This is an issue that has caused a lot of guys problems over the years.

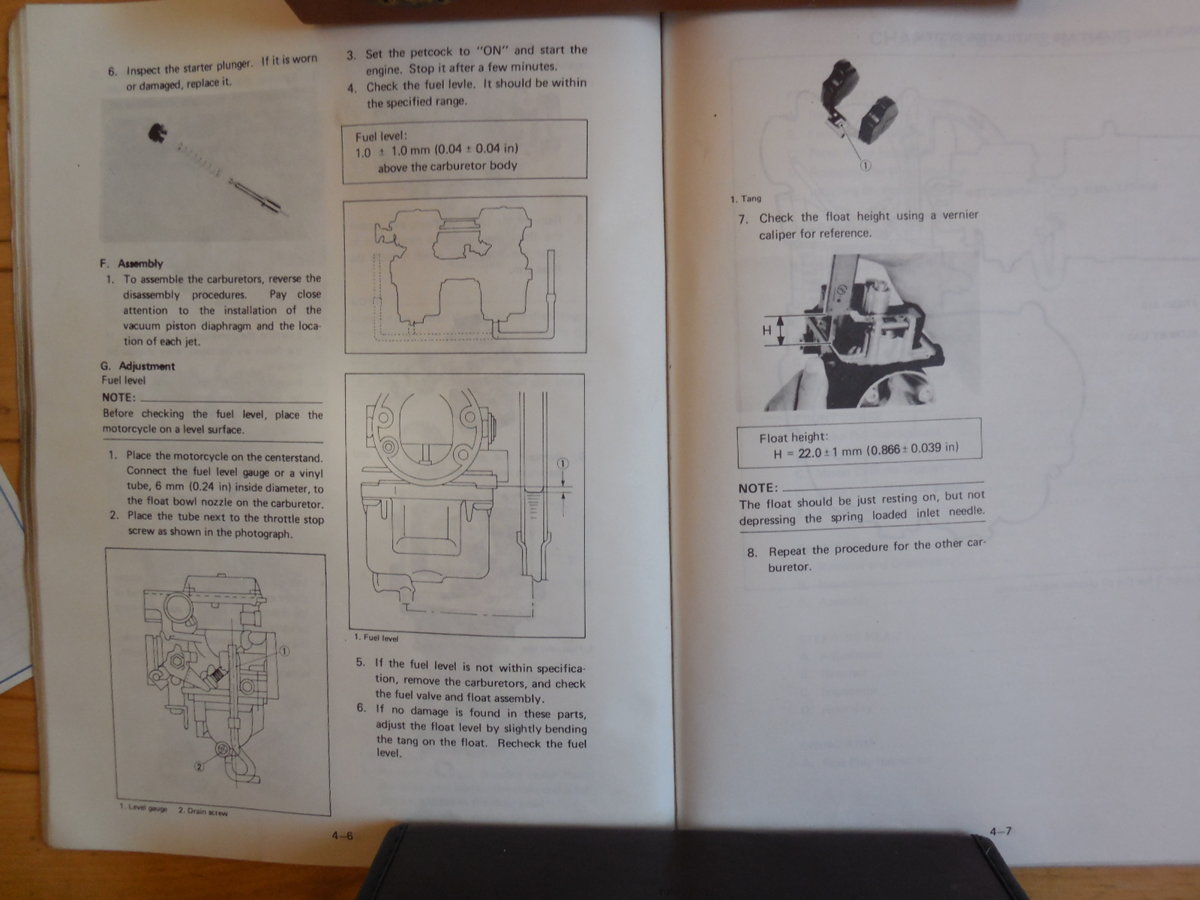

The brass float is height setting point is quite plain to see in the manual picture, the plastic float picture?, not so much.

The pic is fuzzy, angled, gray enough that which surface they use for 22mm is not clear.

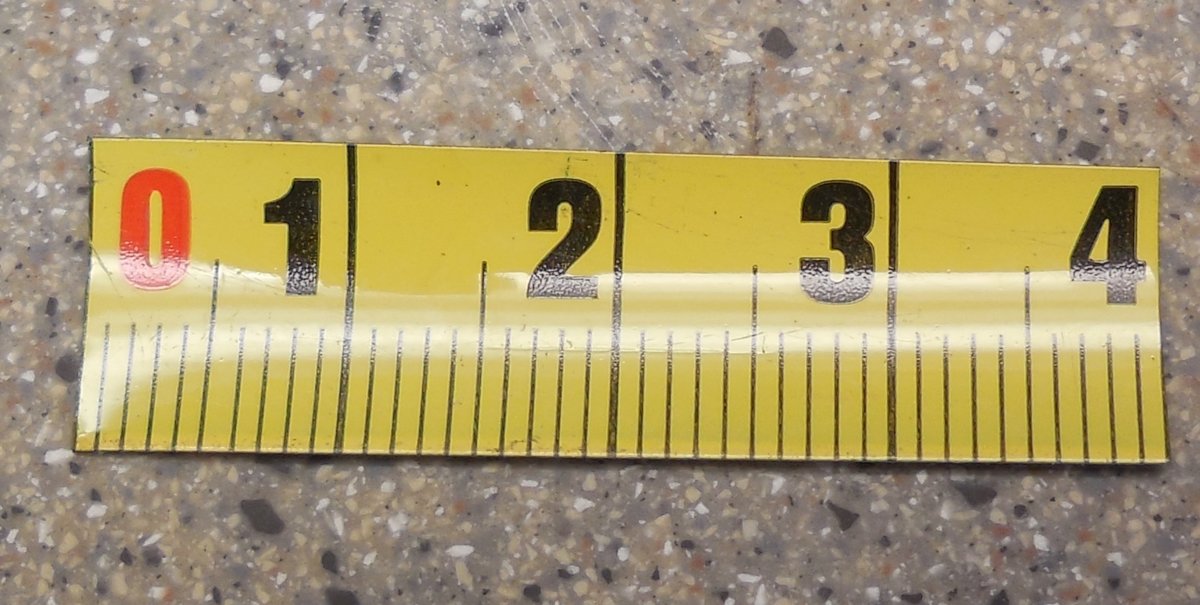

I've been successfully using the flat part of the float that is the same level as the stainless bracket/tang. not the lower part after the notch that curves down further out. This results in a float that sits roughly parallel to the carb flange when set at 22mm. Some pics of my method, a selection of plastic floats from the bins mostly with factory??? tang bend.

Let the debate rage. Hyde PM'd me with some questions about this so figured a thread is in order.

The brass float is height setting point is quite plain to see in the manual picture, the plastic float picture?, not so much.

The pic is fuzzy, angled, gray enough that which surface they use for 22mm is not clear.

I've been successfully using the flat part of the float that is the same level as the stainless bracket/tang. not the lower part after the notch that curves down further out. This results in a float that sits roughly parallel to the carb flange when set at 22mm. Some pics of my method, a selection of plastic floats from the bins mostly with factory??? tang bend.

Let the debate rage. Hyde PM'd me with some questions about this so figured a thread is in order.

Attachments

Last edited:

I suspect there are some ignition issues as I sort out this bike. More to follow.

I suspect there are some ignition issues as I sort out this bike. More to follow.