All talk and no pics makes the forum members angry, so here's a few pics taken right before I shut down for the night...

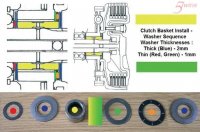

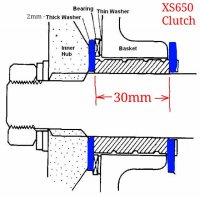

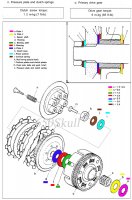

Swingarm has a center zerk and bronze bushings installed (what a PITA!). Tapered head bearings are in, forks are disassembled and dampening rods are on their way to the suspension guy to see if they can work with his emulators. Wheel bearings are installed. Clutch is pulled and awaiting inspection/overhaul. Points plate, rod and advance assembly is pulled and awaiting overhaul. EX500 carbs are back together and awaiting a bench sync and I need to figure out the choke pull (I'd like to do a mini handle but I can't find a short cable and knob??)

Tomorrow will be dedicated to welding up those thin frame areas. Anything else I should do to the frame while the welder is out? I recall someone saying it's good to weld up some of the frame overlap joints, but I can't recall specifics.

Swingarm has a center zerk and bronze bushings installed (what a PITA!). Tapered head bearings are in, forks are disassembled and dampening rods are on their way to the suspension guy to see if they can work with his emulators. Wheel bearings are installed. Clutch is pulled and awaiting inspection/overhaul. Points plate, rod and advance assembly is pulled and awaiting overhaul. EX500 carbs are back together and awaiting a bench sync and I need to figure out the choke pull (I'd like to do a mini handle but I can't find a short cable and knob??)

Tomorrow will be dedicated to welding up those thin frame areas. Anything else I should do to the frame while the welder is out? I recall someone saying it's good to weld up some of the frame overlap joints, but I can't recall specifics.