What is off topic p nut? I'm still talking about slide action. My question to you has to do with your statement that the slide couldn't be lifted all the way with the hole covered.don't take this thread off topic WER

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Almost got her tuned juuuuust right

- Thread starter vincejames

- Start date

vincejames

XS650 Addict

Use finger nail polish/super glue at the slide and diaphragms junction. Make sure you have the slide oriented before applying.

Use grease/vaseline at the where the diaphragm seals to the body.

Okey dokey! I'll give it a try

Thank you for the edit. Makes a lot more sense now. Well, can't take a picture as I am currently at work. So let me just make sure I understand this correctly.

The proper way to test my brand new diaphrams that I installed from JDM is to lift the slide with my finger, while it is lifted up, block the vent hole. If it drops, then there is a leak or the seal is not perfect. If it stays elevated in the air and does not drop then there is nothing wrong with the seal and it is working perfectly. This would make sense.

I read some older posts about the JBM diaphragms and there being issues with them not sealing correctly and in some cases the slides would twist out of place. It's hard for me to understand HOW I'm going to get the diaphragms to stay put. When the diaphragms caps are off you can easily pull the diaphragms off of the seal as you go in a circle around the diaphragm body. Should I be super gluing them or something? I don't see Vaseline working that well....

No do not glue round the edges of the diaphragms

(edited for clarity )

(edited for clarity )Look ... place a drinking a straw in a glass of milk and suck the milk up to the top of the straw. If you place your finger on the top of the straw the milk stays where it is ....why is that? It is because in order for the milk to drop something (air) must take the place of the milk. But nothing can get into the straw because you've blocked the top off with your finger.

However if you lift your finger off the top of the straw slightly the air rushes in allowing the milk to drop. That is the principle.

Your air leak is probably absolutely miniscule ...much less than the size of the hole in a drinking straw . By smearing vasoline around the edge of the diaphram it can prevent tiny air leaks from slight imperfections on the carb body or cap. You shouldn't need to put anything on your new diaphrams if they have been fitted properly.

Last edited:

I think some put a dab of Super Glue between the slide and diaphragm so they don't twist in one another. I don't think the JBMs have a locating tab on their outer edge like the originals did. You just have to get the slide oriented correctly before you screw the top on.

vincejames

XS650 Addict

No do not glue them.

Look ... place a drinking a straw in a glass of milk and suck the milk up to the top of the straw. If you place your finger on the top of the straw the milk stays where it is ....why is that? It is because in order for the milk to drop something (air) must take the place of the milk. But nothing can get into the straw because you've blocked the top off with your finger.

However if you lift your finger off the top of the straw slightly the air rushes in allowing the milk to drop. That is the principle.

Now the Mikuni carb has a small hole in the slide which allows a very small amount of air to move from above the diaphram to below and visa versa. This tiny hole regulates how quickly the slides moves up and down which in turn regulates the amount of fuel drawn through the needle jet from the fuel bowl.

The air leak is probably absolutely miniscule ...much less than the size of the hole in a drinking straw . By smearing vasoline around the edge of the diaphram it can prevent tiny air leaks from slight imperfections on the carb body or cap. You shouldn't need to put anything on your new diaphrams if they have been fitted properly.

Got it!

vincejames

XS650 Addict

I think some put a dab of Super Glue between the slide and diaphragm so they don't twist in one anther. I don't think the JBMs have a locating tab on their outer edge like the originals did. You just have to get the slide oriented correctly before you screw the top on.

