Mharrington

XS650 Addict

Actually I thinks it will be tracker ish. Got myself a 1980 Special 2 with 22,000 miles. It has a 1975 tank and side covers. I have little money to spend! The bike is overall in very good condition. All stock- I bought from a guy who let it sit for 5 years. I got it running in October and the cranking psi was 148 each cylinder- warm with throttle wide open. No smoke from exhaust and no oil in the airbox. Plugs looked kind of lean (will replace throttle shaft seals). My plan is tracker seat which I already purchased from Gopher Glass, new seals as the engine was a leaker, a new head gasket (leaks at head AND engine is already out to clean and paint so Ill do copper washers and a head gasket) Questions:

The oem rear wheel is a sixteen inch. I have an older 650 18 inch that came with the bike but its a shouldered aluminum unit (stock is chrome steel) Is it a big no no to run a 16 rear on such a street tracker? If I run the alum shouldered 18 it will not match the steel chrome front. I do not care about this but want opinions. I plan on white lettered Bridgestone tires as inspired by a member bike here.

The bike displayed no smoke from the exhaust. Should I go ahead and put in new valve seals?

After a new clutch cable, adjusting and lubing the mechanism the clutch pulls nice/easy and works great. Should I replace the bushing?

Looks like the 10 pc seal kit from Mikes XS is the way to go?

I will inspect pickup sump screen. If its bad is the Mikes XS the new one to use? Do the shield mod on a new one?

Buy and entire gasket kit from Mikes instead of the single head gasket piece?

Looks like the 16 inch rear wheels occasionally sell for a good $$ on sleazebay- I could fund my parts by selling the 16 incher.

Thank you gentleman!

