There ya go.........Ride......

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What have you done to your XS today?

- Thread starter I am Carbon

- Start date

-

- Tags

- maintenance

Ok, I’ve had the bike running good and have ridden her around 50 miles since this afternoon. I have the original Green lit Tach, and the orange lit speedo I bought from Jim, and now I can’t decide which color I like better. I unplugged the turn signal canceler, and I have to insist that everyone should do the same. I have read so many posts about the “convenience”. Look, being on two wheels is not about convenience. Having your turn signals stop blinking while sitting at the light, or halfway through the turn, is not convenient either. God I wish I would have ripped that junk off months ago. So, what have I done to my XS today? including yesterday afternoon-

Retorqued head

Replace shit rubber washers with brass washers

Mount coil

Remove flasher canceling unit

Replace exhaust gaskets

Swap gauge cases from chrome back to black

Replace tachometer with original

Polish all chrome, wax all paint

Ride

You’re making good progress TZ, keep it up!

The setting sun has washed the burgundy out of the paint but here we are with the 76 on the lift preparing for a possible appearance at the fall 650 rally at Iron Horse.

Leaking petcock and float valve dumped gas into crank so I first drained that out then took off enough equipment from left side so that I could install a starter (that a PO had decided he did not need). Took the cleanest spare I had, tested it and went to install same.

First time doing this and what a chore. What with the exhaust crossover the centre stand and the exhaust pipes it was a real test of patience and (lack of) flexibility. Even on the lift. And yes, the PO painted the cases to match the tins.

The starter is on now and just have to get the gear cover on so I can jump the solenoid to see how bad or good the bendix spring is.

The starter plug I removed was a well crafted piece of kit.View attachment 122991 View attachment 122994 View attachment 122995

Great work Lakeview - you’re nearly there!

TZ - it sounds like you’ve got it on the run. Hang in there!

Pete

electra_boogaloo

XS650 Enthusiast

Installed some tc bros forward controls. Got some parts to make my own linkage to save a little$$$. Can anyone share pics or advice on how you modified your stock controls to the forwards?

WPGxs650_brat

XS650 Enthusiast

Not my thing, but that’s a nice clean build WPG!

Hey - how did you ground the bars for the horn switch? It looks like they’re powder coated right across the clamps....

Hey - how did you ground the bars for the horn switch? It looks like they’re powder coated right across the clamps....

WPGxs650_brat

XS650 Enthusiast

Not my thing, but that’s a nice clean build WPG!

Hey - how did you ground the bars for the horn switch? It looks like they’re powder coated right across the clamps....

Thank, clean is what I'm going for.

As far as I know that (your question) is a stock switch problem. For my 400 (TC bros bars, powercoat, stock switches), I used a word wheel on my grinder and took the powder coat off up to the switch. I have had no issues.

This new switch does not need to be grounded! Works like a gem. Only switch on my bars, the rest are hidden or relocated.

Attachments

Videos missing,,,,Here’s a video of my “new” clattering sound. Is this still acceptable or do I need to take another look at my valves?

Sorry about that- here we goVideos missing,,,,

Hey - that bike looks very nice indeed! As for the sound, it revs great - perhaps a bit ticky but not excessively so, in my view. Much bettter loose than tight valves for sure.

BTW - I think your petcocks are set on reserve - that’s a great way to run yourself out of gas....in the middle of,the night, on a dark lonely road, in the rain - far from a gas station.

DAMHIK....

BTW - I think your petcocks are set on reserve - that’s a great way to run yourself out of gas....in the middle of,the night, on a dark lonely road, in the rain - far from a gas station.

DAMHIK....

I rechecked the exhaust; they’re both still perfectly at .006”- its snug and .007” won’t fit. I set both intakes to where the .004” would be really tight, and then snugged it down to where I couldnt fit the .004” in at all. Sounds great now. No clatter at all.

I rechecked the exhaust; they’re both still perfectly at .006”- its snug and .007” won’t fit. I set both intakes to where the .004” would be really tight, and then snugged it down to where I couldnt fit the .004” in at all. Sounds great now. No clatter at all.