Correct there is not a locating tab

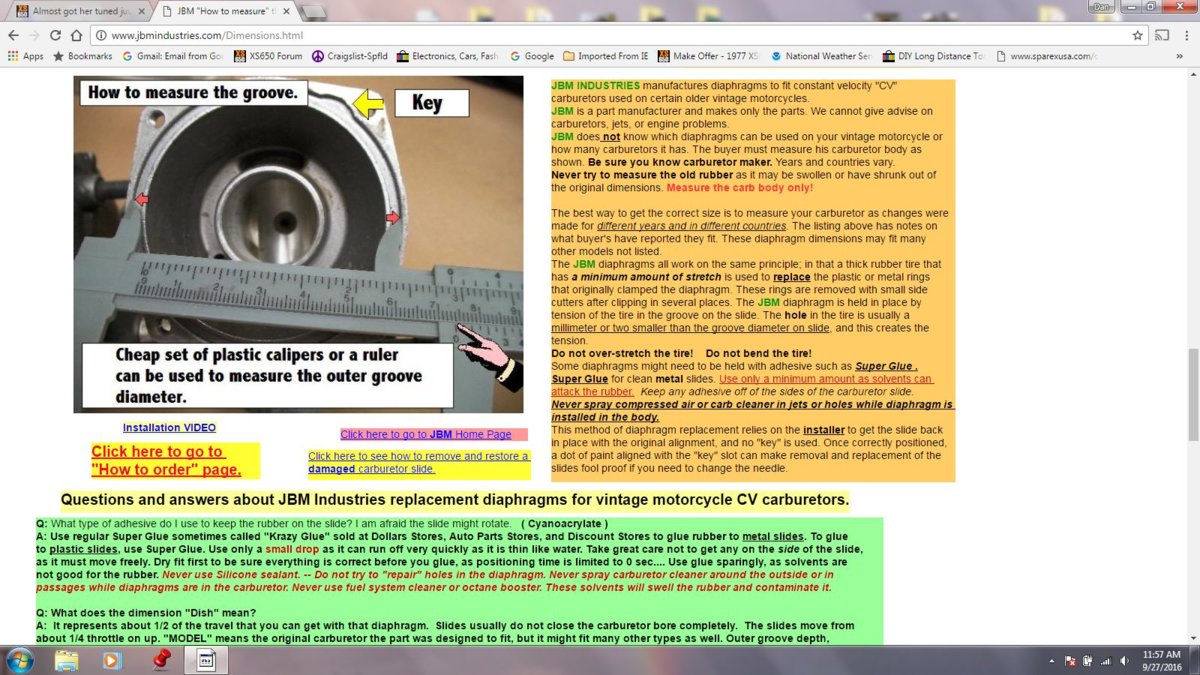

Ok this is from the JBM web site Vince. I'll leave it up to you to decide who is blowing smoke your way.

amazing ....all the hard work is done already but now everyone and his Mother wants to have some imput

As 5twins says on the original diaphragms there is a tab on the edge to help you get the slide facing the right way when you put them back in the carbs.

The little hole in the bottom of the slide must face towards the engine . Do you remember checking this on both your slides ?

just ignore weekendrider.... he is only here to wind me up and to try and take credit for someone elses hard work as usual.

As 5twins says on the original diaphragms there is a tab on the edge to help you get the slide facing the right way when you put them back in the carbs.

The little hole in the bottom of the slide must face towards the engine . Do you remember checking this on both your slides ?

just ignore weekendrider.... he is only here to wind me up and to try and take credit for someone elses hard work as usual.

My my p-nut brave enough to make snarky statements, but then you play the bigger man by ignoring others? You can't ignore them before you make your snide comments? Hit and run poster, eh? And you and you alone have been with him and had his back huh. You lucky you don't break an arm patting yourself on the back.

I'll again ask why can you not raise the slides fully with the vent hole covered? I say that is .

.

@ Vince when you lock down the diaphragm between between the cover and the top of the carb body (regardless if it has a tab or not) the slide can still rotate. That is the reason JBM suggests the super glue. Others in the past have found finger nail polish works as well.

I'll again ask why can you not raise the slides fully with the vent hole covered? I say that is

.

.@ Vince when you lock down the diaphragm between between the cover and the top of the carb body (regardless if it has a tab or not) the slide can still rotate. That is the reason JBM suggests the super glue. Others in the past have found finger nail polish works as well.

vincejames

XS650 Addict

amazing ....all the hard work is done already but now everyone and his Mother wants to have some imput

As 5twins says on the original diaphragms there is a tab on the edge to help you get the slide facing the right way when you put them back in the carbs.

