-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

XS1B cafe build

- Thread starter SurlyBoy

- Start date

Thanks Fred. I've run bikes with a race pattern shift before. My intruder chopper was that way and was my only bike for quite a while. I had trouble readjusting to a regular pattern after that.

I just flick the mounts to get an idea. They're a little too far up and back like this. I think I'll rework them for more of a mid-mount position.

I just flick the mounts to get an idea. They're a little too far up and back like this. I think I'll rework them for more of a mid-mount position.

Got a little done today. Ordered a set of those welded clipons from amazon. I have a lead on a 750 tank and want to pick up some extra peg mounts to try and fab up some homey made rear sets. That'll get the riding position dialed in so I can figure out the tail section

I started on that tonight. I'm borrowing Brassnecks idea and using the stock hinge mounts and latch so that I can lift the tail section open to one side and access the electrical stuff.

Making a plate first to mount the hinges and latch catch. The fiberglass will be molded onto that.

First thing was to remove the little mount for the seat hold. Purists avert your gaze

I'm going to set the base plate down almost flat on the frame rails and have it sit on the stock isolator mounts for the battery box

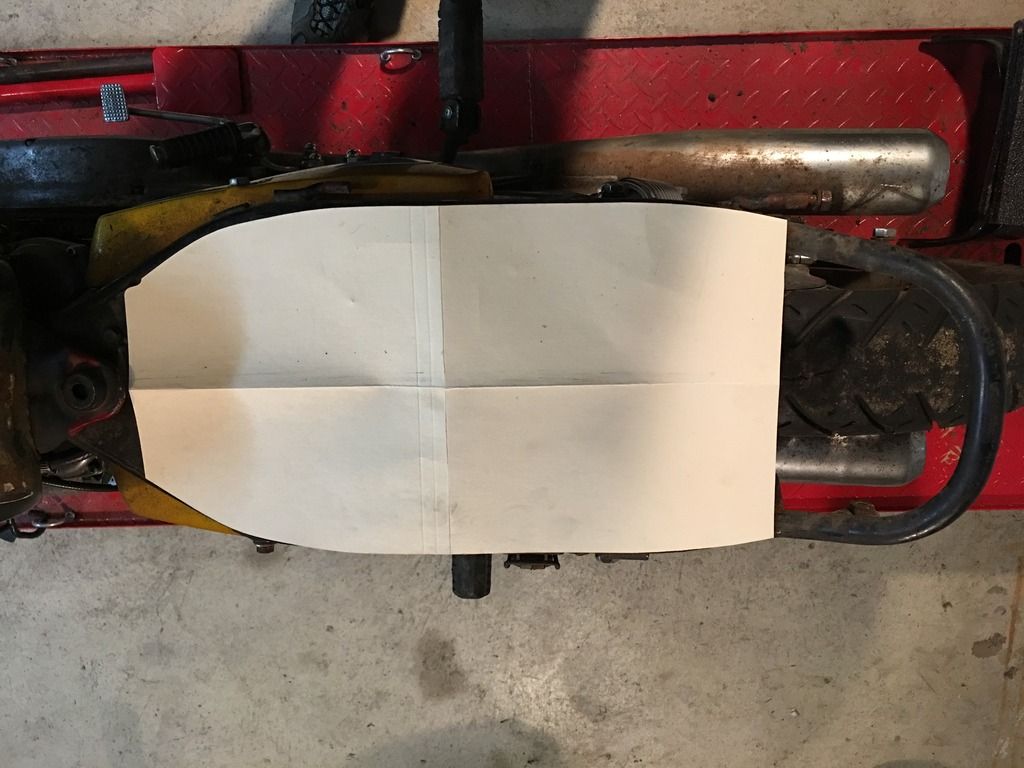

Made a paper template

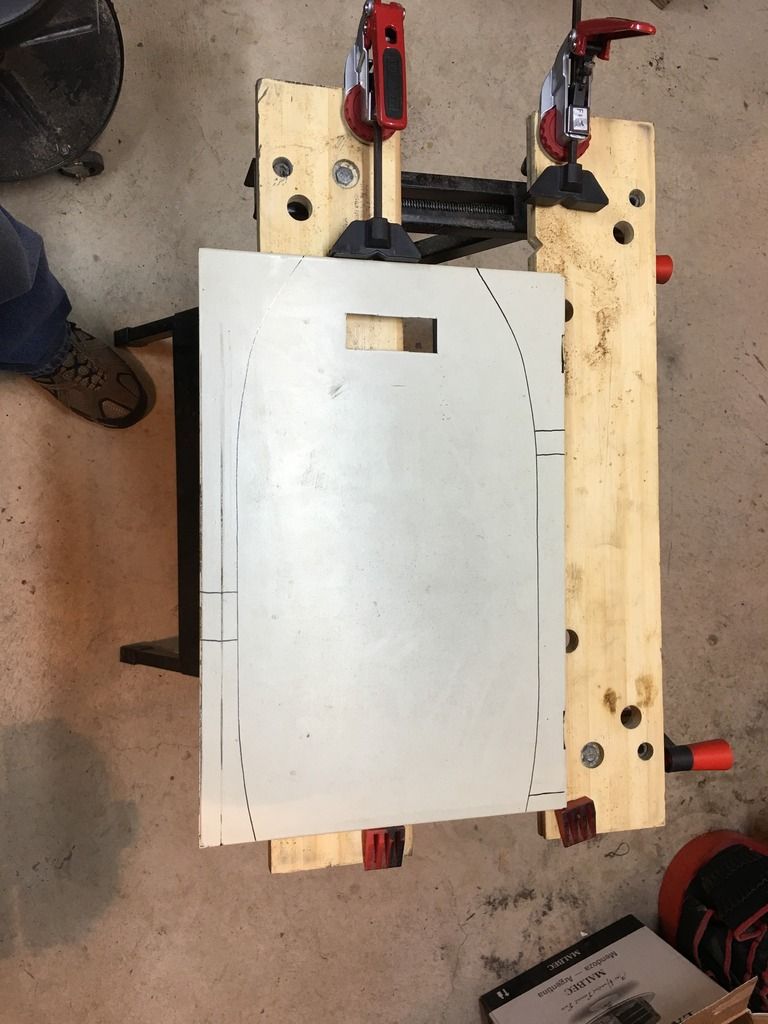

And transferred it to some 18 gauge steel from an old file cabinet

That's all I got done before I had to go back to work. I left the little tabs on the side where the latch and hinge line up to give me a little extra surface to weld on to

I started on that tonight. I'm borrowing Brassnecks idea and using the stock hinge mounts and latch so that I can lift the tail section open to one side and access the electrical stuff.

Making a plate first to mount the hinges and latch catch. The fiberglass will be molded onto that.

First thing was to remove the little mount for the seat hold. Purists avert your gaze

I'm going to set the base plate down almost flat on the frame rails and have it sit on the stock isolator mounts for the battery box

Made a paper template

And transferred it to some 18 gauge steel from an old file cabinet

That's all I got done before I had to go back to work. I left the little tabs on the side where the latch and hinge line up to give me a little extra surface to weld on to

