-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

MIG Welder Suggestions.

- Thread starter Jim

- Start date

I love my 205ds Yeswelder.

Customer support for me has been top notch.

Only a hobby welder but I have had zero issues.

I use all 3 processes (stick/mig/tig) I also use gas. I upgraded the ground clamp.

Not used every day, but used regularly.

Yes it's chinesium and true enough you have to have a bit of patience with the duty cycle but the 240 makes it a bit more palatable.

There are many better , higher quality units available no doubt. But hard to beat this unit bang for the buck.

Just my 2 cents.

Customer support for me has been top notch.

Only a hobby welder but I have had zero issues.

I use all 3 processes (stick/mig/tig) I also use gas. I upgraded the ground clamp.

Not used every day, but used regularly.

Yes it's chinesium and true enough you have to have a bit of patience with the duty cycle but the 240 makes it a bit more palatable.

There are many better , higher quality units available no doubt. But hard to beat this unit bang for the buck.

Just my 2 cents.

Nothing on the website.... you know how big a spool it'll hold?I love my 205ds Yeswelder.

Customer support for me has been top notch.

Only a hobby welder but I have had zero issues.

I use all 3 processes (stick/mig/tig) I also use gas. I upgraded the ground clamp.

Not used every day, but used regularly.

Yes it's chinesium and true enough you have to have a bit of patience with the duty cycle but the 240 makes it a bit more palatable.

There are many better , higher quality units available no doubt. But hard to beat this unit bang for the buck.

Just my 2 cents.

I have only ran the small (4"/2lb?) spools but I am certain that it will run the large (8"/10lb?) spools as well. You would get a great feel for their customer service if you called with any and all questions. I've never had to wait long like so many places force you to do. Not certain of their hours off the top of my head. I ordered mine direct from them which I highly recommend. They also provided the best price when I was shopping for one.

What are y'alls thoughts on this one? 4.5 stars out of 1600 ratings borders on unbelievable. Coupon for $30 off gets it to $330 + tax. Almost sounds too good to be true. I already have a good TIG welder, so I don't really need that added functionality... whatever.

https://www.amazon.com/YESWELDER-Di...2a5-9370-9352fb6590f7&pd_rd_i=B07TVCWDGW&th=1

View attachment 246305

The upside… you buy it, test it hard and if it blows just get a refund.

Probably won’t even have to box it up. I always feel weird dropping unboxed items off at the ups store for returns but they ask for it that way.

I am not going to make 69....All you old guys scare me, won't be 69 til next April.

Duty cycle is what you pay for. If your only going to do 2 min welds then anything that will do 30% at 100 amps will do.

still that is shit. I went real cheap before I understood duty cycle. I was also warned the welder had an aluminium core/windings. Thought, I was only building a canopy out of 1" X 2.5mm box steel so each weld was only an inch long, what could go wrong.

If I was lucky I would get one run done before I had to wait 5 min for the welder to cool. Took a while, but finally got it built then the weder went to the tip.

Bought a Cigweld weldskill inverter 170amp single phase arc welder. Weighs 6.5 kg.

Duty cycle 110A @ 60%, 85A @ 100%.

After I bought it I tried a butt weld, stick 2.5mm material 1.5mm at 30A. Smooth, (min splatter), I couldn't believe it didn't blow holes and the penetration was good.

That add has no, ( I couldn't find it), info on duty cycle. Without that info you get what your paying for. It sounds like it could be problematic going off Bluze's comment about "having to have patience with the duty cycle". A reasonable 200A welder should run 80 -100% duty @100A.

I can burn a whole rod without cut out. Not that I ever do that long of a run, did try once.

Had to laugh at your comment, the more you look, the decision

gets clouded. I find the same thing.

still that is shit. I went real cheap before I understood duty cycle. I was also warned the welder had an aluminium core/windings. Thought, I was only building a canopy out of 1" X 2.5mm box steel so each weld was only an inch long, what could go wrong.

If I was lucky I would get one run done before I had to wait 5 min for the welder to cool. Took a while, but finally got it built then the weder went to the tip.

