cbuckle

XS650 Enthusiast

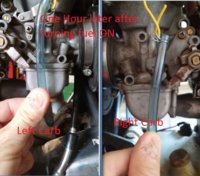

Another carb question unfortunately. I recently bought carb kit (http://www.xs650direct.com/products-36.html) for my 74’ BS38 carbs Part #48-1919.

Can someone please tell me if the ‘Float needle assy 2.5’ is correct for my carbs. As before my bike stinks of fuel, and I can see the odd time fuel coming out the overflow. Did a lot of reading. Floats are both level and set to 24mm. Bike leaks whether on center or side stand.

If these are not quality float valves can someone just tell me that and where in Canada I should be buying these. Also rubber tips or not

I keep on returning to the Addendum on page 8 of the carb guide http://www.amckayltd.com/carbguide.pdf but don’t understand if this is a design flaw of the carb, or my problem

I will be doing the M8-1.0 grease fitting/ clear tub test to check my fuel level shortly

Sorry for yet another carb question, thanks

Can someone please tell me if the ‘Float needle assy 2.5’ is correct for my carbs. As before my bike stinks of fuel, and I can see the odd time fuel coming out the overflow. Did a lot of reading. Floats are both level and set to 24mm. Bike leaks whether on center or side stand.

If these are not quality float valves can someone just tell me that and where in Canada I should be buying these. Also rubber tips or not

I keep on returning to the Addendum on page 8 of the carb guide http://www.amckayltd.com/carbguide.pdf but don’t understand if this is a design flaw of the carb, or my problem

I will be doing the M8-1.0 grease fitting/ clear tub test to check my fuel level shortly

Sorry for yet another carb question, thanks