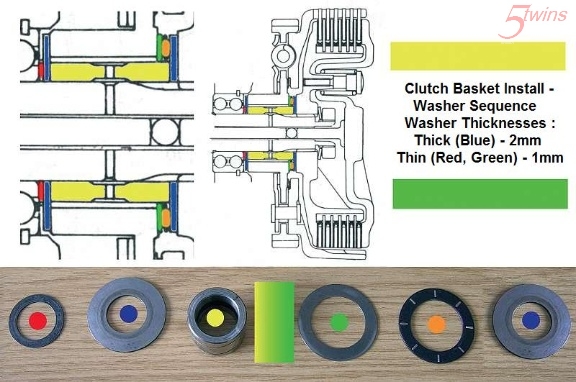

The only thing I can think of that would make the clutch come out too far and rub the cover would be an extra washer in the spacer washer sequence somewhere. I see you have the updated needle bearing. That comes with a new thin thrust washer. You didn't happen to add that new one and leave the original in there too, did you?

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

On the road again at 40.............the bike that is

Thanks for all the suggestions 2M.

I will run through all these tests and report back.

Thank you again!

Of course. I knew you could bring some clarity.The only time when the pressure plate gets close to the cover is when it's displaced outward, during disengagement. Your tic sound occurs anyways.

I'm good on that one. It's back on the kickstart shaft.. I remembered reading this tip of yours elsewhere.Just an FYI, the smaller thin washer that goes on first, against the mainshaft bearing, behind the clutch, is the same p/n spacing washer that goes on the kickstart shaft, often lost because it sticks to the kickstart bushing in the cover.

I will run through all these tests and report back.

Thank you again!

Unfortunately no 5twins. Just the 1mm thrust washer and the 2mm needle bearing.

Hmmmm....I wonder what would happen if you simply installed TWO gaskets on that case cover Robin?

There is really no oil pressure inside and so if you bonded two gaskets together with Hylomar or something like that and then re-assembled it....you might gain enough to stop the rubbing.

Alternatively (and this is much more radical) - could you take the clutch basket to Terry and see if he could machine a teeny bit off it to prevent rubbing?

...just thinkin'...

There is really no oil pressure inside and so if you bonded two gaskets together with Hylomar or something like that and then re-assembled it....you might gain enough to stop the rubbing.

Alternatively (and this is much more radical) - could you take the clutch basket to Terry and see if he could machine a teeny bit off it to prevent rubbing?

...just thinkin'...

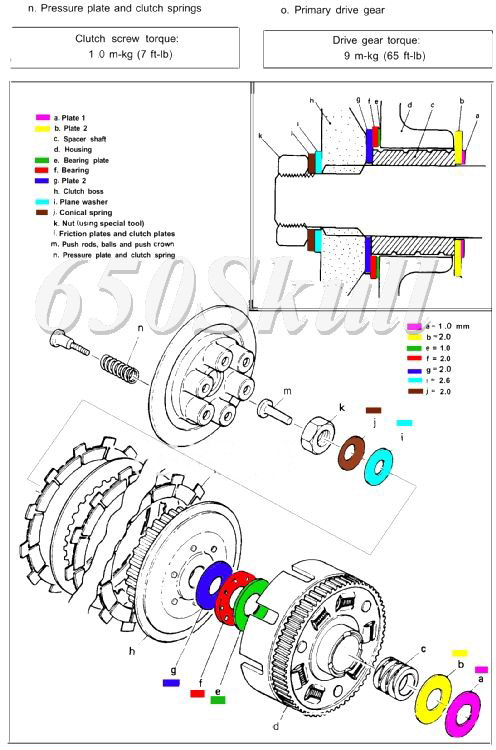

Are you saying you took that 1st smaller thin washer off the clutch and put it on the kick shaft? That wouldn't be right, you need that washer on the clutch shaft to space the housing out away from the engine case. You also say just the 1mm thrust washer and 2mm needle bearing between the inner and outer hub. That wouldn't be right either. There should be a 3rd washer there, a bigger diameter 2mm thick one. But, missing washers in your clutch assembly shouldn't make it rub the outer cover, in fact I would think it would make for more clearance. It could cause rattling because the baskets are loose though. You might want to verify your spacer washer count and assembly sequence is correct .....

The above drawing also nicely illustrates the importance of that 1st small, thin washer in the stack. As you can see, it bears only against the inner race of the bearing mounted in the engine case. This (just barely) spaces the whole rest of the clutch assembly away from the engine case so it doesn't rub.