Bought a Cigweld weldskill inverter 170amp single phase arc welder. Weighs 6.5 kg.

Duty cycle 110A @ 60%, 85A @ 100%.

After I bought it I tried a butt weld, stick 2.5mm material 1.5mm at 30A. Smooth, (min splatter), I couldn't believe it didn't blow holes and the penetration was good.

That add has no, ( I couldn't find it), info on duty cycle. Without that info you get what your paying for. It sounds like it could be problematic going off Bluze's comment about "having to have patience with the duty cycle". A reasonable 200A welder should run 80 -100% duty @100A.

I can burn a whole rod without cut out. Not that I ever do that long of a run, did try once.

Had to laugh at your comment, the more you look, the decision

gets clouded. I find the same thing.

For some reason I can't recall, I initially discounted this little Yeswelder right off the bat. But based on Blues opinion above and several video reviews I've just watched, I'm havin' trouble finding a reason not to grab it. One reviewer even went so far as to pull the cover for a quality check. It looks amazingly robust for Chinese stuff. A few answers I've found....

Gary, yes, it'll take a 10lb spool. Burn away buddy...

Doug, duty cycle is (claimed) 60% at 205A.... 100% at 165A. That's fed from 220, which is how I'll roll. On 110 it's not as good, but still tolerable.

Greg, it's 23lbs

Bluz, the Amazon store is Yeswelder.... which makes sense. A lot of places have their own storefront and also have one on Amazon.... Eastwood comes to mind. Too many people today just go to Amazon and don't shop around.... and a fair number discount Amazon out of hand. Having both your own and an Amazon front doubles your exposure.

At Yeswelder's website, it's $350 with free shipping.

Amazon is $360 with a coupon for $30 off.... so $330 and free shipping with prime. Both charge the same in taxes.

I jus' pulled the trigger at Amazon.... $354 and change

Gary, yes, it'll take a 10lb spool. Burn away buddy...

Doug, duty cycle is (claimed) 60% at 205A.... 100% at 165A. That's fed from 220, which is how I'll roll. On 110 it's not as good, but still tolerable.

Greg, it's 23lbs

Bluz, the Amazon store is Yeswelder.... which makes sense. A lot of places have their own storefront and also have one on Amazon.... Eastwood comes to mind. Too many people today just go to Amazon and don't shop around.... and a fair number discount Amazon out of hand. Having both your own and an Amazon front doubles your exposure.

At Yeswelder's website, it's $350 with free shipping.

Amazon is $360 with a coupon for $30 off.... so $330 and free shipping with prime. Both charge the same in taxes.

I jus' pulled the trigger at Amazon.... $354 and change

Kids these days...All you old guys scare me, won't be 69 til next April.

For some reason I can't recall, I initially discounted this little Yeswelder right off the bat. But based on Blues opinion above and several video reviews I've just watched, I'm havin' trouble finding a reason not to grab it. One reviewer even went so far as to pull the cover for a quality check. It looks amazingly robust for Chinese stuff. A few answers I've found....

Gary, yes, it'll take a 10lb spool. Burn away buddy...

Doug, duty cycle is (claimed) 60% at 205A.... 100% at 165A. That's fed from 220, which is how I'll roll. On 110 it's not as good, but still tolerable.

Greg, it's 23lbs

Bluz, the Amazon store is Yeswelder.... which makes sense. A lot of places have their own storefront and also have one on Amazon.... Eastwood comes to mind. Too many people today just go to Amazon and don't shop around.... and a fair number discount Amazon out of hand. Having both your own and an Amazon front doubles your exposure.

At Yeswelder's website, it's $350 with free shipping.

Amazon is $360 with a coupon for $30 off.... so $330 and free shipping with prime. Both charge the same in taxes.