Last edited:

Yes, that sounds better, and good. These are old engines and an old design, so they do make some noise. You just want it to be a nice mechanical "tsk, tsk, tsk ....", not a pronounced "tick, tick, tick ....".

If you shop eBay at all, do a search occasionally for a Cal-Van #229 feeler gauge. They don't make them anymore and they only have 10 blades, but they are just the sizes needed for most bike work. This is my all time favorite feeler gauge .....

If you shop eBay at all, do a search occasionally for a Cal-Van #229 feeler gauge. They don't make them anymore and they only have 10 blades, but they are just the sizes needed for most bike work. This is my all time favorite feeler gauge .....

Indeed - a tsk tsk sound.

...like she’s scolding you for not going for a ride.

...like she’s scolding you for not going for a ride.

Ok, I just took her for about a 75 mile tound trip. Everything runs fine, but I noticed that when I go to accelerate now, there is just a split second of almost a stumble, and acceleration doesnt feel as strong as it was before the valve adjustment. Is that a result of the adjustment? Also, I noticed my base gasket is leaking. I torqued all 8 head bolts to 30 ft lbs and the two under the plugs to 16. I took each off, one at a time, and applied a little anti seize. Should I go any tighter to try to remedy the leak?

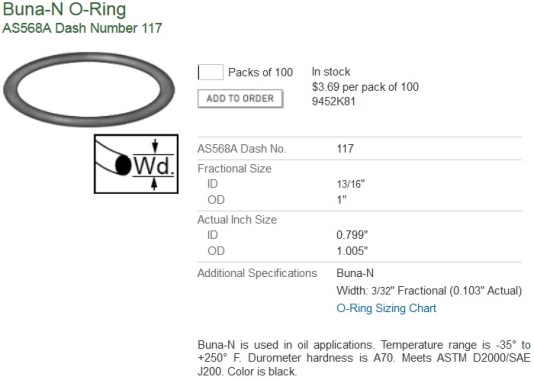

No, don't go any tighter. Sometimes a re-torque will fix leaking gaskets, sometimes not, luck of the draw I guess you could say. Clean the oil off then carefully watch and inspect the area around and below the cam chain adjuster. Many times a leak there can run down and appear to be a base gasket leak. There is an o-ring for sealing the large acorn cover nut on the cam chain adjuster on your model and it needs replacing quite a bit, like every couple of years. Luckily there's an American size that fits perfectly and is cheap .....

I know that what I’m about to say will turn a lot of the more fastidious people inside out, but I’ve always been a bit philosophical about a small oil leak.

I regard it as an indication that the engine has oil in it, and that the oil pump is working properly.

I’m not saying we shouldn’t strive for oil tightness and clean engines, but would I tear down an engine purely to cure a weeping head or base gasket.....not likely. It would just be added to the list of things I would be planning to fix once I did get into a full engine job.

....besides, you can buy a lotta oil for the price of an engine job.

I regard it as an indication that the engine has oil in it, and that the oil pump is working properly.

I’m not saying we shouldn’t strive for oil tightness and clean engines, but would I tear down an engine purely to cure a weeping head or base gasket.....not likely. It would just be added to the list of things I would be planning to fix once I did get into a full engine job.

....besides, you can buy a lotta oil for the price of an engine job.

This is my current philosphy.I know that what I’m about to say will turn a lot of the more fastidious people inside out, but I’ve always been a bit philosophical about a small oil leak.

I regard it as an indication that the engine has oil in it, and that the oil pump is working properly.

I’m not saying we shouldn’t strive for oil tightness and clean engines, but would I tear down an engine purely to cure a weeping head or base gasket.....not likely. It would just be added to the list of things I would be planning to fix once I did get into a full engine job.

....besides, you can buy a lotta oil for the price of an engine job.

Ride, enjoy, monitor and repair as necessary.

Similar threads

- Replies

- 32

- Views

- 2K