The little hole in the bottom of the slide must face towards the engine . Do you remember checking this on both your slides ?

just ignore weekendrider.... he is only here to wind me up and to try and take credit for someone elses hard work as usual.

yes, I made sure that it the slides were aligned. I read the instructions from the JBM site before I installed.

Can someone please answer my question? What should the slide be doing when held up and the hole is covered? Should it lower very slowly, or not at all? If the case is not at all then I most certainly have a problem...

Thanks - Vince

vincejames

XS650 Addict

And let me state something that might help you all. The JBM diaphragms are actually cut by the manufacturer a tiny bit larger so that when you put the cap back in it's place, after screwing the bolts down, the cap SHOULD help keep it in place due to it's larger size and thickness. In some cases, yes some may have to super glue it down. In some other cases no. What I most certainly am worried about is the seal, which could may or may not be compromised by the larger size of the larger JBM diaphragm.

You don't Super Glue the outer edge to the carb body, you do the inner ring to the slide. The top, once screwed down, is more than enough to keep the diaphragm from turning in the carb body. I answered your question about slide drop in post 35.

vincejames

XS650 Addict

You don't Super Glue the outer edge to the carb body, you do the inner ring to the slide. The top, once screwed down, is more than enough to keep the diaphragm from turning in the carb body. I answered your question about slide drop in post 35.

Maybe a visual will help?

Attachments

vincejames

XS650 Addict

Yes, there, but with the diaphragm mounted in it's proper spot, not pried half off like that. Super Glue works quick. You want to make sure the diaphragm is exactly where it has to be before applying the glue.

Here's a vid of my carbs doing the drop test... sorry for the shaky image...but this should give you an idea of what it should do when you hold over the hole after you've raised the slide.

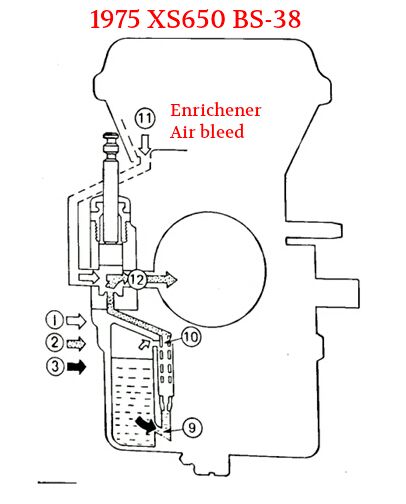

The bottom side of the diaphragm is the atmospheric side, connected to the intake's 'moon' vent. The choke (enrichner) air inlet is also connected to this chamber. If the choke is left on (or doesn't seal properly, the slide will drop rapidly during the 'slide drop' test.

More tips on the JBMindustries diaphragms here:

http://www.xs650.com/threads/jbm-industry.45107/

More tips on the JBMindustries diaphragms here:

http://www.xs650.com/threads/jbm-industry.45107/

vincejames

XS650 Addict

there is your problem right there !

great vid by the way.

Your diaphrams are not sealing somewhere. I had a similar problem and couldn't afford new diaphrams so I smeared vasoline around the edge of the diaphrams where they sit in the lip and a little on the covers and now they are perfect.

The reason that your engine is bogging or going flat off idle is because when you twist the throttle open your slides are leaping up the slide well which is creating a huge immediate low pressure in the venturi. This means your engine cannot draw the extra fuel it needs .

You must hold your thumb or finger over the top vents when the slides are raised up before testing the diaphrams for leaks. (thanks 5Twins)

If your slides do not stay up then you have a leak somewhere either round the edge or at the centre

I don't mean to challenge your expertise because I'm sure it is more superior than mine, I just feel that my diaphragms aren't the problem. I believe that they are in great shape and are functioning exactly the way they should be. Maybe, some better placement with the use of super and/or vaseline might be need, but other than that they are fine... see attached.

Towards the end of the video there is a more clear picture (not that easy to do everything while holding a camera

I'm resorting back to the issue of tuning and adjusting my pilot jet. Thanks for the help though!

Attachments

Last edited:

Your video is set to private? I can't view it anyway.

Similar threads

- Replies

- 35

- Views

- 2K