I jus' pulled the trigger at Amazon.... $354 and change

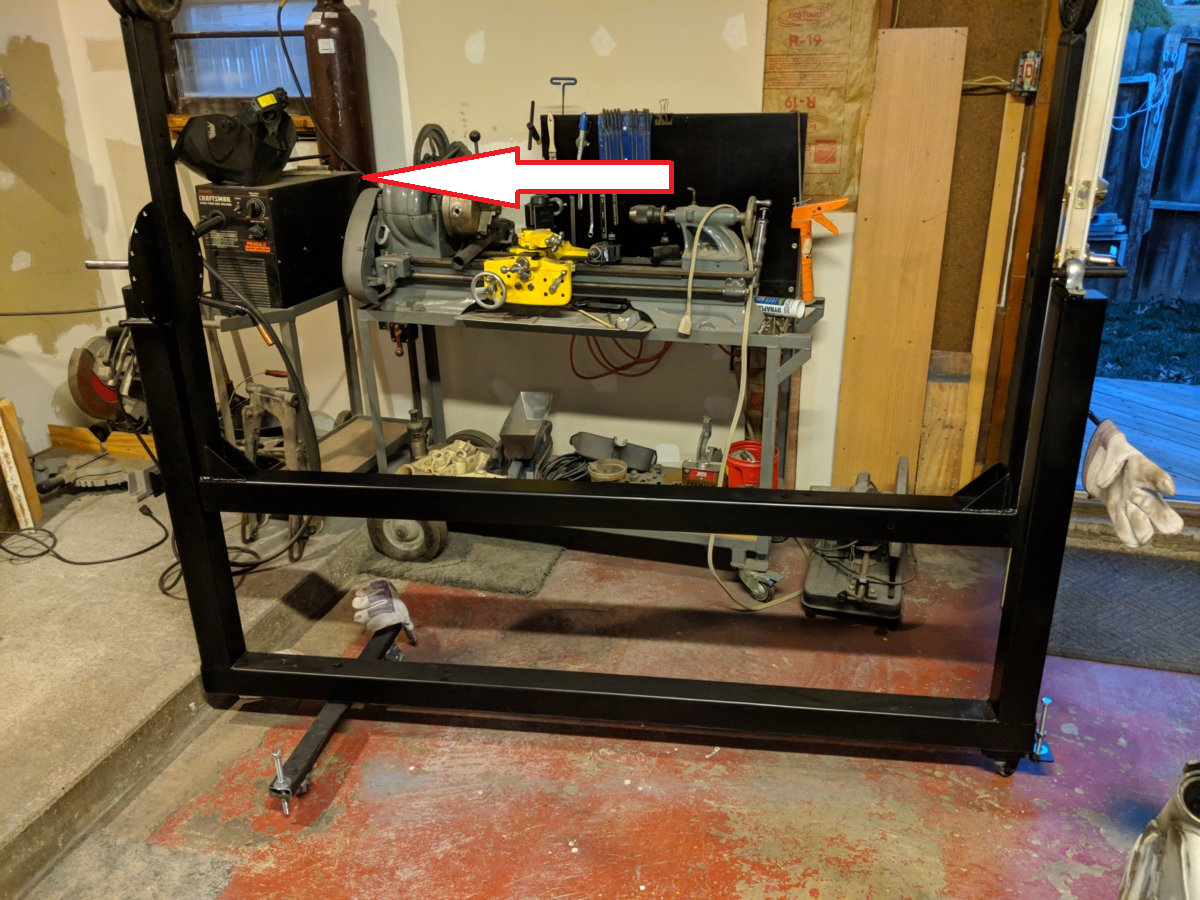

You didn’t mention if a used machine was on the table but I’ve seen some very reasonable  low-use suitcase welders online. I picked this one up a few years back and couldn’t be happier. Accepts gas, uses the large spools and is not too heavy on the roll around cart.lol I I basically got it for free. I had helped a friend that worked at a storage facility and had cleaned out a unit. She gave me several older analog O-scopes since I knew how to set them up. I had been using a cheap HF welder and experienced all the disappointments listed above. Low duty cycle, 15 min cool down period, and wanted to upgrade. Looked on CL and lo and behold a guy was looking to swap his welder for(you guessed it) an O-scope. What are the odds? 12 yrs later still making dimes.

