And the build is waiting on my front end to get back from the machine shop. I couldn't cut it on my machine cause my 3 jaw chuck is wampus. You can make parts on it and cut them off but you can't put in existing stuff. I have like 4 chucks and 3 face plates but the spindles on them are too big. I did score a 4 jaw at the machine shop that has my front end but it doesn't go on all the way. Probably gonna have to clean up the treads.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's your thoughts in this lathe?

- Thread starter neanderthal

- Start date

-

- Tags

- fabricating tools

IMO the older craftsman lathes are not really that great but 100 times better than anything from HF. I did recently see a large Enco something lathe from Tawain that was really nice but it was also 13 thousand bucks.. I have a Southbend Heavy 10 built in 1969. It's old and crusty but amazing. Came with tons of tooling. My uncle owed me 300 bucks for working for him and gave it to me with a broken back gear which I found on ehay for 10 bucks. Then you join practicalmachinist.com and start the buying frenzy. A mill is soon after along with tons of tooling and measuring stuff. Say good bye to your money! haha. Love it.

Hi hotrod,

I may be blowing smoke but it's from an orifice that got it's machinist's papers at Rolls-Royce; don't sell those el cheapo machine tools short.

For serious steady work, yes, they are rubbish; but for Joe Amateur to make a small part on now and then, they'll do an OK job.

And the tool buying frenzy? Oh yes! Been there with air tools after I got my compressor. Got a closet full of them to prove it.

neanderthal

neanderthal

ok how about this one. its and older model, lady says its a 2006 and green as apposed to the red that they are putting out now...not sure if there was a quality difference in years with HF. 93799 is the model number and it comes with tools. She knows nothing about it, except that her neighbors came over to run it and said it works. Could probably get it for 250, shes looking for 300. But you can tell she wants it gone. Its a 7 x 12. So that means that i can do pieces up to 12 inches right? Will this also handle harder metals such as axles? I want being doing a lot of them, just want to have the option. This will be used for mostly smaller things such as bungs, spacers and such. I know nothing about lathes and have only used one that was cnc powered and had an expert behind me. thanks in advance.

ok how about this one. its and older model, lady says its a 2006 and green as apposed to the red that they are putting out now...not sure if there was a quality difference in years with HF. 93799 is the model number and it comes with tools. She knows nothing about it, except that her neighbors came over to run it and said it works. Could probably get it for 250, shes looking for 300. But you can tell she wants it gone. Its a 7 x 12. So that means that i can do pieces up to 12 inches right? Will this also handle harder metals such as axles? I want being doing a lot of them, just want to have the option. This will be used for mostly smaller things such as bungs, spacers and such. I know nothing about lathes and have only used one that was cnc powered and had an expert behind me. thanks in advance.

Hi jake,

like hotrod sez, it's Harbor Freight and you don't get what you don't pay for.

7 is 7" and that's the maximum diameter that won't hit the lathe bed.

What you can actually swing is somewhat less.

12 is the 12" bed length. Go measure the distance between the chuck and the tailpost.

'Nother thing to check is how big a bar will fit through the headstock.

You can work on longer stuff if it will fit through there.

Cutting steel on a bargain lathe is a matter of light cuts and tungsten carbide tooling.

Regard the purchase as a learning experience, you can always sell it off again.

neanderthal

neanderthal

yeah i figured as much, but some hf things are alright. all hf is crap, but not all is total crap. guess ill just save my funds up a bit and look in the 600 dollar range. thanks again

Problems with old lathes;

Worn ways. Probably the biggest "gotcha" issue on any used lathe is that the ways wear up near the head stock where 95% of the use is. The cure is going to cost 3 times what you paid for the lathe if you can find a shop to do it. I have an ancient 9" South bend I inherited from my dad and that's the big problem. There are some bandaids but it really limits accuracy.

Worn babbitt on the headstock bearings is probably the #2 problem although one cure for those (tapered rollers) isn't as expensive as having the ways planed.

But for what I do the old horse does the job.

