Yamaha_chop

Fabricator Extraordinare

I thought about it, but my megasquirt isn't set up for sequential injection, it's batch fire only.

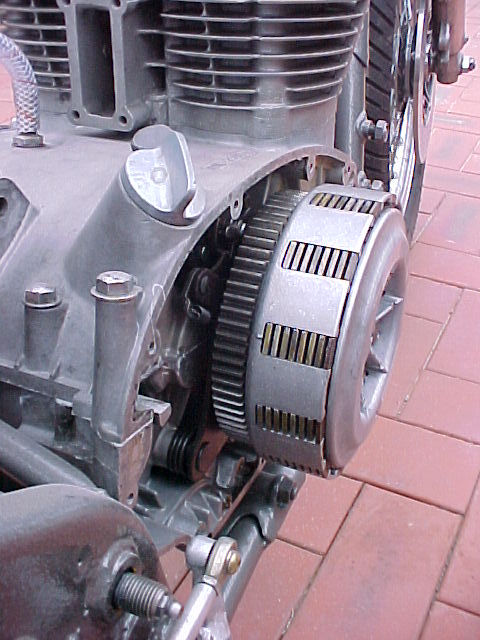

How about a clutch mod that would help these bikes shift bette?

hey hugh, how did you hold onto the pressure plate when you machined it? i cant seem to think of a way to hold it in the 4 jaw lathe i have here at work. thoughts?

I've got some updates - but I'm in the middle of moving shops, trying to buy a house, and offering new services... I'll do some more testing and get back to ya