Another thing that might cause that rubbing on the inside of the cover are some incorrect clutch plates.The early clutch plates were thicker than the later ones, both the steel (1.6mm) and the friction (3.5mm). Later steels were 1.4mm and the frictions were 3mm. Maybe some early plates got thrown in there. Not all of them obviously, but maybe just a couple.

The above drawing also nicely illustrates the importance of that 1st small, thin washer in the stack. As you can see, it bears only against the inner race of the bearing mounted in the engine case. This (just barely) spaces the whole rest of the clutch assembly away from the engine case so it doesn't rub.

Another thing that might cause that rubbing on the inside of the cover are some incorrect clutch plates.The early clutch plates were thicker than the later ones, both the steel (1.6mm) and the friction (3.5mm). Later steels were 1.4mm and the frictions were 3mm. Maybe some early plates got thrown in there. Not all of them obviously, but maybe just a couple.

Eeeeyeahhhh - I'm thinking that this has to be some sort of parts/tolerance stack-up mish-mash thingy (sorry - that is a lot of words).

An assembly like that has SO many parts that all have to be JUST right for the assembly to be JUST right that it wouldn't take too much to mess it up and have a rubbing situation.

What kind of surprises me is that MamaYama made the clutch-case clearance SO tight. I see now reason for why they couldn't have allowed at least 3-4 mm in there. Its not like the XS650 engine was particularly wide (when compared to say...an early CB750K or one of the other UJMs of the early 1970s.

The other thing is that I think that Robin replaced the radial-roller thrust bearing in the clutch assembly with the XS650 Direct/MikesXS part. Now, as I recall it, the XSD part seemed superior because it has more rollers to spread the load (which is better) - but I wonder if it is just a teeny bit "thicker" (i.e. are the rollers a larger diameter) - and could that be the cause of the rubbing?

An assembly like that has SO many parts that all have to be JUST right for the assembly to be JUST right that it wouldn't take too much to mess it up and have a rubbing situation.

What kind of surprises me is that MamaYama made the clutch-case clearance SO tight. I see now reason for why they couldn't have allowed at least 3-4 mm in there. Its not like the XS650 engine was particularly wide (when compared to say...an early CB750K or one of the other UJMs of the early 1970s.

The other thing is that I think that Robin replaced the radial-roller thrust bearing in the clutch assembly with the XS650 Direct/MikesXS part. Now, as I recall it, the XSD part seemed superior because it has more rollers to spread the load (which is better) - but I wonder if it is just a teeny bit "thicker" (i.e. are the rollers a larger diameter) - and could that be the cause of the rubbing?

But they didn't and it is designed to work correctly without jury rigging. My vote keep at it till you find the gremlin and fix that.

If I'm understanding this right...….whatever caused the clearance issue, got worse over time?

Just throwing this in after reading Pete's post. Different gaskets used at different times, different thicknesses?

Scott

Just throwing this in after reading Pete's post. Different gaskets used at different times, different thicknesses?

Scott

Last edited:

But they didn't and it is designed to work correctly without jury rigging. My vote keep at it till you find the gremlin and fix that.

Definitely stick at it.

SOMETHING is going on there and so totally agreed on that point.

Clarify a few points for me Robin.... 1.The tic tic sound. Is it continuous or just a few tics during decel?

2. Is it there with the clutch disengaged and engaged? Or just when you pull the clutch lever in?

2. Is it there with the clutch disengaged and engaged? Or just when you pull the clutch lever in?

First of, let me thank you all for your thoughts, comments and suggestions. Read them a while ago on my phone but waited until I got home to a computer to respond.

No, sorry for the confusion 5twins. I was referring to this kickstart shaft washer that is stuck to the right case cover when you remove it.

I think that's the caution 2M was giving me.

Once again, my apologies, should have mentioned that. Yes there are 3 washers. 'g' is always stuck to the clutch boss isn't it.

I have that pic and also like this one of Skull's.

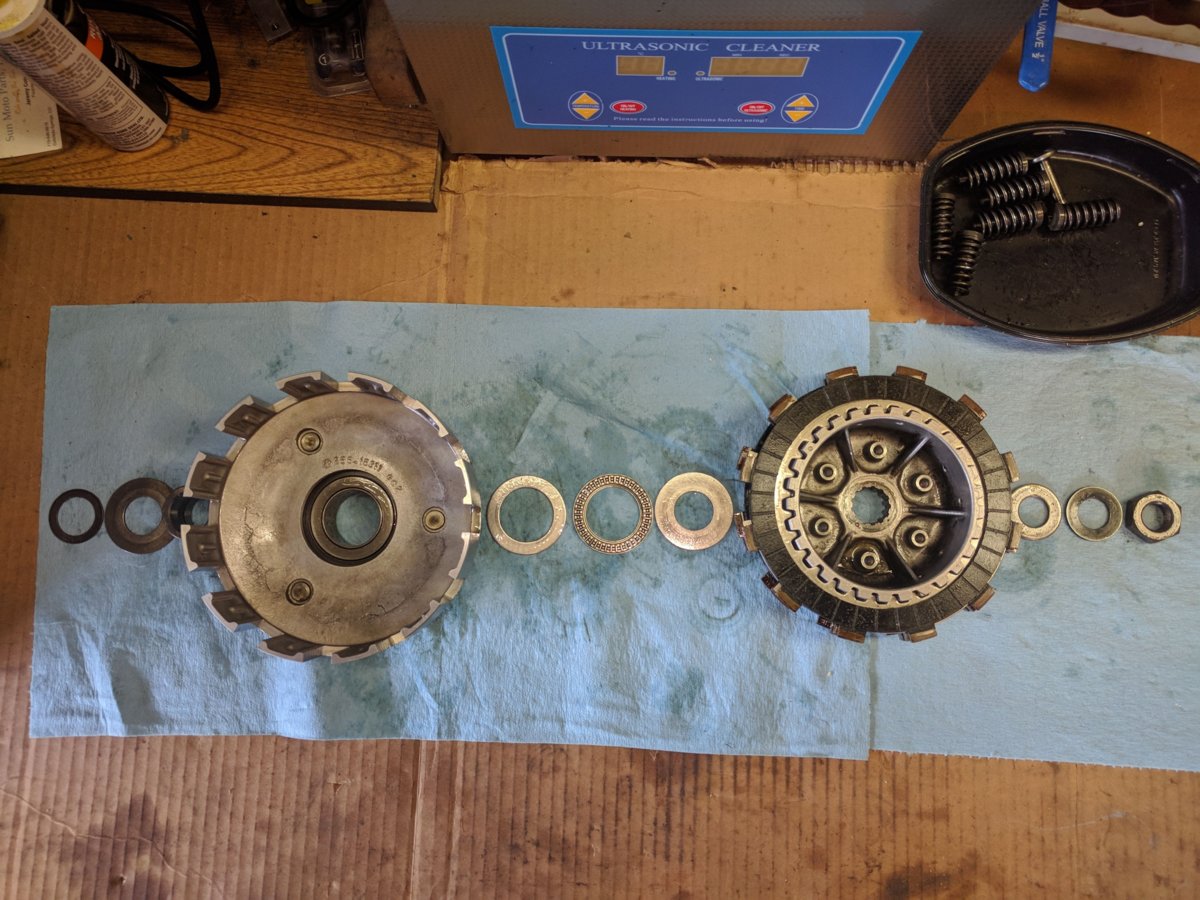

Just took this pic........

Nothing missing, nothing added.

Just went back and checked my thread when I had this apart last November,

http://www.xs650.com/threads/on-the-road-again-at-40-the-bike-that-is.49360/page-22#post-528430

and got this......

Here is the clutch pack.

Fibres are within spes - 2.96 - 2.99mm

Steels are within specs - 1.36mm

Also springs are within specs - 34.6mm

.I will certainly check them all again now.

I'm fairly sure that my ticking noise is due to the pressure plate being too close and making contact with the case cover. More on this in my reply to Jim a few posts from now.

Thank you again for the reply and suggestions.

Are you saying you took that 1st smaller thin washer off the clutch and put it on the kick shaft?

No, sorry for the confusion 5twins. I was referring to this kickstart shaft washer that is stuck to the right case cover when you remove it.

I think that's the caution 2M was giving me.

Once again, my apologies, should have mentioned that. Yes there are 3 washers. 'g' is always stuck to the clutch boss isn't it.

I have that pic and also like this one of Skull's.

Just took this pic........

Nothing missing, nothing added.

Another thing that might cause that rubbing on the inside of the cover are some incorrect clutch plates.The early clutch plates were thicker than the later ones, both the steel (1.6mm) and the friction (3.5mm). Later steels were 1.4mm and the frictions were 3mm. Maybe some early plates got thrown in there. Not all of them obviously, but maybe just a couple.

