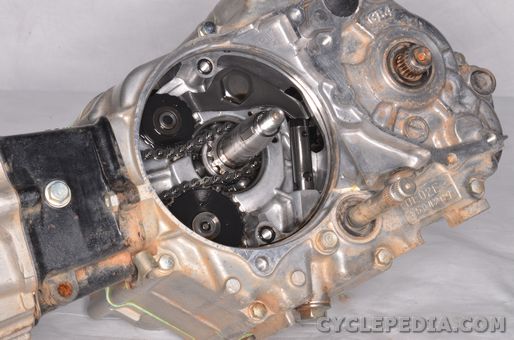

I would say two and mount them rigidly, roughly as far apart as the ends of the stock guide. That is off the top of my head, I'd have to get my fingers in a disassembled motor to say for sure. Honda CRF70 cam chain guide sprockets:

EDIT: Clone engine cam tensioner sprocket, $9.00 each. Has a 10mm bore.

http://avantispowersports.com/shop/viewitem.php?productid=268

That's what I want front and rear. How do I make it work?