low-use suitcase welders online. I picked this one up a few years back and couldn’t be happier. Accepts gas, uses the large spools and is not too heavy on the roll around cart.lol I I basically got it for free. I had helped a friend that worked at a storage facility and had cleaned out a unit. She gave me several older analog O-scopes since I knew how to set them up. I had been using a cheap HF welder and experienced all the disappointments listed above. Low duty cycle, 15 min cool down period, and wanted to upgrade. Looked on CL and lo and behold a guy was looking to swap his welder for(you guessed it) an O-scope. What are the odds? 12 yrs later still making dimes.

low-use suitcase welders online. I picked this one up a few years back and couldn’t be happier. Accepts gas, uses the large spools and is not too heavy on the roll around cart.lol I I basically got it for free. I had helped a friend that worked at a storage facility and had cleaned out a unit. She gave me several older analog O-scopes since I knew how to set them up. I had been using a cheap HF welder and experienced all the disappointments listed above. Low duty cycle, 15 min cool down period, and wanted to upgrade. Looked on CL and lo and behold a guy was looking to swap his welder for(you guessed it) an O-scope. What are the odds? 12 yrs later still making dimes.

low-use suitcase welders online. I picked this one up a few years back and couldn’t be happier. Accepts gas, uses the large spools and is not too heavy on the roll around cart.lol I I basically got it for free. I had helped a friend that worked at a storage facility and had cleaned out a unit. She gave me several older analog O-scopes since I knew how to set them up. I had been using a cheap HF welder and experienced all the disappointments listed above. Low duty cycle, 15 min cool down period, and wanted to upgrade. Looked on CL and lo and behold a guy was looking to swap his welder for(you guessed it) an O-scope. What are the odds? 12 yrs later still making dimes.So you had me looking, found it for $300?

https://www.amazon.com/YESWELDER-Digital-MIG-205DS-Voltage-Gasless/dp/B0BVFBWRHX/ref=sr_1_1_sspa?crid=1IGEM8F8BKTFL&keywords=yeswelder+mig&qid=1688215828&s=hi&sprefix=yeswelder+mig,tools,117&sr=1-1-spons&sp_csd=d2lkZ2V0TmFtZT1zcF9hdGY&psc=1

Found it: green vs black ability to use an aluminum spool gun.

Spool gun another $190. just over your $500 limit....

https://www.amazon.com/YESWELDER-Digital-MIG-205DS-Voltage-Gasless/dp/B0BVFBWRHX/ref=sr_1_1_sspa?crid=1IGEM8F8BKTFL&keywords=yeswelder+mig&qid=1688215828&s=hi&sprefix=yeswelder+mig,tools,117&sr=1-1-spons&sp_csd=d2lkZ2V0TmFtZT1zcF9hdGY&psc=1

Found it: green vs black ability to use an aluminum spool gun.

Spool gun another $190. just over your $500 limit....

Last edited:

I have the 135 version of that. Bought it as my first welder 30+ years ago. Had to replace the range switch, other than that it's been a beast.You didn’t mention if a used machine was on the table but I’ve seen some very reasonable View attachment 246340low-use suitcase welders online. I picked this one up a few years back and couldn’t be happier. Accepts gas, uses the large spools and is not too heavy on the roll around cart.lol I I basically got it for free. I had helped a friend that worked at a storage facility and had cleaned out a unit. She gave me several older analog O-scopes since I knew how to set them up. I had been using a cheap HF welder and experienced all the disappointments listed above. Low duty cycle, 15 min cool down period, and wanted to upgrade. Looked on CL and lo and behold a guy was looking to swap his welder for(you guessed it) an O-scope. What are the odds? 12 yrs later still making dimes.

Out of curiosity Jan I did call a welding shop a few weeks ago. Since parts aren't available, their "guess" would be 2 to 300 bucks to mod and install a rectifier.... and that's if they'd even take it in for work... which wasn't guaranteed.Just putting it out here

Hauling the old one to a shop having them install new rectifier bridge ??

If you say so Sir ..But rectifiers are often " the Brute " in a electric system .Out of curiosity Jan I did call a welding shop a few weeks ago. Since parts aren't available, their "guess" would be 2 to 300 bucks to mod and install a rectifier.... and that's if they'd even take it in for work... which wasn't guaranteed.

can take a beating and mostly does not matter that much if one installs a larger bridge .

I would be surprised if there is no smaller new startup company that can make it happen.

Rewinding shop perhaps for larger motors

That quotation sends signals of " Not interested " or wanting to sell new equipment.

and sure that happens -- they are free chose business model and can have the Order book full.

Can be more intersted selling 50 units per order to bigger customers.

That is known here it is not possible tell customers that are calling "Get the h..l outta here "

But asking $ 200 300 when a new equipment costs about the same sends signals of that.

Having said that I have never looked inside one of these and there can be other electronics involved

If it was me here I would spread the word at bike nights + friends and so.

Who knows about this -- A Can do man .. Always somethings that comes Up Straight talk " don't go there " Sometimes it can take while

And at the end new Equipment is bought anyhow. But surprosingly effective . There can be people trading in used equipment and have parts.

Furthermore equipment a bit older can be easier to repair

New toy showed up.

So let me preface this with an update on my foot.... I'm still under Docs orders to stay off it for another 2-3 weeks. He doesn't want to risk the incision opening back up 'tween now and then. Now that the staples are out, I find I can fit a flip flop over the bandage... and using a cane I'm somewhat mobile. 3 days of that now and no leakage, so I don't think I'm overdoing it.... even if it's not really in the spirit of following Dr's orders. Btw... you haven't really lived 'till you've had 25 staples (  ) removed from the bottom of your foot. They had to peal me off the ceiling to get to the last few.

) removed from the bottom of your foot. They had to peal me off the ceiling to get to the last few.

So yeah... this (still) is a slow roll.

Lifting the 65lb corpse of the Hobart off it's cart and out of the basement was beyond what I was willing subject my foot to, so I disassembled in situ. Carried the pieces out to the trash can one manageable bit at a time.

One problem I've always had with the cart was I built it too small. The Hobart took up all the space and didn't leave room for the gas bottle. Took a grinder and cut off the extra bits on the cart and the new welder and bottle now fit perfectly. While I was at it, I went ahead and cut new wood for it and gave it a fresh coat of paint.

So here's what I got to show for 3 days of balancing on one foot. About 3 hrs worth of actual work.

Since it's a new toy, I went ahead and sprung for a new regulator with a flowmeter to boot...

Shoulda took a pic of the Hobart before I started.... oops. Here's an old pic with it sittin' in the background. You can see how I screwed up and had the bottle high on the back of the cart as an afterthought.

With a little luck I'll get it all plumbed and burnin' wire tomorrow.

) removed from the bottom of your foot. They had to peal me off the ceiling to get to the last few.

) removed from the bottom of your foot. They had to peal me off the ceiling to get to the last few.

So yeah... this (still) is a slow roll.

Lifting the 65lb corpse of the Hobart off it's cart and out of the basement was beyond what I was willing subject my foot to, so I disassembled in situ. Carried the pieces out to the trash can one manageable bit at a time.

One problem I've always had with the cart was I built it too small. The Hobart took up all the space and didn't leave room for the gas bottle. Took a grinder and cut off the extra bits on the cart and the new welder and bottle now fit perfectly. While I was at it, I went ahead and cut new wood for it and gave it a fresh coat of paint.

So here's what I got to show for 3 days of balancing on one foot. About 3 hrs worth of actual work.

Since it's a new toy, I went ahead and sprung for a new regulator with a flowmeter to boot...

Shoulda took a pic of the Hobart before I started.... oops. Here's an old pic with it sittin' in the background. You can see how I screwed up and had the bottle high on the back of the cart as an afterthought.

With a little luck I'll get it all plumbed and burnin' wire tomorrow.