Just went back and checked my thread when I had this apart last November,

http://www.xs650.com/threads/on-the-road-again-at-40-the-bike-that-is.49360/page-22#post-528430

and got this......

Here is the clutch pack.

Fibres are within spes - 2.96 - 2.99mm

Steels are within specs - 1.36mm

Also springs are within specs - 34.6mm

.I will certainly check them all again now.

I'm fairly sure that my ticking noise is due to the pressure plate being too close and making contact with the case cover. More on this in my reply to Jim a few posts from now.

Thank you again for the reply and suggestions.

I agree Pete.Eeeeyeahhhh - I'm thinking that this has to be some sort of parts/tolerance stack-up mish-mash thingy

But they didn't and it is designed to work correctly without jury rigging. My vote keep at it till you find the gremlin and fix that.

I absolutely agree WER. I doubt I would be able to figure this out on my own but 'collectively' with all your guys help......we'll solve it!

If I'm understanding this right...….whatever caused the clearance issue, got worse over time?

Just throwing this in after reading Pete's post. Different gaskets used at different times, different thicknesses?

Scott

Well Scott, back in 1990 when the mechanic who replaced the shift shaft didn't have things seated properly somehow, and the clutch wasn't disengaging, a neighbour and I pulled the right case off, saw those marks where the pressure plate had rubbing on the case and did 'something' that fixed it. That was 28 years ago and I can't for the life of me remember what. From then until 2008, when I took it off the road I never had any clutch problems.

Last year, there were no problems for 2400 miles. I took it all apart to do the starter gear repair last November, and only put a few miles on it then until I did the top end rebuild, finished and back on the road in May of the this year..

These increased gouge marks on the case are since Nov. 2017. So once again whatever had done this before is doing it again.

This ticking noise is a new one. I don't ever recall hearing anything like this or would have been concerned and investigated.

I am now using a Yamaha OEM gasket. Maybe it is a little thinner than what was on there previously? If so, that is now allowing this problem to reappear and causing us to look for the root of the problem.

Clarify a few points for me Robin.... 1.The tic tic sound. Is it continuous or just a few tics during decel?

2. Is it there with the clutch disengaged and engaged? Or just when you pull the clutch lever in?

Hey Jim, here are the results of the tests that 2M had given me,back here.......

http://www.xs650.com/threads/on-the-road-again-at-40-the-bike-that-is.49360/page-51#post-552230

Ok, got some tests done 2M.

1. This one was interesting and we noticed it as we were just leaning the bike over prior to revving.

The noise appeared and got louder when tipping right, no noise tipping left.

2. When doing the rev thing, same results. Revs drop, louder on right lean, no noise on left lean.

3. Pull in the clutch lever, do the rev thing, noise is louder on the right as revs drop, no noise on the left lean.

4. Put in 1st and then 2nd. Clutch disengaged, do the rev thing, noise is there as revs drop. Seemed louder in 1st than in 2nd though.

With the bike upright,the noise appears on decel.

With the bike leaned to the right, tic tic is there constantly without any RPM increase. No noise when tipped left.

This seems to be pretty consistent.

I have to think that this is confirming that my noise is in fact the pressure plate rattling on the inside of the case. When it's tipped right it's close enough to rattle all the time. When it's tipped left it's moved far enough away to no longer make contact.

Of course the million dollar question is how could this happen if everything is assembled correctly.

An extra washer or one too thick in the wrong place could do this as could 5twins idea re: plate thickness.

Wanted to respond to all of you, have to run a couple of errands for honey so I'll go through all 2M's tests and snoop around in there a little more later this aft.

Thank you all once again!

If the pressure plate was causing the noise, it would only do it when you disengage the clutch. Think of it this way... if the plate was ticking against the side cover when it's engaged.... it would be grinding like all hell when you pulled the lever in and pushed the pressure plate harder into the cover.

It almost sounds like, once all assembled, the clutch basket is loose on the shaft, able to slide in and out a little bit. When you tilt the bike right, the basket slides out and rubs the cover. But I don't know what could cause that. With the clutch completely assembled, can you slide it in and out at all on it's shaft?

Ah, ya, so much for my brilliant ideas Jim. Going stop guessing at stuff. I'm really curious though why this occurs on a right lean and disappears on a left?

And, why it has been rubbing on the inside of the case off and on.

And, why it has been rubbing on the inside of the case off and on.

Huh, good idea 5twins. I'll check that when I get home.

Similar threads

- Replies

- 15

- Views

- 2K