YL82

Perpetual Restorationist

Cases split today - I may post a "here's how I did it" video later (See Post #6 of this Thread).

What's happened to the 2 studs (front ones) that are nasty looking? Are these easy to replace and will I be able to find replacements?

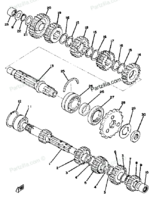

What's the proper tool to remove the 3 circlips (#16 in diagram) on the transmission Drive Axle (Output Shaft)? I've got snap ring pliers, but they seem more suited to the rings that have holes in them to grab onto. I got one circlip off with a screwdriver, but I didn't do it any favor.

What's happened to the 2 studs (front ones) that are nasty looking? Are these easy to replace and will I be able to find replacements?

What's the proper tool to remove the 3 circlips (#16 in diagram) on the transmission Drive Axle (Output Shaft)? I've got snap ring pliers, but they seem more suited to the rings that have holes in them to grab onto. I got one circlip off with a screwdriver, but I didn't do it any favor.

Attachments

Last edited: