truenorthmetal

XS650 Addict

I just installed the Complete Pamco Electronic Ignition Kit, #14-0902...and I have a few questions if any one could help that would be great.

1 - I received 3 pins - one went in the cam on the right side to locate the advance unit. The other 2 sounded like they were destined for each end of the advance rod....but there were pins already in the advance rod.....so out of the 3 pins I received....I only used 1.

Does that sound right or did I miss a secret pin install...?

2 - I was reading Hughs install guide as well as Pete's.....Hugh's showed a rotor with 2 magnets, and he said with left cylinder at TDC....magnets would align horizontally.

My rotor has 4 magnets....and they did not align horizontally....? Looking further, I now know there are 90 deg rotors and 60 degree rotors....mine appears to be a 60.

Do I need a 60 or a 90, and do my magnets need to align horizontally while I am at TCD...?

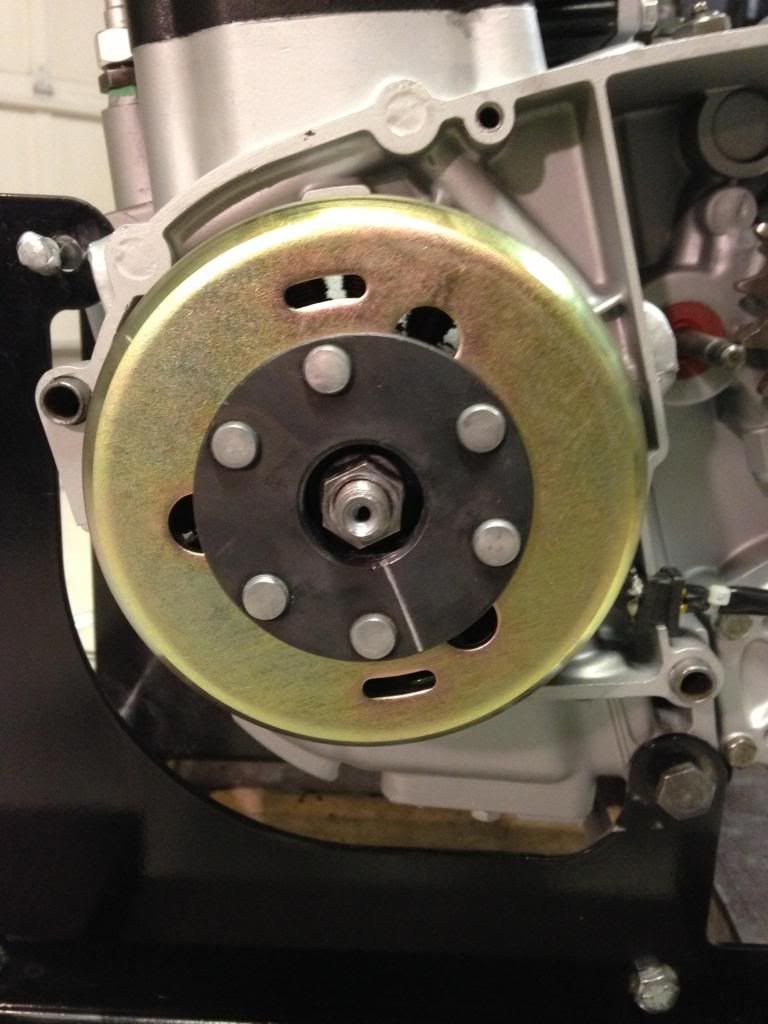

Below is the PMA while left cyl is at TDC - yes I am positive !

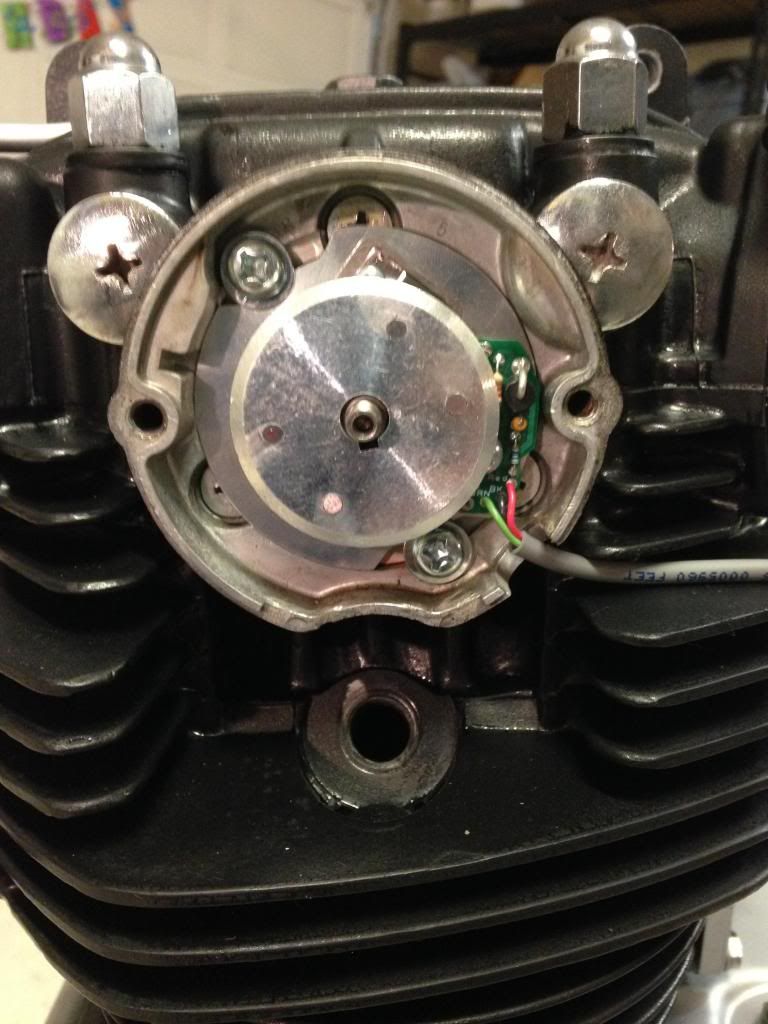

Next pic is advance unit while at TDC

and rotor assembly while at TDC

1 - I received 3 pins - one went in the cam on the right side to locate the advance unit. The other 2 sounded like they were destined for each end of the advance rod....but there were pins already in the advance rod.....so out of the 3 pins I received....I only used 1.

Does that sound right or did I miss a secret pin install...?

2 - I was reading Hughs install guide as well as Pete's.....Hugh's showed a rotor with 2 magnets, and he said with left cylinder at TDC....magnets would align horizontally.

My rotor has 4 magnets....and they did not align horizontally....? Looking further, I now know there are 90 deg rotors and 60 degree rotors....mine appears to be a 60.

Do I need a 60 or a 90, and do my magnets need to align horizontally while I am at TCD...?

Below is the PMA while left cyl is at TDC - yes I am positive !

Next pic is advance unit while at TDC

and rotor assembly while at TDC

and I have been known to be wrong on many occasions.

and I have been known to be wrong on many occasions.