While i was messing with the front end I started looking at how I might fit some sort of fork brace. There are two bungs (heh heh, buuuunngggg) lower down on the fork legs. I'm thinking I can use them to mount a horseshoe type brace under the fender. Won't be the best but will help firm it up a little

Finished the the hinges and latch for the seat pan. I'm using the original mounts and the whole tail section will swing up like the stock seat, instead of bolting on like most people do it. The sheet metal is thin but will be epoxied into the base of the fiberglass. It's just easier to locate the hardware on the sheet metal than try and build them into fiberglass.

Glued up some foam to start laying out the form for the fiberglass. Not sure if this polystyrene will work. It's hard to cut and breaks off in bubbles. It's what I had handy so I'll give it a shot. Might have to go and get some pink panther insulation board. That seems to work better

Glued up some foam to start laying out the form for the fiberglass. Not sure if this polystyrene will work. It's hard to cut and breaks off in bubbles. It's what I had handy so I'll give it a shot. Might have to go and get some pink panther insulation board. That seems to work better

Dug up a headlight bucket from the parts stash. It has the same style ears and fork tube covers as the stocker but is shallower, which is fine because I won't need to stuff all the electrical connectors inside. Running a simple headlight/tail light setup. It will hopefully fit tighter to the steering stem and make the front end loom shorter and neater. Just need to flip the bucket and shorten the tubes

Experiencing some serious deja-'vu here.

1974, cafe'ing my XS1B, Atlas lathe a'waiting in the backround.

Real interested in your fork brace solution...

1974, cafe'ing my XS1B, Atlas lathe a'waiting in the backround.

Real interested in your fork brace solution...

Template for the tail section. It looks a little long in the front but there'll be an inch or so of seat padding that'll fill in the shape

I'm wondering if the top of the tank should be in line with the top of the rear hump. I might put longer shocks on so I don't want it to look too ass high

I'm wondering if the top of the tank should be in line with the top of the rear hump. I might put longer shocks on so I don't want it to look too ass high

Starting on the form for the tail section. Made a template of the top of the frame

And transferred it to the bottom of my foam core. Using the tank mounting pin as a reference point.

