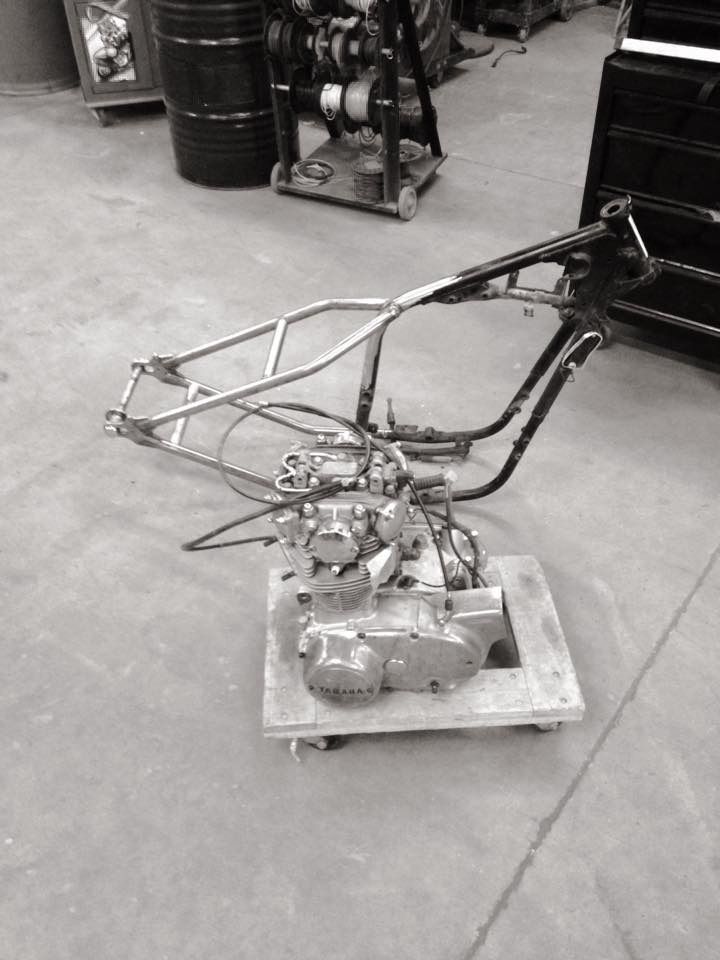

i ruined a XS...but should look cool when it's done. This is #2 of my XS650s (#1 still has suspension)

A. You lie.

B. looks like points opening on what kind? oscilloscope.

Sure feels like it. That's the 6th iteration of that circuit.

Good guess, kinda.

Keep your gloved fingers crossed that I can actually finish it...

Guess #2 the scope is reading the output of your DIY ignition circuit.

Gloves??? It's mitten weather here buddy.

Almost finished, I think...

Next guess; you are varying the condenser value so you can "even up" the cylinder timing without having to futz with L-R points relation. Or getting the optimum condenser value for non stock coils. or or feeding an electronic tach off the ignition circuit. OR a rev limiter for your hot cam, big carb motor.