Worn ways. Probably the biggest "gotcha" issue on any used lathe is that the ways wear up near the head stock where 95% of the use is. The cure is going to cost 3 times what you paid for the lathe if you can find a shop to do it. I have an ancient 9" South bend I inherited from my dad and that's the big problem. There are some bandaids but it really limits accuracy.

Worn babbitt on the headstock bearings is probably the #2 problem although one cure for those (tapered rollers) isn't as expensive as having the ways planed.

But for what I do the old horse does the job.

Those American Mini Lathes are cheap! Hell yeah. I'ma read up on that cool site.

http://www.taigtools.com/mlathe.html

Damn! Sweet! No threading though on any of these?

http://www.sherline.com/packages.htm

http://www.taigtools.com/mlathe.html

Damn! Sweet! No threading though on any of these?

http://www.sherline.com/packages.htm

neanderthal

neanderthal

oh man just the thought of sitting and enjoying coffee sounds good in it's self. ill have time sunday to do that a will read up on this. thanks.

ill read up on that first lathe link too hotrod, thanks for your input.

Last edited:

neanderthal

neanderthal

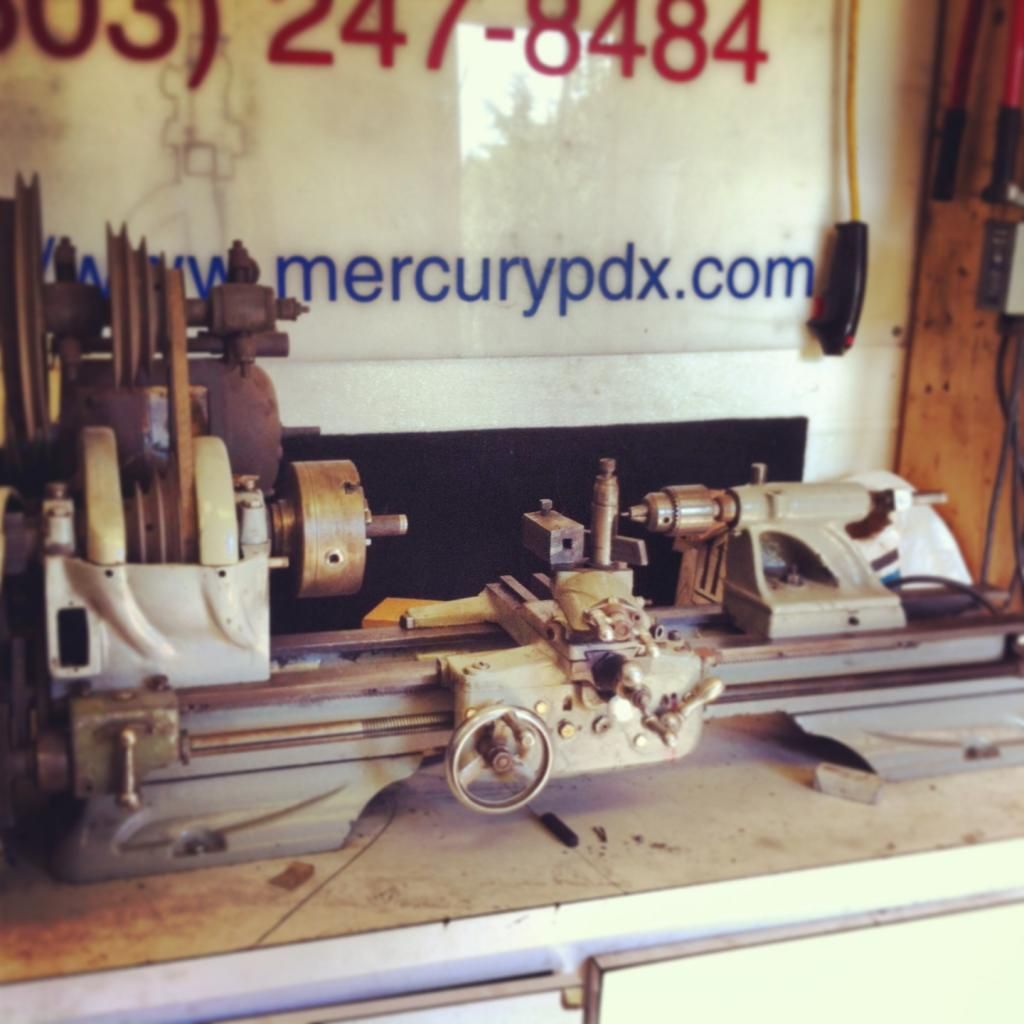

So i sold my 4runner today and first thing i did was hop on craigslist. I found a Lathe at a good price, and the guy put it in his truck drove it to my house and help carry it up a flight of stairs. As i no longer have a car as of now. I pulled the trigger on it as its a bigger lathe than ill every use and the cheapest i found yet. but im sure ill find a way too use its length. Seems everyone in the NW wants a lathe. Its a logan lathe and came with some gears and little tooling. Now its time to learn and also find some paper work for this guy.

RFLIVES

Resident Sidecar nut

you will use every bit of that bed length. Good score!

neanderthal

neanderthal

thanks, i think so too.

this probably is a long shot, but does anyone know the model # of this lathe? supposed to be on the way of the lathe. I think it got sanded down to where it has been removed.

this probably is a long shot, but does anyone know the model # of this lathe? supposed to be on the way of the lathe. I think it got sanded down to where it has been removed.

Oh, yeah, Logan, great lathe!

This site has a sub-forum that covers Logan lathes:

Http://www.hobby-machinist.com

This site has a sub-forum that covers Logan lathes:

Http://www.hobby-machinist.com

mrriggs

XS650 Junkie

Logans are great lathes.... but that's an Atlas.