Seat resting on bike

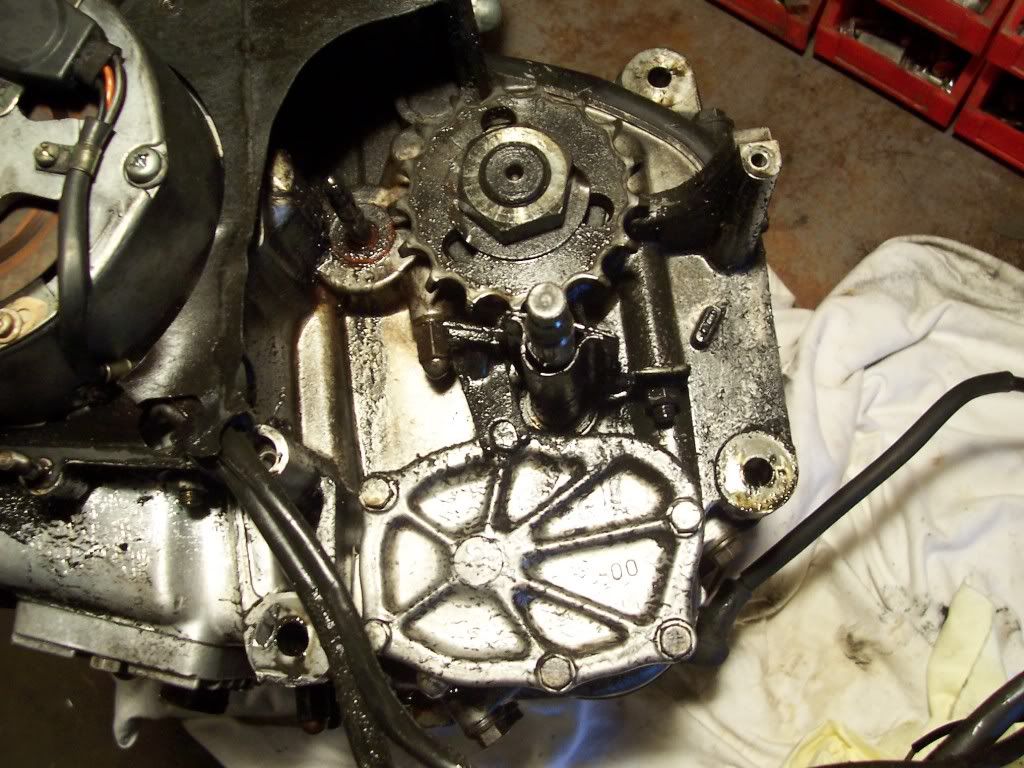

Oil leaks

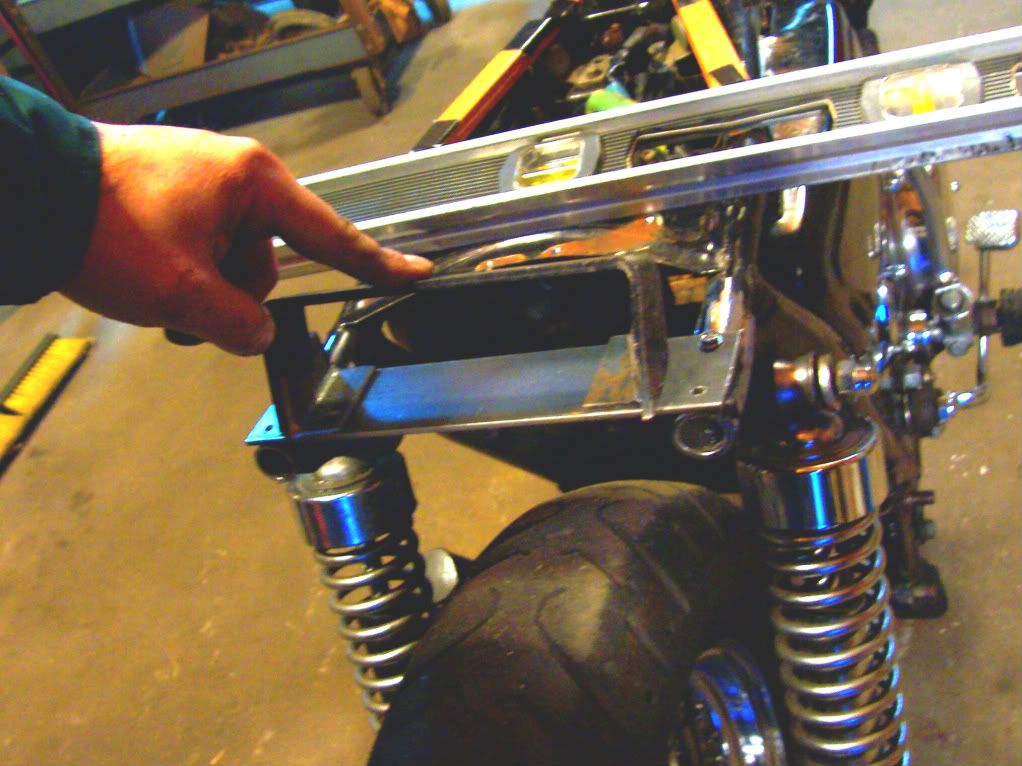

Home made bracket (I do not know how to weld!)

Engine out

Gotta clean the frame spotless to paint.

The oem rear wheel is a sixteen inch. I have an older 650 18 inch that came with the bike but its a shouldered aluminum unit (stock is chrome steel) Is it a big no no to run a 16 rear on such a street tracker? If I run the alum shouldered 18 it will not match the steel chrome front. I do not care about this but want opinions. I plan on white lettered Bridgestone tires as inspired by a member bike here.

The bike displayed no smoke from the exhaust. Should I go ahead and put in new valve seals?

After a new clutch cable, adjusting and lubing the mechanism the clutch pulls nice/easy and works great. Should I replace the bushing?

Looks like the 10 pc seal kit from Mikes XS is the way to go?

I will inspect pickup sump screen. If its bad is the Mikes XS the new one to use? Do the shield mod on a new one?

Buy and entire gasket kit from Mikes instead of the single head gasket piece?

Looks like the 16 inch rear wheels occasionally sell for a good $$ on sleazebay- I could fund my parts by selling the 16 incher.

Thank you gentleman!

Seat resting on bike

Oil leaks

Home made bracket (I do not know how to weld!)

Engine out

Gotta clean the frame spotless to paint.