Question regarding CAM positioning, left/right. What is the correct positioning?

I see one youtuber align the cam bearings to a face within the head, and states that the CAMs on the XS650 do float a bit (left / right). A couple of other youtubers don't really address it, but after watching the videos several times it appears to be positioned with "loose tolerance". Checking all the manuals I have for the XS650 only one addresses this. It's has conflicting / unclear information stating the bearings should be positioned as far inward as possible. Even goes so far as to use a threads-all rod to pull the bearings up against the CAM faces during assembly.

If the bearings are up against the CAM, I would assume we could measure left and right positions off the head to the bearing face after positioning - of course - "everything" has a tolerance...

I unfortunately, torqued everything down, then measured it... When will I learn! Considering that everything has tolerance, ahem...

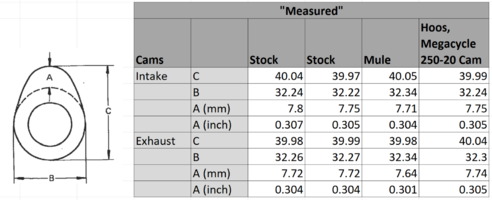

Below, left and right sides were measured in 6 locations each. The rocker cover is tighter than the head.

CAM Position per Rocker cover measurements, rightward Bias: .0018"

CAM Position per Head measurements, rightward Bias: .0025"

Average position rightward bias: .0022"

Is this acceptable?