Simebone

If it's not broke, wait week.

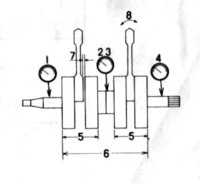

Measurements updated to prior post:

Interesting ! the rings on the right cylinder are almost lined up if they came out of the cylinder that way that's probably SOME of the problem!

it looks to me as if those rings are passing compression, or at least some you can tell by the dark streaks down the piston toward the skirt.( this is a Matter of interpretation others will have different ideas on the coloration ,like too hot on one side)

I think I would measure the bore in a bunch of different places from top to bottom and write it down... see if there is tapered or oval to the cylinders.... it may need re-bored if so.

...I have also had excellent luck with copper-coat on head gaskets... even on warped heads I knew were bad and needed shaved !

....

do the rings stick to the piston in any places ? with all the carbon you had in the top end it's almost a given that the ring grooves will need cleaned too ( piston ring groove cleaner) that in it self could cure the low compression on the one side.

.....Also...stuff some clean rags under the piston to keep out things from falling in the bottom end !!!!! that's a MUST !!!!!!!.... piston pin clips can fall in there and you'll play hell getting them out again !

.....

Bob.......