I have pondered the merits of owning a milling machine but cannot justify the cost as I can do most very small milling projects on my lathe. So having decided a mill is not for me, I have spent the last 5 months slowly modifying my crappy bench drill to a mill/drill. I had to rebore the quill to take a good dual race angular bearing and make a new chuck as the B16 drill chuck was not coaxial with the drive mechanism:

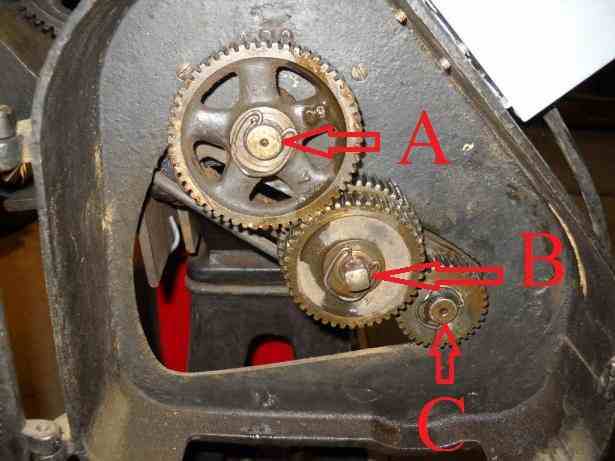

Yesterday I finished the final job, a cut depth fine adjuster:

The final beast:

I have had a good play on it and with the correct cutter it does an excellent good on Brass and Aluminum with cut depths up to 3mm. I have no intention of milling steel because as cute as my mill is, it lacks sufficient metal to take out the flexibility. I imagine it will groan and vibrate on steel but may be ok for cast iron (steam engine cylinders). My total cost for the conversion was approximately £50 with £20 of that going on the cheap Chinese compound slide to allow me to work on larger items than my lathe's milling attachment can accommodate.

Moral of the story: A cheap bench drill will never make a high precision milling machine, that is why it is called a cheap bench drill. But it will satisfy my current needs working to 0.1mm or thereabouts.

Yesterday I finished the final job, a cut depth fine adjuster:

The final beast:

I have had a good play on it and with the correct cutter it does an excellent good on Brass and Aluminum with cut depths up to 3mm. I have no intention of milling steel because as cute as my mill is, it lacks sufficient metal to take out the flexibility. I imagine it will groan and vibrate on steel but may be ok for cast iron (steam engine cylinders). My total cost for the conversion was approximately £50 with £20 of that going on the cheap Chinese compound slide to allow me to work on larger items than my lathe's milling attachment can accommodate.

Moral of the story: A cheap bench drill will never make a high precision milling machine, that is why it is called a cheap bench drill. But it will satisfy my current needs working to 0.1mm or thereabouts.

Last edited: