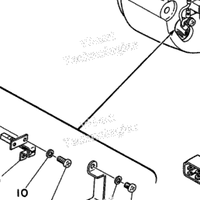

I just took the one brush out to determine if they needed to be replaced on my 73

When I went to put it back the spring and brush are on the wrong side of the bracket???

I know it's not magic and it's not happy hour yet WTF

When I went to put it back the spring and brush are on the wrong side of the bracket???

I know it's not magic and it's not happy hour yet WTF