Then carried the profile out about an inch to give me some wiggle room for shaping the sides around the frame rails

Outlined the side view template on each side of the core

And transferred it to the bottom of my foam core. Using the tank mounting pin as a reference point.

Then carried the profile out about an inch to give me some wiggle room for shaping the sides around the frame rails

Outlined the side view template on each side of the core

Last edited:

I thought about making a hot wire cutter but decided since this is just a trial run (I've never done fiberglass before) to just heat up an old fillet knife

It cuts through the foam nicely but cools quickly so I had to keep reheating the knife

Got a rough shape going. It needs to get trimmed down and smoothed out. The styrofoam isn't easy to shape. I picked up some pink panther insulation that is supposed to be better for working with. As it is I spent about $25 on foam, and I'll probably have to spend another 30 on fiberglass and resin. So I could spend half the price of a premade universal tail section, and end up with something that looks like crap. I work at it for a little bit but it might end up being easier to modify a generic tail section than start from scratch

It cuts through the foam nicely but cools quickly so I had to keep reheating the knife

Got a rough shape going. It needs to get trimmed down and smoothed out. The styrofoam isn't easy to shape. I picked up some pink panther insulation that is supposed to be better for working with. As it is I spent about $25 on foam, and I'll probably have to spend another 30 on fiberglass and resin. So I could spend half the price of a premade universal tail section, and end up with something that looks like crap. I work at it for a little bit but it might end up being easier to modify a generic tail section than start from scratch

It transforms the look of the bike

Working on getting it mounted. One set of cups has to go.

Since I'm more comfortable welding on the frame than the thinner sheet metal of the tank I'm going to modify the frame side of the equation. Drilled out the spot welds and knocked off the cups with a chisel

They're still intact and can be welded back on the frame easily. I'm going to leave the punch marks visible so that everything will line up if I need to return it to stock

Working on getting it mounted. One set of cups has to go.

Since I'm more comfortable welding on the frame than the thinner sheet metal of the tank I'm going to modify the frame side of the equation. Drilled out the spot welds and knocked off the cups with a chisel

They're still intact and can be welded back on the frame easily. I'm going to leave the punch marks visible so that everything will line up if I need to return it to stock

I cut down the stock XS650 rear bumper on the bandsaw. It's fairly petrified but will work for mockup

As it sits right now the cups are 1/4" narrower than the frame. It looks like if I put the pucks on the tank and the cups back on the frame I'm going to run into the same clearance issue. I'm going to have a think on it for a little bit

As it sits right now the cups are 1/4" narrower than the frame. It looks like if I put the pucks on the tank and the cups back on the frame I'm going to run into the same clearance issue. I'm going to have a think on it for a little bit

Looking good Surley Boy - I like your seat and the 750 tank look, and I do like your efforts to preserve that valuable old bike.

For help on the seat, you might want to check out a UTube channel called Hack a Week. The guy's name is Dino Segovis and he did a excellent transformation of an old Honda VF750 Sabre into a cafe bike - including making his own foam cutter (quite simple really) his own cafe seat and a even a fuel tank all using the lost foam process.

He shows step-by-step, very clearly how to do it - and it's quite inspiring. Note: there are around 40 episodes of about 30-40 minutes each, but it is worth it. Segovis is a very good mechanic and a truly creative guy - and it's easy to get totally hooked watching him work. He does a fine job on the videos - and he avoids usual swearing and filming with some stupid music playing in the background.

Anyhow, well worth a look.

Pete

For help on the seat, you might want to check out a UTube channel called Hack a Week. The guy's name is Dino Segovis and he did a excellent transformation of an old Honda VF750 Sabre into a cafe bike - including making his own foam cutter (quite simple really) his own cafe seat and a even a fuel tank all using the lost foam process.

He shows step-by-step, very clearly how to do it - and it's quite inspiring. Note: there are around 40 episodes of about 30-40 minutes each, but it is worth it. Segovis is a very good mechanic and a truly creative guy - and it's easy to get totally hooked watching him work. He does a fine job on the videos - and he avoids usual swearing and filming with some stupid music playing in the background.

Anyhow, well worth a look.

Pete

Hi SurlyBoy,

couple of things:-

MikesXS catalog has fork tubes in it.

Styrofoam dissolves in fiberglass resin. Urethane foam don't.

couple of things:-

MikesXS catalog has fork tubes in it.

Styrofoam dissolves in fiberglass resin. Urethane foam don't.

Yup, I was going to say (and I realise it's a bit late for this....) the white styrofoam is pretty horrible stuff to carve and it may die in the fibreglassing process. The pink or blue stuff is much better for this task I think.