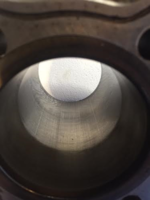

I am in the process of tearing down my top end due to a defective cam chain guide. I have owned this bike for several years but it has never run since I've owned it. I have decent mechanical skills, but not much knowledge or experience in rebuilding engines and have limited hand tools. The motor has about 18k on the clock. Since I have it apart I am going to freshen it up so I know what I am working with. The Pistons and head cleaned up pretty well. My question is, how do I tell if I can just hone and re-ring, or if I need to bore and go oversize? Should my local Machine shop be able to advise if I take the cylinder and Pistons in? I considered sending it to Hoos Racing to bore but thought that might be a waste of money if I can get by on just honing and rings. I have a little money to work with but on a tight budget.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

Cylinder boring question

- Thread starter willis

- Start date

-

- Tags

- cylinder boring