Still a capable machine if you work within it's limits. New parts are still available from Clausing. Used parts are plentiful as well.

Still a capable machine if you work within it's limits. New parts are still available from Clausing. Used parts are plentiful as well.

neanderthal

neanderthal

Oh, yeah, Logan, great lathe!

This site has a sub-forum that covers Logan lathes:

Http://www.hobby-machinist.com

Hey thanks twomany! I joined the site, jumped some forum hoops for a few days and then was able to post a thread. within half a day i got my answer. its an Atlas / Craftsman 10 x 24, Model D/F series Sold in about 1950 or so. So i feel better about it being one of those two and now i can learn more about it. Thanks for the info on that forum, seems to be a friendly and very active.

neanderthal

neanderthal

mrriggs, looks like we tie for post timing haha. Thanks. Im still doing some research on it to see if its an atlas or craftsman. What do you think? also thanks for the info on Clausing i'll check them out.

mrriggs

XS650 Junkie

There should be a tag on the tail stock end of the bed. It doesn't matter much really. They were all basically the same. Only changes they made to the 10" Atlas/Craftsman was switching to roller spindle bearings from plain bearings (yours has plain bearings), and going to a "quick change" gear box (yours is "change gear"). The 12" model is also the same basic machine, just has taller castings for the head, tail stock, and compound slide. I think the carriage slide rails were a little thicker on some models but that is only an issue if you are changing the carriage.

neanderthal

neanderthal

yeah unfortunately there are no tags whatsoever, but id like to get them all back on there if that is possible. i noticed that the atlas seems dark grey and the craftsman a blueish grey. am i seeing this correctly or is it just coincidence? one other thing if you dont mind, i can put a quick gear change box on there correct?

I've seen some threads there on that conversion. Just gotta pile-drive thru all that info.

See you there...

See you there...

mrriggs

XS650 Junkie

For a commercial job shop, a quick change gear box makes sense. For a little hobby lathe it's not needed.

I cut, maybe, four different threads in a year with my change gear Atlas. It'll do pretty much anything (inch or metric) and it only takes a couple minutes to change the gears.

I cut, maybe, four different threads in a year with my change gear Atlas. It'll do pretty much anything (inch or metric) and it only takes a couple minutes to change the gears.